COMPANY BACKGROUND

CS Wind Corporation is a wind tower manufacturer with global expertise, reliability, and quality. Their mission is: “We create a bright future for humans and nature.”

WHY CS WIND CHOSE BLASTING ROBOTICS

CS Wind searched for an effective method to abrasive blast the externals of new wind tower sections.

Other options considered for this project included wheel blasting technology. However, as a result of the high standards for surface cleanliness and roughness, wheel blasting was no longer an option. CS Wind chose Blastman Robotics as the partner for blasting automation.

PROJECT OBJECTIVES

Abrasive blast wind tower sections, fast, consistently and with minimum human labor intervention while maintaining the required specifications cleanliness and roughness that allowed the subsequent coating system to last for years.

Advantages of Automated

Considerable savings in production costs

Increased production capacity

Remarkable healthy and safety implications

Freedom to use any abrasive material

Desired surface cleanliness and roughness

Slight surface shaping by controlling the blast pressure

Working lifts and platforms are not needed

Increased fatigue strength of specific welded joints

SOLUTION

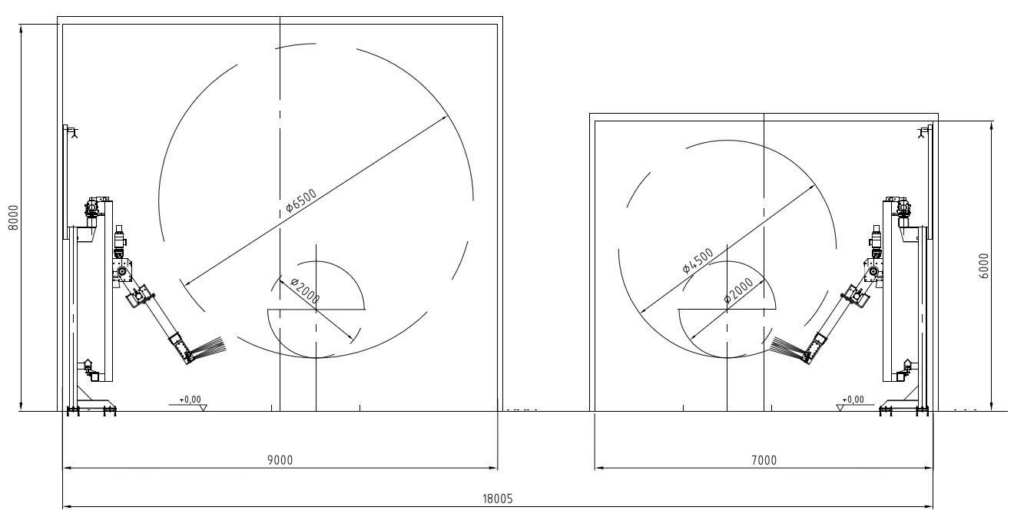

CS Wind installed three surface treatment lines comprised of an abrasive blasting chamber and a painting room. Subsequently, each abrasive blasting chamber has one Blastman B12 robot with two ¾” nozzles.

The Blastman B12 Blasting Robot is mounted to tracks on the wall and has a 4-axis arm that can extend and swivel easily. Meanwhile, each arm supports two large blast nozzles. Typically, this robot works best on simple structures like wind towers.

Firstly, we considered material handling. We used specialized product carts. This system contains in-ground tracks and purpose-built rollers to position the tower section precisely.

Moreover, the robot is programmed to coordinate the rolling of the tower in conjunction with the blast nozzle. In this facility, blasting is done sector by sector: the robot moves from one end to the other, where the roller bed rotates the tower element. This leaves a slight overlap on the blasted sector before the robot returns. Concurrently, the tower element rotates around.

RESULTS

CS Wind’s North American wind tower finishing facility is highly productive, with a blast cleaning capacity of over 2500 ft2/hr using robots, which is 10x faster than manual blasting. The steel grit used for the blasting achieves the required surface cleanliness and profile, but CS Wind can easily switch abrasives for greater versatility in the long-term. Robot programming allows for five operational modes, including roller bed rotation and automatic or manual touch-up using a joystick drive.

ROBOTIC ABRASIVE BLASTING MYTHS

THE TRUTH BEHIND COSTS, EXPERTISE NEEDED, RANGE OF APPLICATIONS AND FACILITY REQUIREMENTS FOR BLASTING ROBOTS

CASE STUDIES

Contact BlastOne

We love to talk to customers and help them make the best decisions when purchasing equipment.

You can reach us via our Live Chat, Email, Phone, and Online Form.

My Account

My Account