RULES OF THUMB FOR THE APPLICATION OF NON-SLIP GRANULES INTO COATINGS

Finishing our refresher on non-slip coatings, Graeme shares his experience of having personally been involved in the application of non-slip granules hundreds of times over the course of his career. Just in case you missed Video #1 here is the link.

When To Spread The Grains

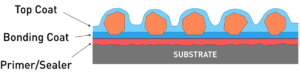

- Our first principle is we need the grain to sit in wet coating

- We always recommend granules go into the second coating (seal the surface first)

- Always apply a third coat to encapsulate and lock in the grains

My Account

My Account