Hi, today we’re going to talk about the Mini BRS. What are some features, and what are the key benefits for using this machine in the field?

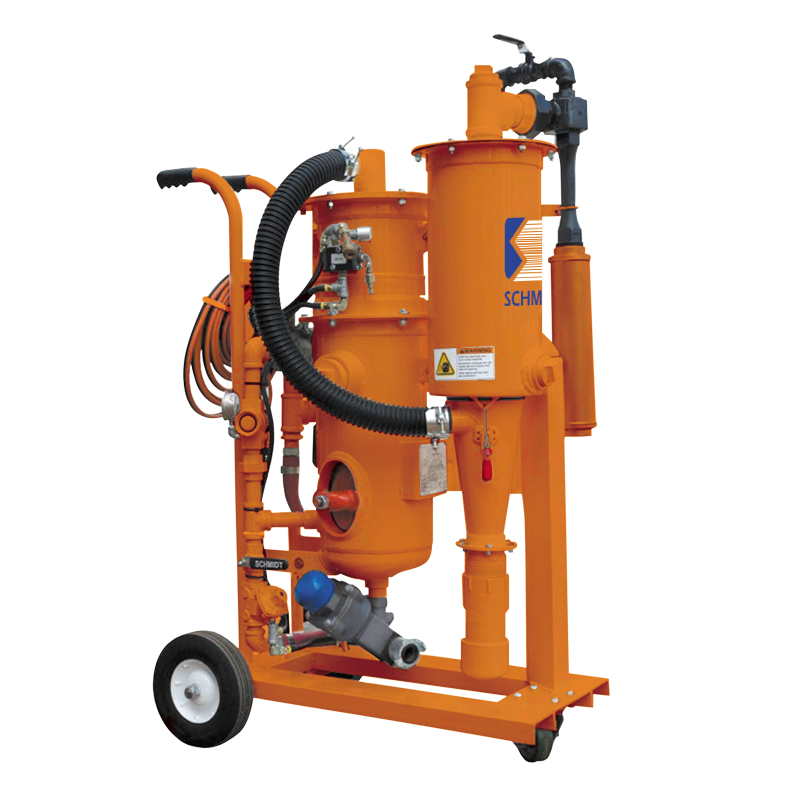

There are three main components of a Mini BRS. You have your standard blast pot set up.

Where you can regulate down air pressure and it goes out the bottom, a abrasive dropout and a cyclone reclaiming abrasive unit.

So how the system works, is you take your blast and vac head. You apply your blast and vac head to a surface with brushes, and there’s angled brushes and flat brushes.

You then start blasting and your blast air, comes through the back side of the nozzle.

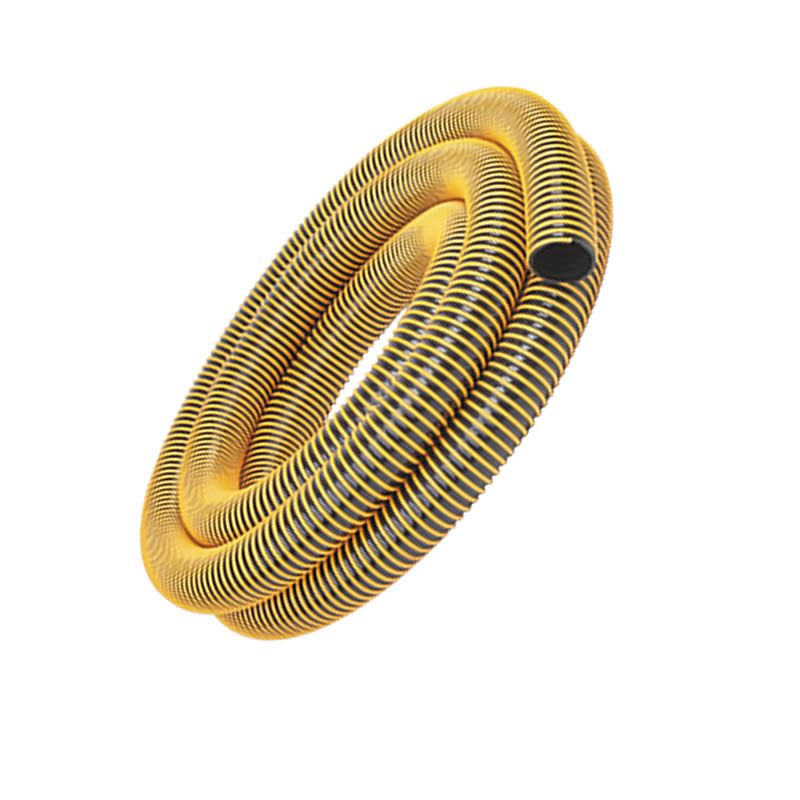

Your trigger is built into the handle, and your vacuum hose pulls all dust and abrasive out of the bottom side. From there when we get to the blast pot itself, as you have your air inlet over here.

From your air inlet, you supply your vacuum, which is an inductor assembly. It creates a venturi, and pulls vacuum through the cyclone, as well as the top of the blast pot so the whole unit is under vacuum when operating.

Your abrasive is then, pulled into this unit spun around cycloned out.

Heavy abrasive falls and reloads the blastpot, and dust and minute stuff gets pulled through the vacuum hose to the cyclone…

There’s a filtration filter in here, and another assembly where it helps separate the dust.

The dust then collects in the bottom of the cyclone and the filter collects the dust and exhausts everything through the main exhaust.

Some of the other features on this unit are its pulse system, so by using a solenoid in supplied air through the big black line, you are able to reverse pulse the filter, and it’s to put a puff of air backwards to the filter to clean out the dust, and then dust down here that settles down the bottom.

To change the filter you simply loosen the cam locks all the way around the unit. Detach and hinge out of the way, and as you can see in the unit itself. You then can pull this out of the way and get to the filter to change it there.

While operating the unit you’ll find that your suction weakens over time. So what this does is, tells you how clogged your filters are. And when it’s time to, actually pulse the unit.

My Account

My Account