Heavy Duty Sand & Abrasive Blast Nozzles

ABRASIVE MEDIA SANDBLASTING NOZZLES

BlastOne is a leading supplier of abrasive blasting nozzles for industrial blasting and painting contractors worldwide. If you need help selecting the best nozzle for your project, here’s a few ways we can help:

- See our Blast Nozzle Comparison Guide. We compare virtually all industrial nozzle types and show where they best suited. We also have a short Blast Nozzles Overview Video.

- Call one of our sales specialists at 1-800-999-1881.

- Chat with us using the chat bot in the bottom right corner of this page.

Whether you’re looking to compare and contrast Tungsten Carbide vs. Silicon Nitride, you’re seeking a nozzle that reduces noise, or you’re looking for a nozzle to reach inside a hole, we have the resources to help you succeed. We look forward to serving you!

Showing 1–15 of 35 results

-

The Blast Ninja nozzle is an option for reducing the noise of blasting in certain applications. It offers price-leading economy for applications where production speeds are not critical. Product details are as follows:

- Sizes. Comes in #4, #5, and #6 orifices.

- Threads. Offered in fine or contractor thread in poly, brass, or aluminum threads.

- Liner options. Available in tungsten carbide or extended-life silicon nitride.

-

The SnakeBite XP is the high-performance nozzle used in the highly successful SnakeBite XQ silenced configuration. As the XP uses a simple bump cap on the end (instead of the silencer), it does not have the noise and thrust reduction of the XQ. It is very fast and exceeds the performance of our hyper nozzle. Details as follows:

- Performance:

- The advanced modeling used when designing this Snakebite XP hyper nozzle has taken blasting performance to a whole new level. The refined internal geometry coupled with the non-silencing bump-cap produces very fast cleaning speed indeed.

- Liner:

- The new internal geometry when combined with the silicon nitride composition extends usable life greatly.

- Jacket:

- Anodized aluminum with ergonomic shape makes for a very comfortable grip.

- Sizes:

- Available in the following orifice sizes: 6, 7, 8, & 10

- Overall length varies from 10" to 13", depending on orifice size.

- Thread type:

- Available in standard 2" Contractor thread only. (See You May Also Like nozzle thread adapters below if you want to use with fine thread nozzle holders.)

- Performance:

-

Snakebite. The world's quietest blast nozzle!

- Up to 16dBA noise reduction

- Up to 45% less fatigue compared to standard blast nozzles

- Improved nozzle geometry

- New technology quick-connect nozzle silencer

- Durable and lightweight Silicon Nitride nozzle and silencer liner

- Slimline ergonomic nozzle jacket

- Standard contractor nozzle inlet thread

- 2 versions available

- Standard Pressure Nozzle effective between 90-110 psi

- Low Pressure (LPS) Nozzle effective between 70-90 psi

- FREE TRIAL AVAILABLE

-

All the power. Half the size!

- Up to 16dBA noise reduction

- Up to 45% less fatigue compared to standard blast nozzles

- Improved nozzle geometry

- New technology quick-connect nozzle silencer

- Durable and lightweight Silicon Nitride nozzle and silencer liner

- Slimline ergonomic nozzle jacket

- Standard contractor nozzle inlet thread

- 2 versions available

- Standard Pressure Nozzle effective between 90-110 psi

- Low Pressure (LPS) Nozzle effective between 70-90 psi

- FREE TRIAL AVAILABLE

Act quick! Limited supply.

-

BNSBXQ10-1

- WATCH VIDEO IN THE IMAGE SLIDER

- Highest productivity hand held blast nozzle available

- Over double the productivity of a #8 high performance blast nozzle with less operator fatigue

- Half the thrust of other #10 blast nozzles available - Feels like you're blasting with a #7 nozzle

- Up to 16dBA noise reduction - That's 75% quieter!

- Ideal for blasting acres of steel such as storage tanks, bridges and ship hulls

- Standard contractor nozzle inlet thread

- Delivers faster cleaning rates and increased profit by reducing project duration

- Requires 750cfm compressor

- FREE TRIAL AVAILABLE!

BNSBXQ10-1- WATCH VIDEO IN THE IMAGE SLIDER

- Highest productivity hand held blast nozzle available

- Over double the productivity of a #8 high performance blast nozzle with less operator fatigue

- Half the thrust of other #10 blast nozzles available - Feels like you're blasting with a #7 nozzle

- Up to 16dBA noise reduction - That's 75% quieter!

- Ideal for blasting acres of steel such as storage tanks, bridges and ship hulls

- Standard contractor nozzle inlet thread

- Delivers faster cleaning rates and increased profit by reducing project duration

- Requires 750cfm compressor

- FREE TRIAL AVAILABLE!

-

- Replacement silencers for the SnakeBite family of blast nozzles

- Up to 45% less operator fatigue

- Up to 16dB noise reduction

- 2 versions available

- Standard Pressure Silencer effective between 90-110 psi

- Low Pressure Silencer (LPS) effective between 70-90 psi

-

This general-purpose nozzle was designed for everyday use, only better - it lasts longer and offers greater ease of use! It features the following:

-

Performance characteristics:

- Venturi design provides up to 40% faster production than straight bore versions.

