Abrasive Metering Valves & Parts

The heart of any blast pot is the abrasive metering valve, which acts as the regulator to feed the blasting abrasive into the high pressure & high velocity compressed air stream. Regardless of the media type, money can be saved if your metering valve has fine-adjustment control. Too much abrasive will flood the airstream – this can actually slow down the blasting operation – as well as waste media. Too little abrasive will starve the compressed air stream, and slow production as well. Setting the abrasive metering valve precisely is imperative for high production abrasive blasting operations. BlastOne has represented the Schmidt by Axxiom Manufacturing line of metering valves for decades. Schmidt valves became the benchmark when they released the Thompson valve years ago, and have continued their tradition of innovation with the TeraValve and MicroValve III. These valves come in a variety of configurations and all set the standard for precision abrasive metering.

Showing 1–15 of 125 results

-

GV32400The Clemco Metering Under Pressure Kit gives operators easy abrasive adjustment while blasting. This optional kit mounts either directly to the PQV Pro valve or remotely on the signal line which makes it a flexible add on for any blast setup.

- Allows live abrasive adjustment while blasting

- Mounts on the PQV Pro valve or remotely on the signal line

- Improves operator control and fine tuning

- Designed specifically for PQV Pro valve systems

GV32400The Clemco Metering Under Pressure Kit gives operators easy abrasive adjustment while blasting. This optional kit mounts either directly to the PQV Pro valve or remotely on the signal line which makes it a flexible add on for any blast setup.- Allows live abrasive adjustment while blasting

- Mounts on the PQV Pro valve or remotely on the signal line

- Improves operator control and fine tuning

- Designed specifically for PQV Pro valve systems

-

DM22868The Clemco Millennium Valve Outlet Muffler Service Kit gives you the spare parts needed to keep the Millennium Valve breathing clean and running without interruption. This kit helps reduce noise, maintain airflow and prevent clogging in the outlet muffler.

- Replacement parts for the Millennium Valve outlet muffler

- Helps maintain airflow and reduce noise

- Quick swap parts for field or shop maintenance

- Keeps the Millennium Valve running steady

DM22868The Clemco Millennium Valve Outlet Muffler Service Kit gives you the spare parts needed to keep the Millennium Valve breathing clean and running without interruption. This kit helps reduce noise, maintain airflow and prevent clogging in the outlet muffler.- Replacement parts for the Millennium Valve outlet muffler

- Helps maintain airflow and reduce noise

- Quick swap parts for field or shop maintenance

- Keeps the Millennium Valve running steady

-

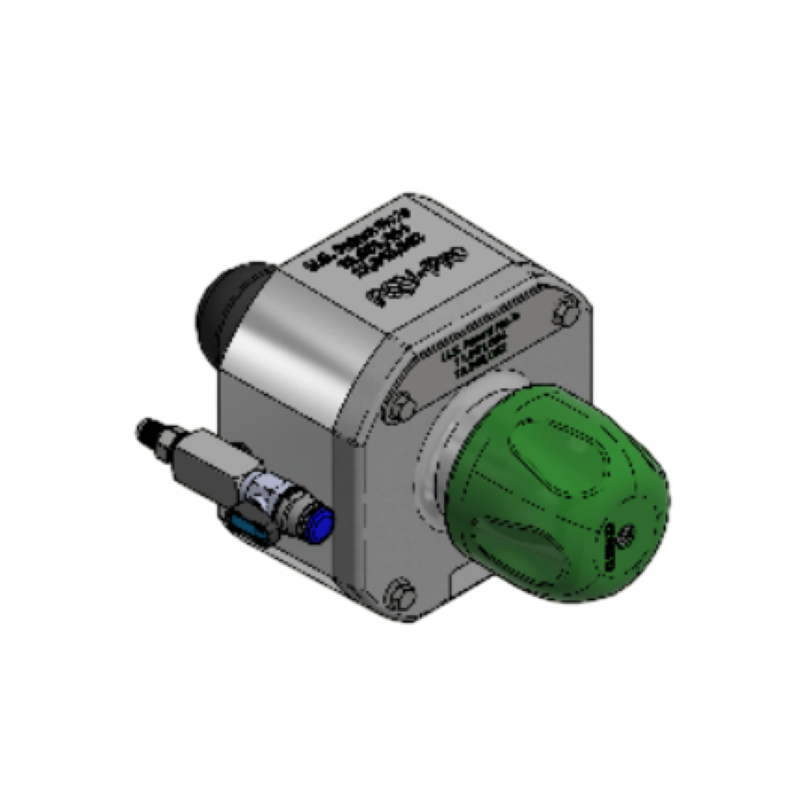

GV32118The Clemco PQV Actuator is the quick swap replacement actuator for PQV Pro valves and comes complete with seat and gasket. It installs on the pot in under ten minutes which makes it the go to service part when you need to keep a blast system running without downtime.

