BACKGROUND

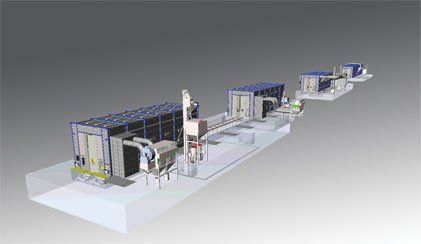

Proposal drawing of booths layout.

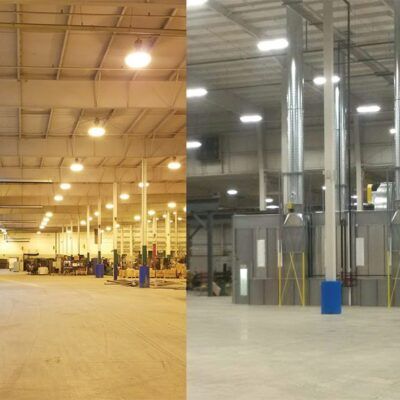

Vertex Rail is the first company to enter the railcar manufacturing sector in over 50 years. With such formidable stakes, they wanted to land a solid first step into the industry. One of the major bottlenecks happened in its blasting and painting division.

Vertex needed the new facility to churn out railcars in high volumes. To drive production, they looked to automate its blasting and painting process. They partnered with BlastOne due to our experience and unique partnership with automation companies.

SOLUTION

BlastOne’s proposal consisted of 4 in-line booths to maximize space and finishing efficiency, while still allowing room for future expansion.

BlastOne’s proposal to Vertex included the following components:

Fully automatic blasting system using Blastman robotics

Blastman robotics are the perfect solution for blasting rail car exteriors.Manual blast booth to touch up and blast car interiors

Full downdraft paint booth

High temperature cure booth with AquaTec

RESULTS

Vertex Rail’s entered into the railcar manufacturing market with enormous production capability with a fraction of typical finishing labor costs.

Fully automatic robotic blast booth

State-of-the-art dust collection system

KNOWLEDGE & LEARNING

5 CRITICAL COMPONENTS OF A BLAST ROOM

BLAST ROOM PREVENTATIVE MAINTENANCE

4 WAYS TO CURE PAINT FASTER

CASE STUDIES

Contact BlastOne

We love to talk to customers and help them make the best decisions when purchasing equipment.

You can reach us via our Live Chat, Email, Phone, and Online Form.

My Account

My Account