3 TIPS TO EXTEND BLAST HOSE LIFE

TIP 1

Jon, an Account Manager at BlastOne, previously sold a new blast pot to a client who refurbishes large construction equipment. Included in the package was a 50-foot piece of our best-selling 1 ¼” 2-ply hose, which was all the length they needed.

CASE STUDY PROBLEM: they called afterwards and were having issues with the screws stripping out of the coupling that connected to the metering valve. They first thought it was a defective hose, but a new hose didn’t solve the problem. We then discovered that they were moving the hose a lot, to climb on and around the machines, and there simply was more strain on the coupling than the 2-ply could handle.

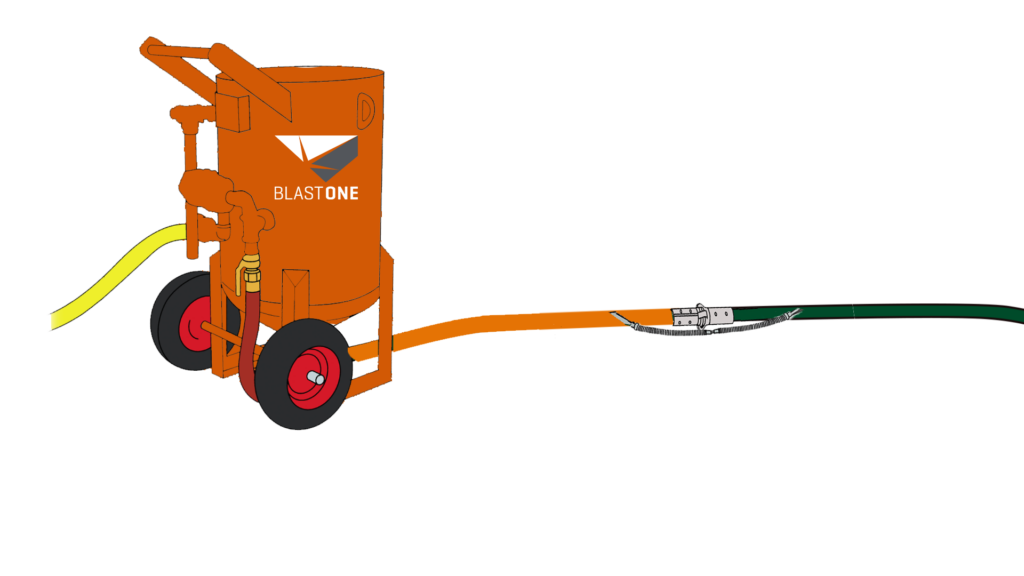

SOLUTION: To solve the problem, we gave them a 6-foot piece of 1 1/2” 4-ply hose to use as the first section, then connected the main 50’ hose to that. That solved the problem. Note that we used a 1 ½” hose first, which matches the typical 1 ½” pusher line. So, our first suggestion is, if you are having issues with the hose connection at the metering valve, try adding a 4-ply 1 ½” section.

BLAST ROOMS:

Our recommendation for blast room customers is similar to this. Ideally, blast pots are located outside the booth. Use a short section of 4-ply hose for the first section thru the wall, then you can use the more flexible 2-ply hose for the whip. This dramatically reduces wear at the point where the hose goes thru the wall.

My Account

My Account