- Direct replacement actuator for Clemco PQV Pro valves

- Includes seat and gasket for full rebuild

- Installs in under ten minutes on the pot

GV32118The Clemco PQV Actuator is the quick swap replacement actuator for PQV Pro valves and comes complete with seat and gasket. It installs on the pot in under ten minutes which makes it the go to service part when you need to keep a blast system running without downtime.- Direct replacement actuator for Clemco PQV Pro valves

- Includes seat and gasket for full rebuild

- Installs in under ten minutes on the pot

-

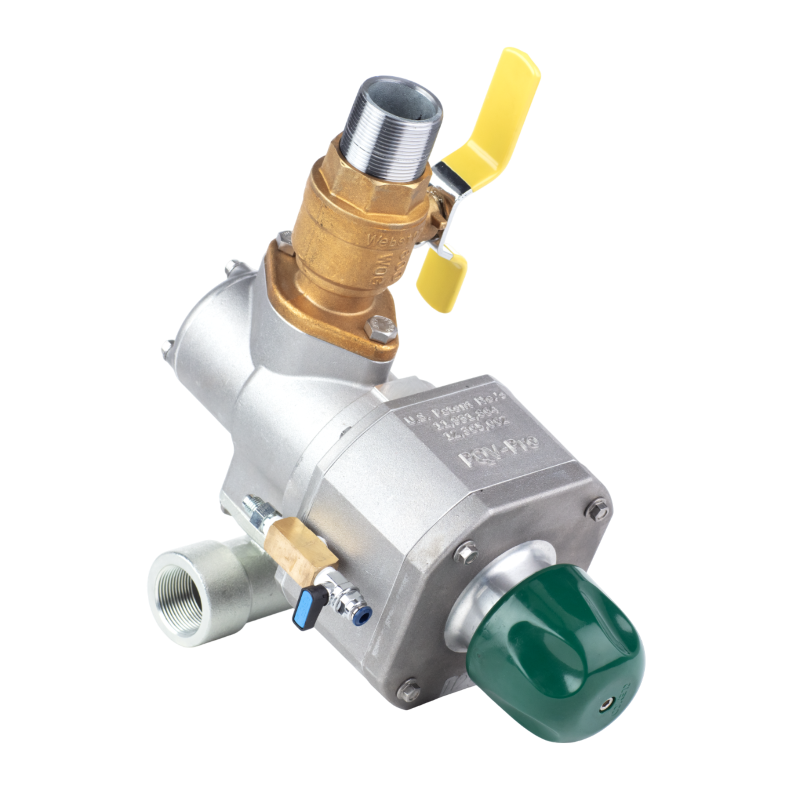

The Clemco PQV Pro Valve is Clemco’s newest premium pressure hold abrasive metering valve that replaces the GritWizard with tougher construction, easier service, and faster installs. The piston actuated design runs on a single signal line and can be serviced on the pot in under ten minutes, making it a solid upgrade for any blast machine or pressure blast cabinet.

- Replaces the Clemco GritWizard with newer, longer lasting tech

- Piston actuated design with only one signal line required

- Actuator swaps on the pot in less than ten minutes

- Available in multiple sizes with or without ball valve

-

BA31187Clemco 31187 Metering Knob Assembly is an OEM replacement part for MQV-Pro and Grit Wizard abrasive metering valves. It provides accurate control over abrasive flow and fits directly without modification.

- OEM metering knob assembly for Clemco valves

- Fits MQV-Pro and Grit Wizard models

- Controls abrasive flow from the valve

- Complete replacement assembly

- SKU: BA31187

- MPN: 31187

BA31187Clemco 31187 Metering Knob Assembly is an OEM replacement part for MQV-Pro and Grit Wizard abrasive metering valves. It provides accurate control over abrasive flow and fits directly without modification.- OEM metering knob assembly for Clemco valves

- Fits MQV-Pro and Grit Wizard models

- Controls abrasive flow from the valve

- Complete replacement assembly

- SKU: BA31187

- MPN: 31187

-

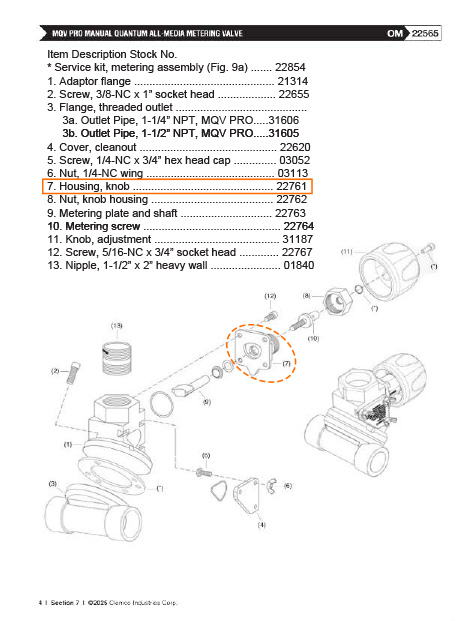

BA22761Clemco 22761 Knob Housing is a genuine OEM part for MQV and MQV-Pro valves used on Clemco pressure-release blast pots. It holds the valve knob assembly in place and allows for proper abrasive flow adjustment.

