BACKGROUND

Since 1891, Union Tank Car Company, provides high-quality equipment and comprehensive tank car services to our customers throughout North America. They needed a high production blast room for refurbishment of railcars, focusing on lining and coating.

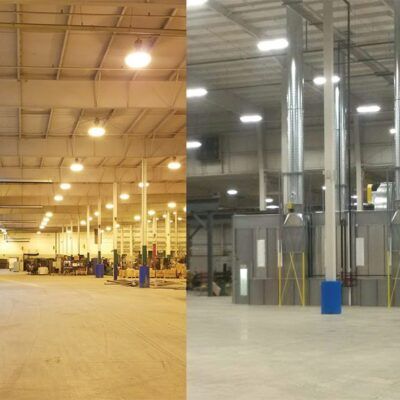

UTLX facility prior to blast room installation

Tank car linings serve a main function:

To protect the commodity from contamination by the base metal of the tank or hopper car

UTLX had an aging wheel machine at one of their facilities in Arkansas that needed to dramatically increase its production, but couldn’t afford to be out of service for a long time.

SOLUTION

BlastOne worked with UTLX to replace the old wheel machine—a now out-of-date way of performing surface preparation on railcars—with a new robotic blast room inside the existing facility.

While waiting for the robotic components to arrive, we built the blast room initially for manual blasting. This limited production downtime and had temporary access platforms for operators. Later, we removed these platforms once the robotic components were in operation.

Underfloor Pit Construction process

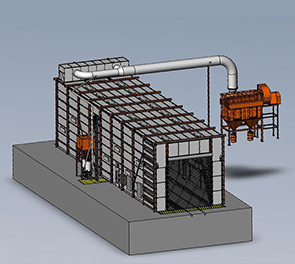

Rendering Blueprint of Blast Booth Installation

RESULTS

Union Tank Car (UTLX) now has a state-of-the-art robotic blasting facility which gives them a substantial competitive advantage. The cycle time and subsequent cost reduction gives them excellent return on investment, and the quality and consistency of the blast process provide further key advantages.

Blast room outfitted with temporary access platforms for manual blasting

Installation of robotics into blast booth

Large high efficiency dust collectors installed outdoors

Installed, blast-ready robot

Blast room under floor recovery system assembly in progress

Interior of blast room with built-in robotic blasting unit

Stair case leading up to the temporary access platform

Completed railcar robotic blasting job

Complete Blast Room ready for action, prior to robot installation

KNOWLEDGE & LEARNING

5 CRITICAL COMPONENTS OF A BLAST ROOM

4 WAYS TO CURE PAINT FASTER

THE PROPER EQUIPMENT FOR EACH COATING

CASE STUDIES

Contact BlastOne

We love to talk to customers and help them make the best decisions when purchasing equipment.

You can reach us via our Live Chat, Email, Phone, and Online Form.

My Account

My Account