BACKGROUND

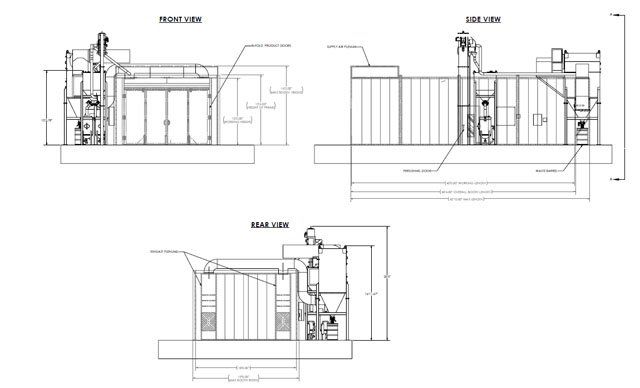

Finished blast booth with oscillating cross conveyor.

Tronair is a world-leading manufacturer of aircraft ground support equipment. Located in Toledo, OH, Tronair experienced rapid growth with recent acquisitions. They purchased a new facility to manufacture and transport equipment from three other locations.

Tronair needed to convert its 120,000 sq ft facility into an efficient manufacturing center. Their goal was to see a 50% increase in productivity compared to previous facilities. Additionally, Tronair wanted multiple blasters working at a given time.

SOLUTION

Proposal drawing of the finishing facility.

BlastOne designed and engineered a custom blasting and painting facility for Tronair.

It included the following elements:

Custom abrasive blast room

Built-in abrasive recovery system

Unique paint cure mode to apply automotive finishes equipped in paint booth

RESULTS

We designed the finishing facility in line with the rest of Tronair’s manufacturing equipment. The design allows for a seamless production process. We completed the overall project within 16 weeks.

Tronair’s newly minted finishing facilities can blast and paint three different brands of ground support equipment under one roof.

(Left:) Tronair’s newly acquired facility before BlastOne’s proposal. (Right:) Facility after the installation of two booths.

KNOWLEDGE & LEARNING

5 CRITICAL COMPONENTS OF A BLAST ROOM

BLAST ROOM PREVENTATIVE MAINTENANCE

4 WAYS TO CURE PAINT FASTER

CASE STUDIES

Contact BlastOne

We love to talk to customers and help them make the best decisions when purchasing equipment.

You can reach us via our Live Chat, Email, Phone, and Online Form.

My Account

My Account