- OEM housing for MQV and MQV-Pro valve knobs

- Supports accurate abrasive adjustment

- Used in Clemco pressure-release blast pots

- SKU: BA22761

- MPN: 22761

BA22761Clemco 22761 Knob Housing is a genuine OEM part for MQV and MQV-Pro valves used on Clemco pressure-release blast pots. It holds the valve knob assembly in place and allows for proper abrasive flow adjustment.- OEM housing for MQV and MQV-Pro valve knobs

- Supports accurate abrasive adjustment

- Used in Clemco pressure-release blast pots

- SKU: BA22761

- MPN: 22761

-

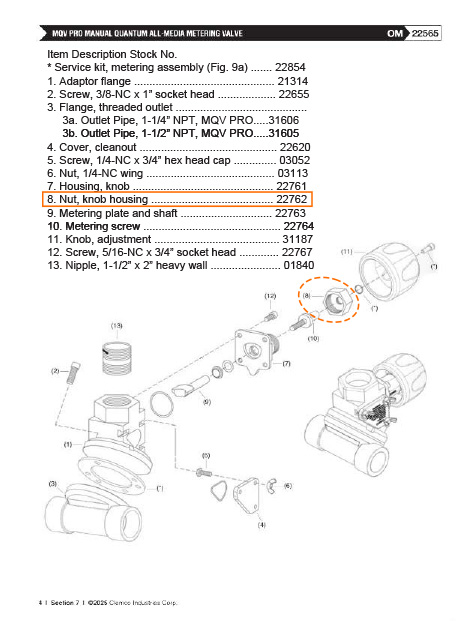

BA22762Clemco 22762 Nut is an OEM replacement part used in the knob housing of MQV and MQV-Pro valves. Designed for pressure-release Clemco blast pots, it keeps the valve knob assembly secure and functional.

- OEM nut for MQV and MQV-Pro knob housing

- Secures knob assembly in place

- Fits Clemco pressure-release blast pots

- Essential for proper valve function and adjustment

- SKU: BA22762

- MPN: 22762

BA22762Clemco 22762 Nut is an OEM replacement part used in the knob housing of MQV and MQV-Pro valves. Designed for pressure-release Clemco blast pots, it keeps the valve knob assembly secure and functional.- OEM nut for MQV and MQV-Pro knob housing

- Secures knob assembly in place

- Fits Clemco pressure-release blast pots

- Essential for proper valve function and adjustment

- SKU: BA22762

- MPN: 22762

-

BA22764Clemco 22764 Metering Screw is a factory OEM replacement for MQV and MQV-Pro valves on pressure-release Clemco blast pots. Keeps abrasive flow steady and consistent during blasting.

- OEM part – fits MQV and MQV-Pro valves

- Controls abrasive media flow

- Built for Clemco pressure-release blast pots

- Restores valve performance with proper fit

- SKU: BA22764

- MPN: 22764

BA22764Clemco 22764 Metering Screw is a factory OEM replacement for MQV and MQV-Pro valves on pressure-release Clemco blast pots. Keeps abrasive flow steady and consistent during blasting.- OEM part – fits MQV and MQV-Pro valves

