Industrial Coatings Airless Spray Tips Buying Guide

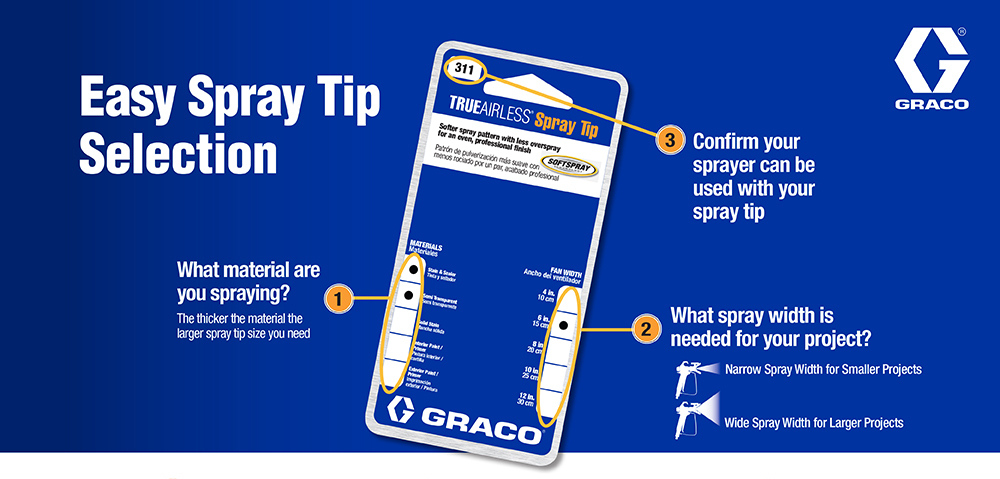

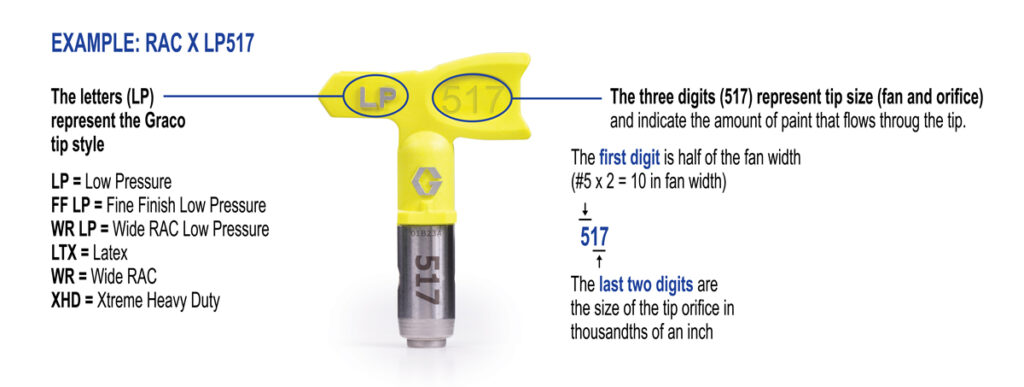

The right airless spray tip is an important tool decision dependent on the coating or paint you’ll be spraying. We offer top selections of Graco and Tritech spray tips, in a variety of orifice sizes sure to fit your project specifications.

Should you have any questions, reach out to our dedicated customer service team who are happy to help.

My Account

My Account