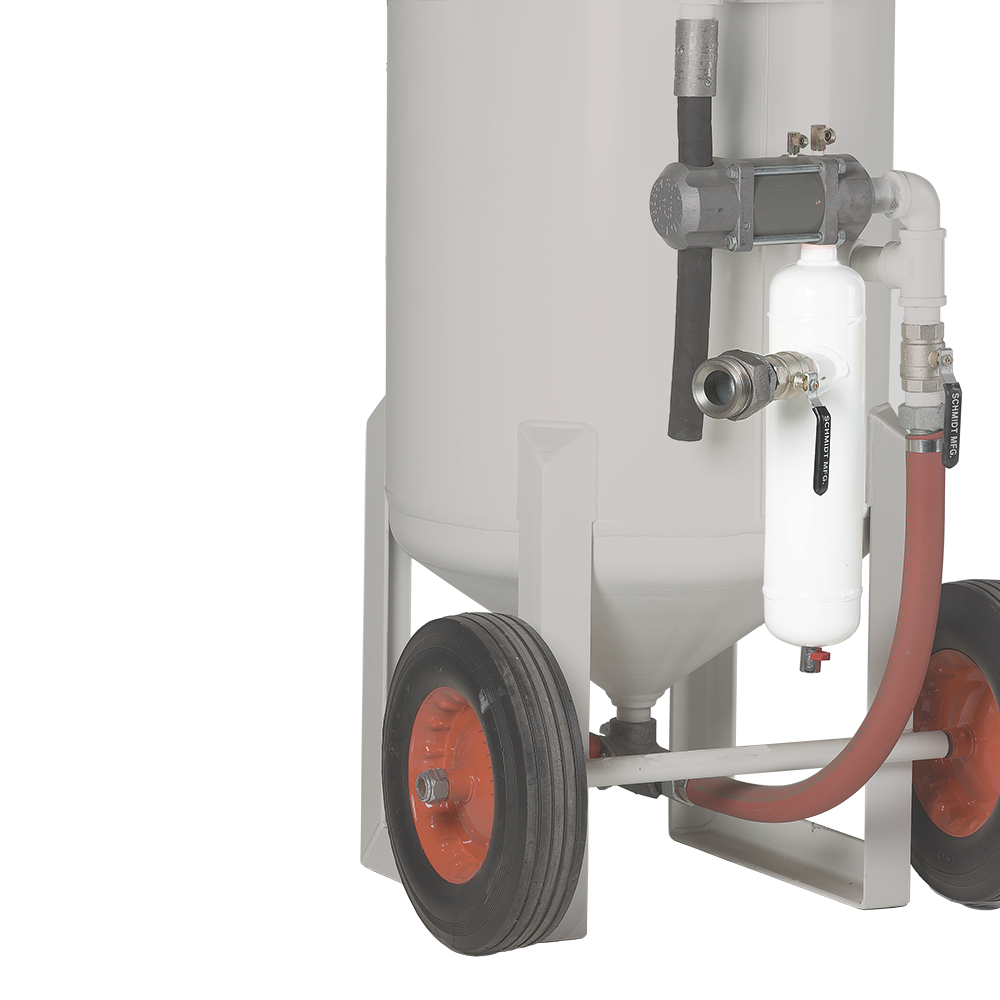

Inlet Airline Moisture Separator

Sku: P-AFMSHP

The MSH series of moisture separators are specifically for abrasive blasting. Few compressed air uses have as much volume demand as abrasive blasting. Therefore, separator design needs to be able to handle large air volumes. Of equal importance is minimal pressure loss. 1 psi pressure loss is a 1.5% efficiency loss. BlastOne Hi Flow moisture dry large air volumes without pressure loss. My Account

My Account