- Controls abrasive media flow

- Built for Clemco pressure-release blast pots

- Restores valve performance with proper fit

- SKU: BA22764

- MPN: 22764

-

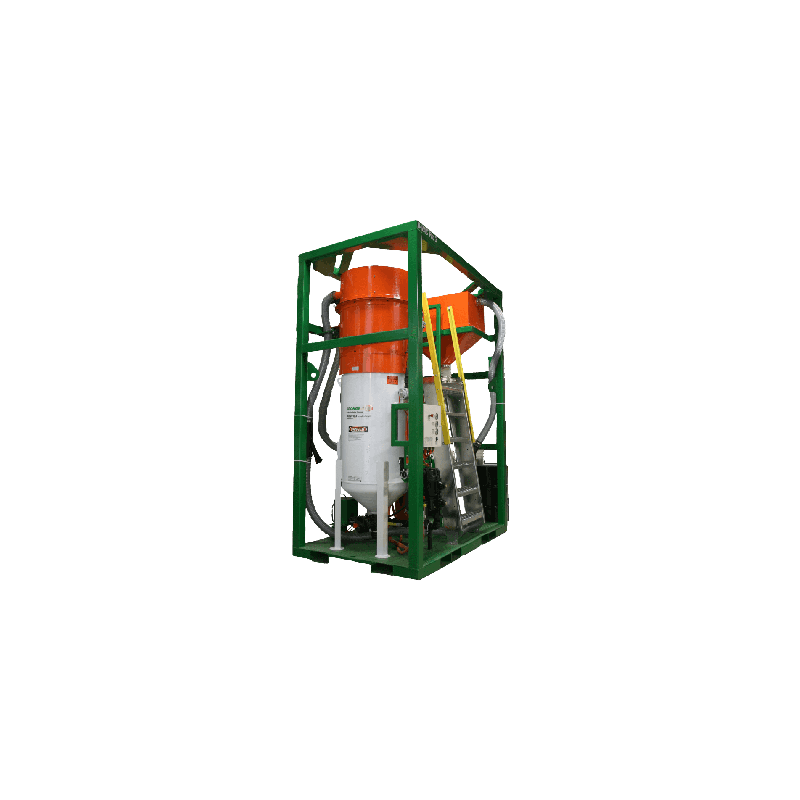

The Clemco MQV-Pro Abrasive Metering Valve offers unmatched control, efficiency, and performance for pressure-release blast machines ranging from 0.5 to 20 cubic feet. Compared to the legacy Clemco MQV valve, the MQV-Pro's compact and advanced valve design improves media flow while significantly reducing media usage and maintenance needs. Key Features:

- Precision metering for improved blasting efficiency

- Compatible with blast machines from 0.5cf to 20cf capacity

- Enhanced durability and wear resistance for longer life

- Valve design promotes smoother media flow and consistent performance with all common abrasives, mineral, slag, or steel.

- Control knob enables precise media adjustment during blasting

- Compact footprint allows for optional service ball valve installation

- Reduces abrasive consumption and system troubleshooting

- Available Sizes:

- MQV-Pro 1/2” (MPN: 31716)

- MQV-Pro 1-1/4" (MPN: 31607)

- MQV-Pro 1-1/2” (MPN: 31608)

-

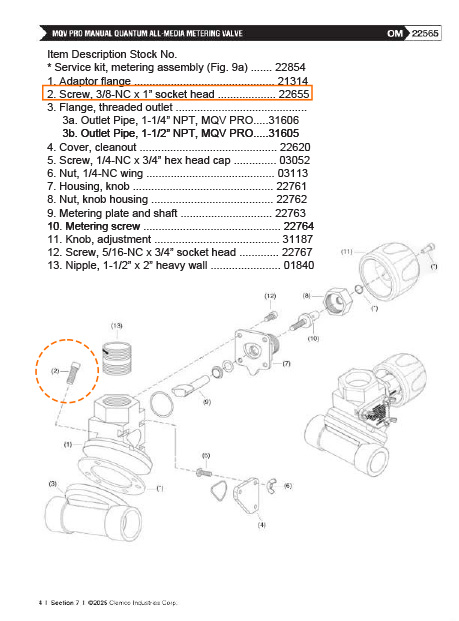

BA22655Clemco 22655 is a 3/8-NC x 1" socket head screw used in MQV, MQV-Pro, AQV, and AQV-H abrasive metering valves. It's a factory OEM replacement for securing key valve components.

- OEM socket head screw for Clemco metering valves

- Fits MQV, MQV-Pro, AQV, and AQV-H models

- 3/8-NC thread, 1" length

- Secures valve parts under pressure and vibration

- SKU: BA22655

- MPN: 22655

BA22655Clemco 22655 is a 3/8-NC x 1" socket head screw used in MQV, MQV-Pro, AQV, and AQV-H abrasive metering valves. It's a factory OEM replacement for securing key valve components.- OEM socket head screw for Clemco metering valves

- Fits MQV, MQV-Pro, AQV, and AQV-H models

- 3/8-NC thread, 1" length

- Secures valve parts under pressure and vibration

- SKU: BA22655

- MPN: 22655

-

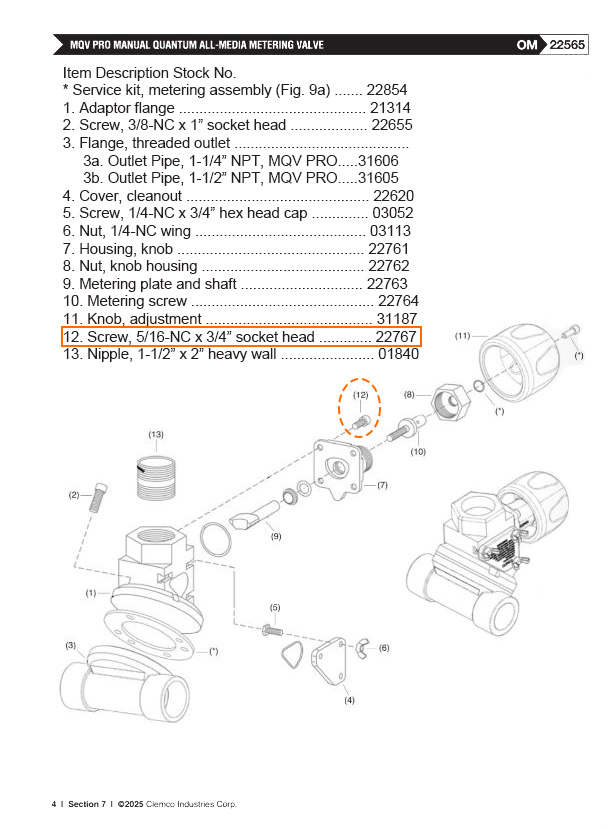

BA22767Clemco 22767 is a 5/16-NC x 3/4" socket head screw used on MQV and MQV-Pro abrasive metering valves. OEM fastener designed to secure valve components under blast conditions.