-

Thread type & Orifice Size options:

- Contractor 2" (50mm)

- Fine 1-¼" (32mm)

- Orifice size options: 3, 4, 5, 6, 7, 8

-

Liner:

- Silicon nitride, provides longer life and lighter weight than tungsten carbide.

-

Jacket:

- All-polyurethane – reduces ‘jams’ in metal nozzle holders

- Shock absorbent, lightweight urethane jacket protects the blast nozzle liner

-

Design:

- 1" throat entry on #3 and #4 Contractor thread AND all Fine thread options

- 1-¼" throat entry on #5, 6, 7, and 8 Contractor threads

-

Additional notes:

- Approximately half the weight of standard tungsten carbide nozzles.

- Although the up-front cost is higher than tungsten carbide, the longer life Ultra-Tuff offers same or better total cost of ownership.

-

Performance characteristics:

-

The blast nozzle for the ConeBlast Internal Pipe Blaster is a key element in controlling the volume of air/abrasive flow. It is subject to high wear and is a common replacement part. Additional details:

- Sizes. Two sizes are available, depending on the capacity of your compressed air source.

- BNAFR8 requires 250CFM

- BNARF10 requires 400CFM

- (The size variants are interchangeable.)

- Construction. These nozzles are made from tungsten carbide. For large pipe-cleaning projects, contact us for options on longer-life versions.

- Sizes. Two sizes are available, depending on the capacity of your compressed air source.

-

Designed with an extra-long venturi and concentrated blast pattern, the Hyper (aka XL or Saber) nozzle increases performance substantially. Additional details as follows:

-

Performance characteristics:

- Up to 30% faster coating removal and/or

- Allows greater stand-off distance (reduces need to bend over when blasting tank floors, allows greater reach, etc.)

-

Thread types & Orifice Size options:

- Contractor 2" (50mm)

- Fine 1-¼" (32mm)

- Orifice size options: 5, 6, 7, 8, & 10

-

Liner:

- SiALON silicon nitride, provides longer life and lighter weight than tungsten carbide.

-

Jacket:

- All aluminum, non-slip knurled finish

-

Design:

- 1-¼" throat entry, extended venturi, 12 inches long

-

Performance characteristics:

-

Designed with a 60% larger blast pattern, the Raptor (aka Bazooka) nozzle makes short work of your large commercial blast / sweep blast / brush blast projects. Additional details as follows:

-

Thread types:

- Contractor (2") aluminum threads

- Fine (1-¼") brass threads

-

Liner:

- Silicon nitride, offers lighter weight and longer life than tungsten carbide.

-

Jacket:

- Urethane, for improved resistance to damage

-

Design:

- 1-¼" throat entry, extended venturi

-

Thread types:

-

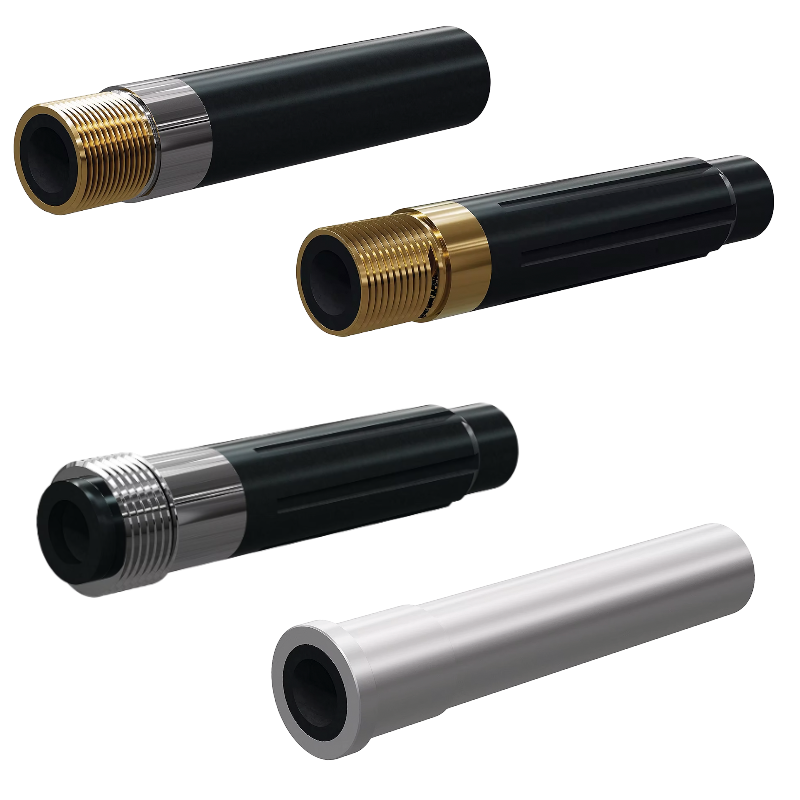

Standard Tungsten Carbide (aka TVP) blast nozzles are widely used and are a lower-cost, basic general-purpose nozzle with the following characteristics: Click for Buying Guide

- Performance characteristics:

- Venturi design offers up to 40% greater production than straight bore.

