PROJECT SCOPE

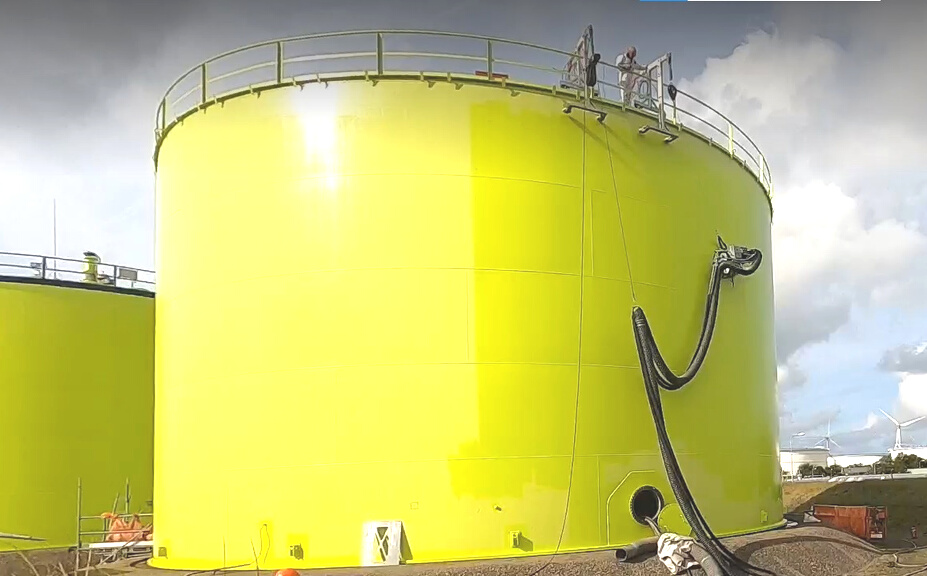

Terminal: Massvlakte Olie Terminal (MOT)

Location: Rotterdam, NL

Object ID: TK 403

Tank Height: 39 ft (12m)

Tank diameter: 65 ft (20m)

Coating contractor: Van der Ende

Total surface coated: 9246 ft2 (859 m2)

Type of coatings used: Sigmacover 350 & Sigmacover 456 (Intermediate), SigmaDur 550H (topcoat)

THE PREVAILING CHALLENGE

Maintaining a vast tank, high above the ground, isn’t a task for the faint-hearted. Skilled paint crews would traditionally, from their mobile cherry pickers or gondolas, apply chosen anticorrosive coatings through methods of spraying, brushing, or rolling. Depending on the tank’s size and the coating’s intricacy, this aerial task could stretch up to a month.

THE INNOVATIVE TURN

October 2021 marked a significant shift in this tradition at the Maasvlakte Oil Terminal. Qlayers, armed with their groundbreaking 10Q coating robot, embarked on a project to coat a colossal 65ft (20m) diameter tank. The mission was clear: replace the traditional, often grueling, manual process with an innovative robotic solution.

REMARKABLE OUTCOMES

With Van der Ende by our side and the 10Q robot at the forefront:

- Surpassing Speeds: The robot showcased an impressive application pace, clocking in at 1646 ft2/hr (153 m²/hr)—about 3.5 times more efficient than conventional methods.

- Enhanced Safety: The times workers spent operating from precarious heights dropped by an estimated 75%, dramatically improving the project’s safety standards.

- Precision Perfected: Thanks to the 10Q robot’s patented application hood, the tank now boasts an impeccable spray finish, elevating its aesthetics with minimal overspray.

In The Words Of An Expert

Maasvlakte Olie Terminal as an organisation does have a strong focus on preservation of the environment and is always searching for improvements and good initiatives to prevent people and environment from being exposed to toxic wastes and extreme physical conditions. Coating process is currently done manually with rollers in man baskets. Painters are exposed to heavy physical work in difficult conditions working on heights painting 3x 5700 m2 by hand. An automated solution would therefore be beneficial for people and environment.

As one of the first in line, Maasvlakte Olie Terminal proposed to execute pilots with the coating robot at their premises initially on some smaller tanks. This was done in 2020. The pilot was reasonably successful despite the expected challenges

working in the field. However development went on and several trails were carried out on other terminals before Qlayers returned to Maasvlakte Olie Terminal in 2021. They showed an impressive improvement compared to the previous year. The operating speed had increased and a minimum number of coating deficiencies were found.

The process was carefully followed up by some of the MOT shareholders as well to full satisfaction. The operating speed, environmental and physical advantages meeting the required quality standards will definitely play an important role in the decision making process regarding future coating applications on tanks at Maasvlakte Olie Terminal.

~ Peter Kassels,

Manager Assets and Projects, MOT

Contact BlastOne

We love to talk to customers and help them make the best decisions when purchasing equipment.

You can reach us via our Live Chat, Email, Phone, and Online Form.

My Account

My Account