- OEM socket head screw for MQV and MQV-Pro valves

- 5/16-NC thread, 3/4" length

- Secures internal valve parts

- Used in Clemco pressure-release blast systems

- SKU: BA22767

- MPN: 22767

BA22767Clemco 22767 is a 5/16-NC x 3/4" socket head screw used on MQV and MQV-Pro abrasive metering valves. OEM fastener designed to secure valve components under blast conditions.- OEM socket head screw for MQV and MQV-Pro valves

- 5/16-NC thread, 3/4" length

- Secures internal valve parts

- Used in Clemco pressure-release blast systems

- SKU: BA22767

- MPN: 22767

-

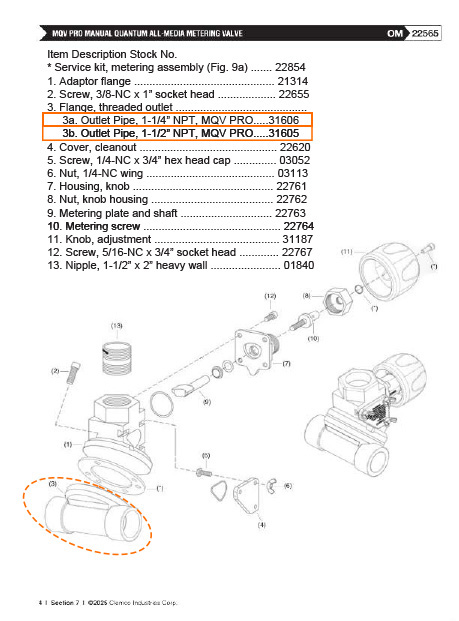

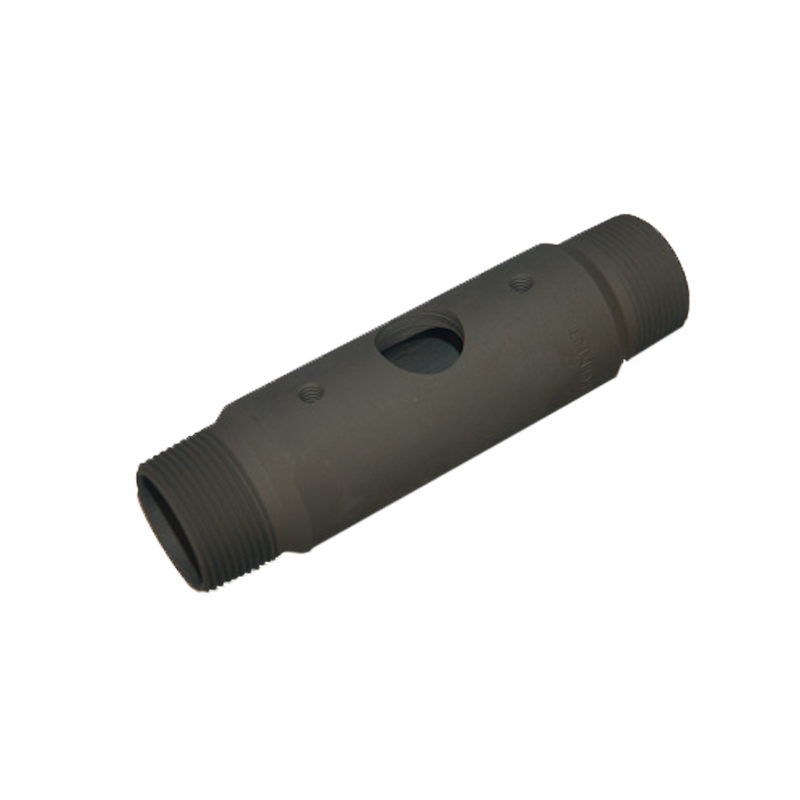

Clemco MQV-Pro Outlet Pipes are OEM replacement parts designed to fit the MQV-Pro metering valve only. Available in 1-1/4", and 1-1/2" sizes, each pipe ensures a proper abrasive flow path in pressure-release Clemco blast systems.

