Glass Abrasive Blasting Abrasive Supplier

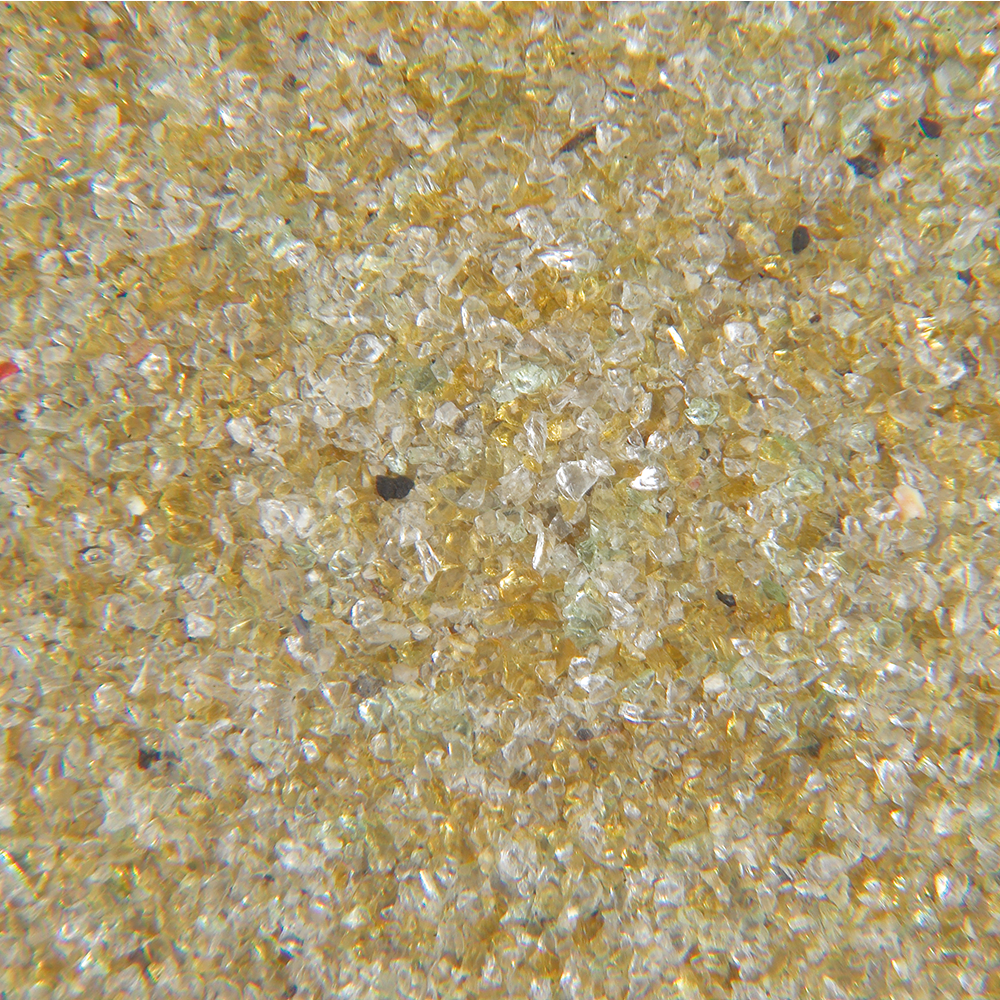

Manufacturers of glass bead blasting abrasive media, use recycled glass as a feedstock. Recycled glass for manufacturing is ground into a powder and heated to melting point. This causes the powder particles to change from a jagged shape to a rounded sphere. Grading into select sizes takes place after heat processing and forming into spheres.

Glass bead blasting abrasive media is less aggressive than sand or steel grit. It does not remove heavy coatings and rust. The main application is on softer, non-ferrous metallic surfaces. Glass produces a bright satin finish on materials such as stainless steel and aluminum. The finish on items blasted is even and is ideal for items that will not be further coated.

Other applications for glass bead blasting include cleaning, e.g., engine heads for reconditioning, deburring, e.g., taking rough edges off punchings, peening of high stress components (to expose any cracks likely to be hidden surface contamination) and surface extension (preparing a flat surface for enameling or lacquering by increasing the surface area that they can bond onto).

Showing the single result

-

Crushed and Glass Bead Blasting Abrasive Media, SKU: P-CG. Perfect for steel profiling, available in various grades & sizes. Not for aluminum/stainless.

- General Purpose abrasive used for Sandblasting

- Angular shape creates a profile on steel

- Not Recommended for blasting on stainless or aluminum

- Comes in many different grades and packaging sizes

- Non-Recycling

Items that are often blasted with glass bead include food processing machinery, abattoir equipment, stainless steel platforms and walkways and architectural fabrications. This media is iron free and will not stain the surface, either from impingement or if retained in an inaccessible area that is difficult to remove spent abrasive from. Blasting with glass bead has a slower production rate than with more aggressive sandblasting media. Normally this isn’t a problem as the surface area requiring blasting is usually limited.

Available in a range of sizes – from #20 – 30 to #270 plus. Special grades are available for military specification and peening.

My Account

My Account