3 Problems when you flood the pusher line with abrasive

- You waste abrasive

- You impede the blast by compromising optimal pressure

- You compromise the substrate’s profile

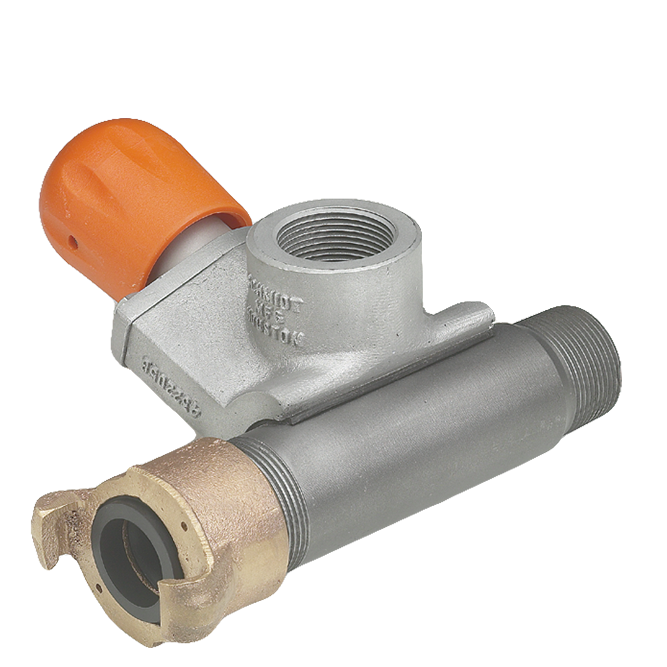

How to properly dial in and set the Microvalve

- Completely close the MicroValve – and then open it 3.5-4 dial rotations

- Hold the nozzle up to the light, allowing the abrasive to exit the blast stream into the air. You should be able to see a small bluish jet stream protruding at the very tip of the blast nozzle.

- If there is too much abrasive, the bluish jet stream will not be visible and the noise of the nozzle will soften and dampen.

- If there is too little abrasive, the bluish jet stream will also not be visible, but the sound of the nozzle will produce a higher shrill (scream) than what is heard when proper abrasive exits the venturi.

We want to know what questions, challenges, and problems you’re facing – either with blasting or painting – that we may be able to solve.

If you find our insights helpful, please subscribe and share our channel.

My Account

My Account