- OEM replacement outlet pipe for MQV-Pro metering valves only

- Used on Clemco pressure-release blast pots

- Restores abrasive flow from valve to hose

- MPNs:

- 31606 (1-1/4")

- 31605 (1-1/2")

-

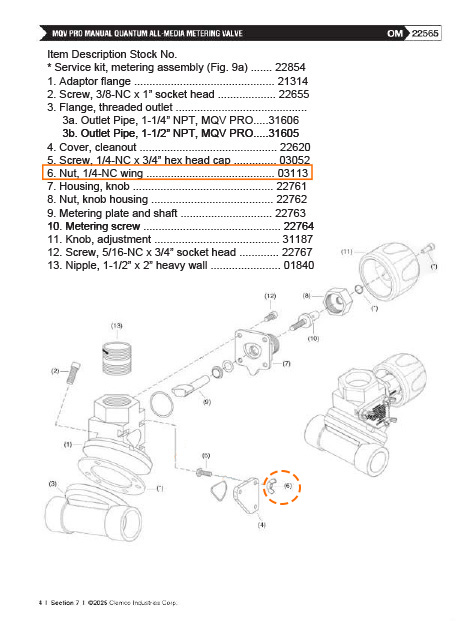

GVFSV1011Clemco 03113 Wing Nut is an OEM replacement part used to secure components in multiple Clemco metering valves and the BNP160 cabinet.

- OEM wing nut for Clemco metering valves and cabinets

- Fits Sentinel, MQV, MQV-Pro, and FSV valves

- Also used in BNP160 Tumble Blast Cabinet

- Secures valve components during operation

- SKU: BA03113

- MPN: 03113

GVFSV1011Clemco 03113 Wing Nut is an OEM replacement part used to secure components in multiple Clemco metering valves and the BNP160 cabinet.- OEM wing nut for Clemco metering valves and cabinets