- Thread Types:

- 1-1/4" NPSM (32mm) brass fine threads

- 2" (50mm) aluminum contractor threads

- Flange type (unthreaded, and attaches to a blast hose with a standard blast hose quick coupling instead of a nozzle holder)

- Orifice Sizes:

- Contractor & Fine: 3, 4, 5, 6, 7, 8, 10, 12

- Flanged: 6, 7, 8, 10, 12

- Liner:

- Tungsten Carbide, provides longer life than disposable alternatives for industrial blasting projects

- Jacket:

- Contractor and Fine thread versions have poly jacket

- Flanged type is an all-aluminum jacket

- Design:

- 1" (25mm) throat entry for #3 and #4 sizes

- 1 1/4" (32mm) throat entry, for all other sizes

- Additional notes:

- Lowest up-front cost of any industrial blast nozzle.

- Higher weight and shorter lifespan than premium silicon nitride versions.

- Lower total cost of ownership, higher performance, and/or improved ease-of-use may be achieved with one of the premium nozzle options. See You May Also Like below.

- Performance characteristics:

-

The Water Induction Nozzle (aka WIN nozzle) is an economical way to enter the wet blasting market. Commonly used in smaller projects, it offers excellent water flow control. Additional Details:

- Use with standard dry blasting equipment. No modifications required.

- Connects to standard garden hose, or you can use a tank with a standard 12v pump if you need to add rust inhibitor to the water.

- Typically stocked with tungsten carbide liner and contractor threads, it is also available with silicon nitride liner and/or fine threads. Contact us for details.

-

- Curved "Banana" Blast Nozzle

- Made from Boron Carbide which is the longest lasting material used for blast nozzles

- Size listed is a #6, which is 3/8" internal diameter

- Has a Medium 3/4" Thread - Requires a special nozzle holder adapter

- Search for “nozzle thread adaptors” to select an adaptor to use with your existing nozzle holder, or contact BlastOne if you want a medium thread nozzle holder.

- Sold Individually

-

Effective solution for blasting in hard-to-reach areas such as:

- Inside of bolt holes

- Inside of close-fitting steel channels

- Difficult access structural steel, such as bridge supports, etc.

- Offers standard extension lengths from 10 to 60 inches, with other options available by special order.

- Can be used with most abrasives

- Attaches to blast hoses with standard 2-prong couplings (not nozzle holders)

- Nozzle is NOT included and shown for illustration purposes only. Requires junior size 3/8" NPT threaded nozzles. Choose the correct one for your application from our Tite-Space nozzle selection here.

- Female version requires only ¾" clearance.

- Male version requires only 1" clearance.

-

GRACO® SPECIAL PURCHASE - ECOQUIP FINAL CLEARANCE! These hoses and nozzles are top quality new condition, and work on all abrasive blasting equipment (not just EcoQuip). These special-purchase products include the following:

- EcoQuip “Replacement” blast hose assemblies, which include coupling / nozzle holder, control line, and a Schmidt® Response deadman handle, in both pneumatic and electric.

- EcoQuip “Extension” blast hose assemblies, which include couplings and control line, in both pneumatic and electric.

- EcoQuip "Bulk Hose", 50' sections of blast hose, without any accessories

- Graco blast nozzles in the following types:

- Standard (contractor thread)

- Hyper (contractor thread)

- SST (medium thread)

- Double Venturi (contractor thread)

A TIP ON WHEN TO REPLACE YOUR SAND BLAST NOZZLE

Even a very small increase in blasting nozzle size will result in a very large increase in ‘air and abrasive consumption’. When a sand blast nozzle has worn 1/16” (2mm) larger, it is time to be replaced. Use an abrasive blast nozzle size analyzer kit to check your nozzle regularly (we recommend at least ONCE PER WEEK). You’ll be surprised how much your production decreases with a worn sand blasting nozzle! Wet blasting & WIN (Water Induction Nozzles) also available

SANDBLASTING NOZZLES & ABRASIVE BLAST NOZZLES

NOTE: Efficiency drops 1.5% for every 1 psi below 100 at the sand blasting nozzle. This means a 14% efficiency drop at 90 psi, 26% efficiency lost at 80 psi and almost half lost at 60 psi. Efficiency goes up as pressure increases. 120 psi improves performance by 30%. Actual efficiency increase/ decrease will vary depending on abrasive type and size, blast nozzle type, size and wear, hose sizes and wear, temperature, moisture content of compressed air, etc. Use a abrasive wet or dry blast nozzle pressure gauge to measure air pressure at the nozzle. Make allowance for increased air consumption due to sandblast nozzle wear, air leaks, breathing airline filter, respirator breathing air and any pneumatic equipment using air from the compressor. A good rule of thumb is to use a compressor twice the capacity of the grit blast nozzle consumption.

My Account

My Account