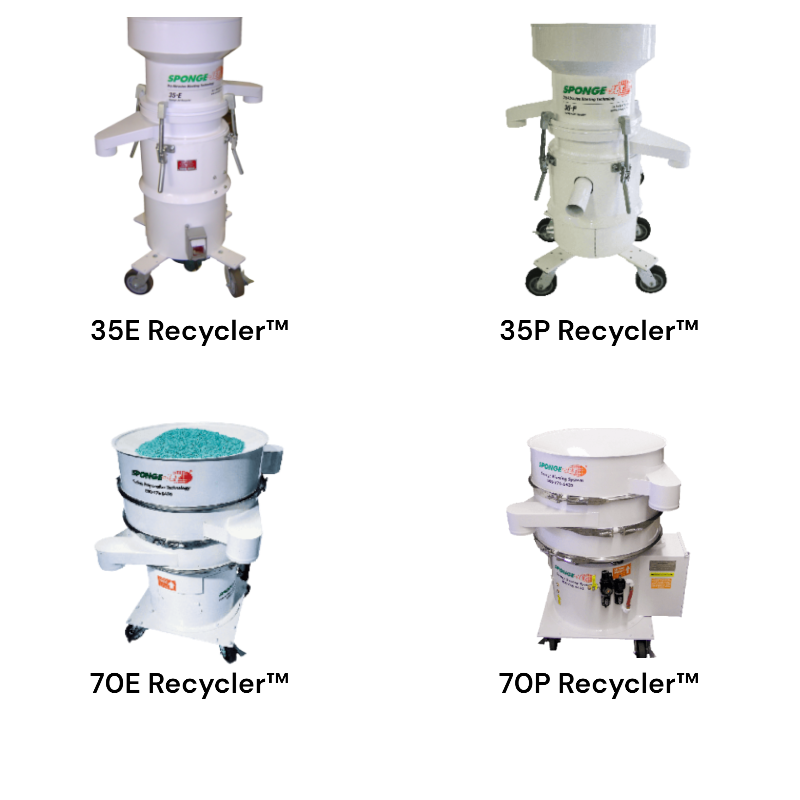

Sponge-Jet® Sponge Media Recyclers

Sku: P-SJRECYCLER

Sponge-Jet recyclers separate used media into 3 streams:- 1) Good reusable media.

- 2) Oversized waste.

- 3) Fine waste.

- 35 Series

- Compact. 300 lbs (pneumatic) or 325 lbs (electric)

- Designed with a rated speed of 15 lbs per minute

- Pneumatic version requires 40 cfm. Electric version requires a 20a breaker at 110v, 60hz.

- Includes 2 screens: A fixed #3 mesh on the top and a replaceable #16 mesh on the bottom. The bottom screen can be exchanged with other mesh sizes based on dust control needs.

- Available options:

- Additional screen mesh sizes

- Lifting frame

- Magnetic separator

- 50 Series

- Larger deck area than the 35 series

- This unit is designed for use with the B-Vac integrated system. It can be purchased as a stand-alone unit, but is rarely used as such.

- Increased production speed of up to 20 lbs/minute

- Includes 2 screens: A fixed #3 mesh on the top and a replaceable #16 mesh on the bottom. The bottom screen can be exchanged with other mesh sizes based on dust control needs.

- Available options

- Closed top, for use with vacuum recovery systems or overhead hoppers

- Additional screen mesh sizes

- Recycler stand

- Non-stock special order

- 70 Series

- High capacity model for increased processing speed and better dust removal

- Designed with a rated speed of 26 lbs per minute

- 600 lbs (pneumatic) or 650 lbs (electric)

- Pneumatic version requires 46 CFM. Electric version requires a 30a breaker at 110v, 60hz.

- Available options:

- Magnetic separator

- 2-screen version (Default is #3 top and #16 bottom unless otherwise specified)

- 3-screen version (Default is #3 top, #8 mid, and #16 bottom unless otherwise specified).

- Bottom screen can be replaced with other mesh sizes depending on dust control needs.

My Account

My Account