- Fits Sentinel, MQV, MQV-Pro, and FSV valves

- Also used in BNP160 Tumble Blast Cabinet

- Secures valve components during operation

- SKU: BA03113

- MPN: 03113

-

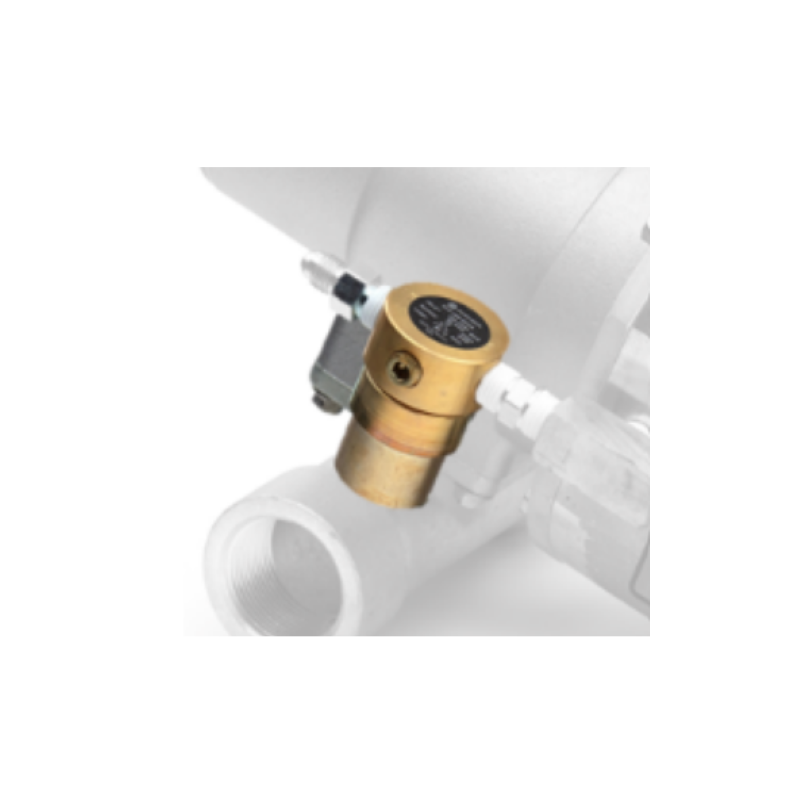

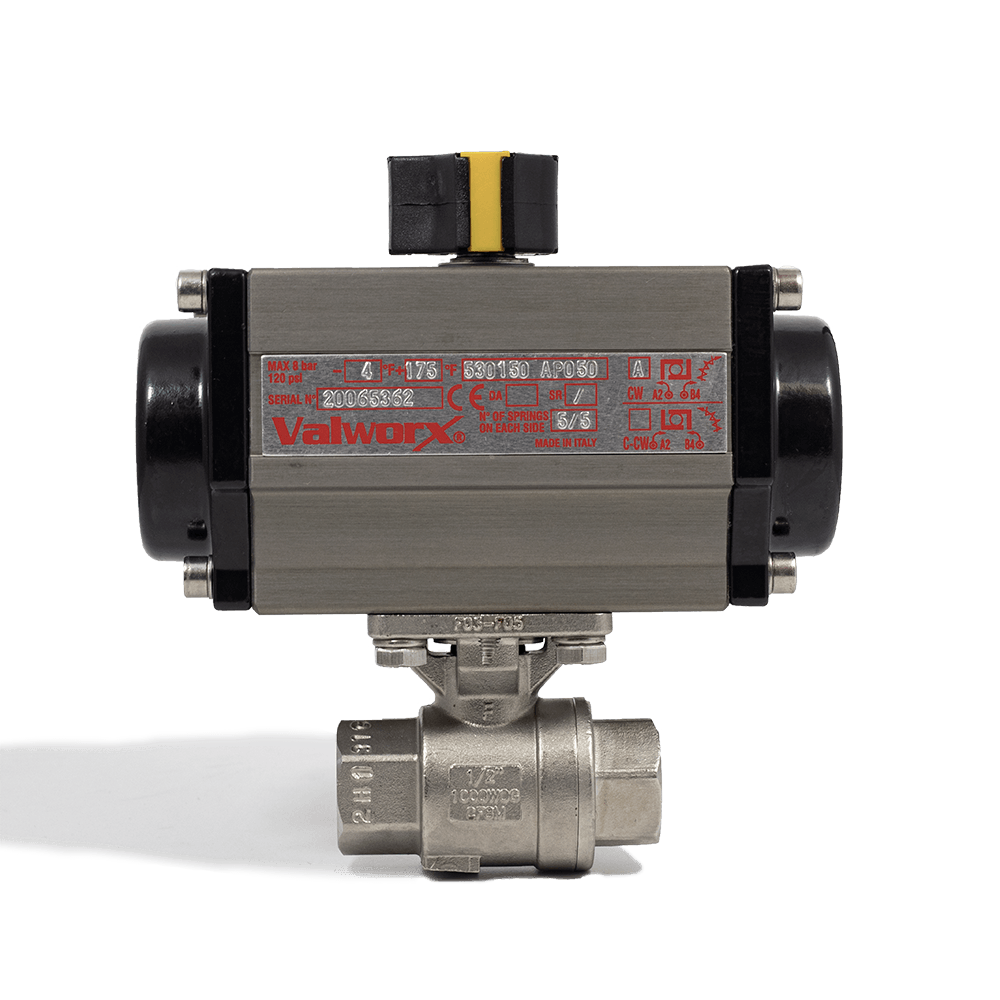

GV2410320BVThe GV2410320BV Union End Ball Valve with Tri-Clover Adapter Clamp Assembly is designed for improved serviceability of abrasive metering valves in blast pot setups. Ideal for new installations, it allows technicians to remove the valve for maintenance without needing to empty abrasive material from the pot. Ensure 9 inches of clearance before ordering.

- Provides easy metering valve removal without pot emptying

- Installs between the blast pot and abrasive metering valve

- Recommended for new installations, but can also be retrofitted to existing pots

- Adds 9 inches of height—verify clearance before ordering

- Includes: Union End Ball Valve (SKU GV2408907, MPN 2408-907)

- Includes: Tri-Clover Adapter Clamp Assembly (SKU GV2410320)

- Assembly SKU: GV2410320BV

GV2410320BVThe GV2410320BV Union End Ball Valve with Tri-Clover Adapter Clamp Assembly is designed for improved serviceability of abrasive metering valves in blast pot setups. Ideal for new installations, it allows technicians to remove the valve for maintenance without needing to empty abrasive material from the pot. Ensure 9 inches of clearance before ordering.- Provides easy metering valve removal without pot emptying

- Installs between the blast pot and abrasive metering valve

- Recommended for new installations, but can also be retrofitted to existing pots

- Adds 9 inches of height—verify clearance before ordering

- Includes: Union End Ball Valve (SKU GV2408907, MPN 2408-907)

- Includes: Tri-Clover Adapter Clamp Assembly (SKU GV2410320)

- Assembly SKU: GV2410320BV

-

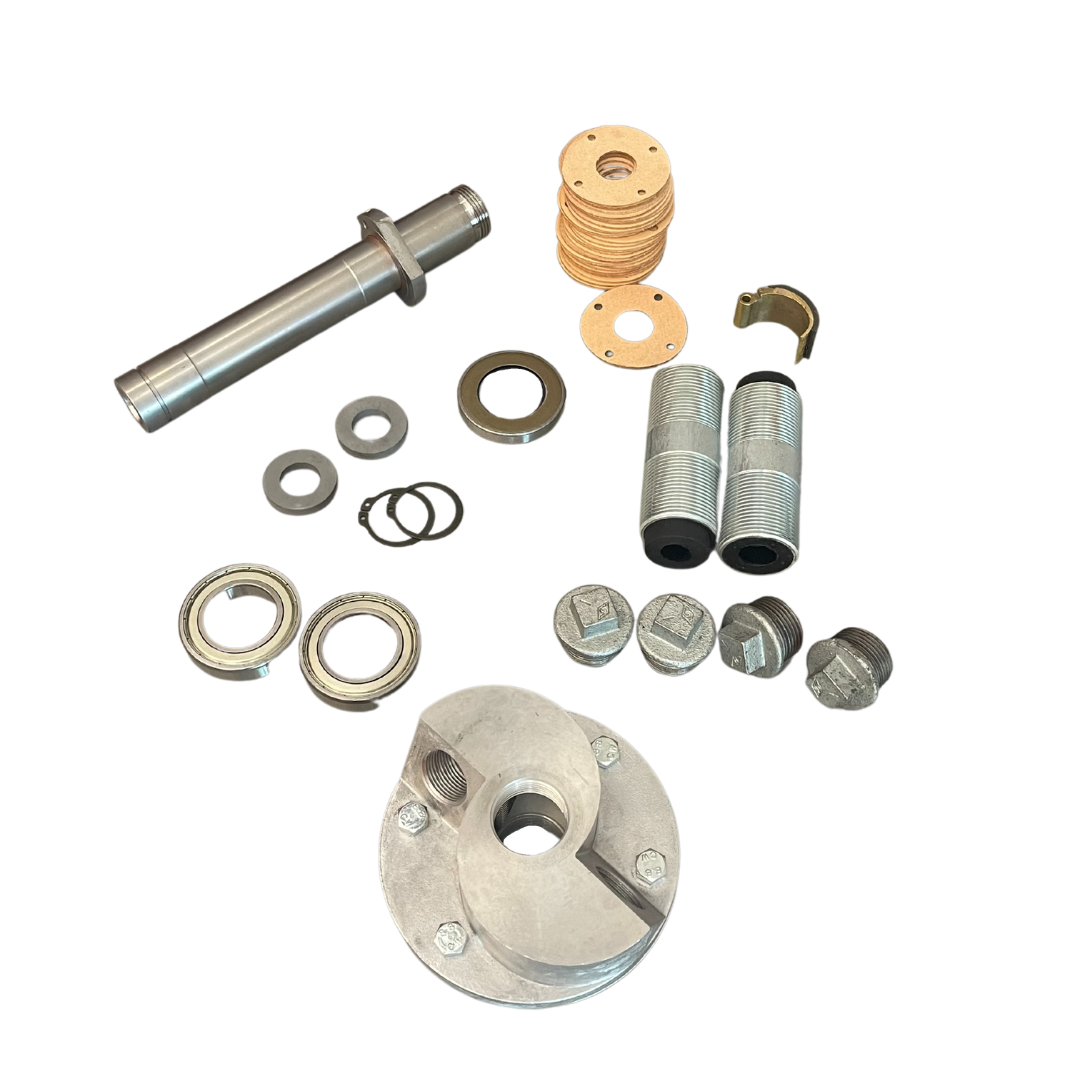

DM21336

The Clemco Millennium Inlet/Outlet Valve Assembly (aka Clemco Combo Valve / MPN: 21336) is a dual-function remote control valve designed for contractor-style blast machines. It combines inlet and outlet functions, features a built-in exhaust muffler for noise reduction, and provides rapid pressurization and depressurization for efficient operation. This fail-safe system ensures safety and reliability, making it ideal for demanding abrasive blasting applications.

Key Features:

- 1-1/2-inch inlet port for unrestricted air flow.

- Built-in exhaust muffler minimizes depressurization noise.

- Internal air connection eliminates external hoses for reduced wear and maintenance.

- Fail-safe design halts air and abrasive flow if air supply is interrupted or remote handle is released.

- Compatible with remote control handles for easy start/stop operation.

- Easy maintenance in the field with standard tools.

DM21336The Clemco Millennium Inlet/Outlet Valve Assembly (aka Clemco Combo Valve / MPN: 21336) is a dual-function remote control valve designed for contractor-style blast machines. It combines inlet and outlet functions, features a built-in exhaust muffler for noise reduction, and provides rapid pressurization and depressurization for efficient operation. This fail-safe system ensures safety and reliability, making it ideal for demanding abrasive blasting applications.

Key Features:

- 1-1/2-inch inlet port for unrestricted air flow.

- Built-in exhaust muffler minimizes depressurization noise.

- Internal air connection eliminates external hoses for reduced wear and maintenance.

- Fail-safe design halts air and abrasive flow if air supply is interrupted or remote handle is released.

- Compatible with remote control handles for easy start/stop operation.

- Easy maintenance in the field with standard tools.

My Account

My Account

Abrasive Metering Valves

Abrasive Metering Valves Abrasive Metering Valve Parts

Abrasive Metering Valve Parts Air Control Valves & Related

Air Control Valves & Related Deadman / Control Systems

Deadman / Control Systems General Repair Parts for Blast Pots

General Repair Parts for Blast Pots Internal Pipe (ID) System Components

Internal Pipe (ID) System Components MistBlaster Specific Parts

MistBlaster Specific Parts Sponge Blast Equipment Parts

Sponge Blast Equipment Parts Vacuum Blaster Workheads, Parts & Related

Vacuum Blaster Workheads, Parts & Related VertiDrive Specific Parts

VertiDrive Specific Parts