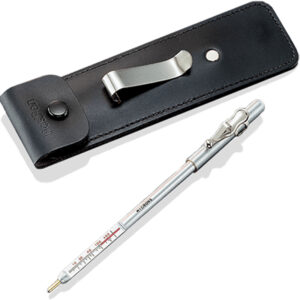

DeFelsko® Powder Comb

Sku: P-INDPC

Designed to optimize coating processes, the DeFelsko® Powder Combs are indispensable for professionals aiming for perfection in powder coating applications. These precision gauges are capable of measuring uncured powder thickness on an array of substrates, facilitating a reliable assessment to achieve ideal cured film thickness from the outset. This method significantly reduces the likelihood of stripping and re-coating, thereby preserving adhesion quality and coating integrity. The Powder Combs are meticulously crafted to maintain accuracy, featuring broad stand-offs that ensure the gauge remains perpendicular during measurements. With a construction tolerance of ±5 microns or ±0.0002 inches, these tools exemplify precision manufacturing. The rugged aluminum build enhances gauge life and ensures static control, while the pocket-size design and included protective leather pouch enhance its portability and ease of use.- Engineered for precise measurement with a tolerance of ±5 microns or ±0.0002 inches.

- Aluminum construction and broad stand-offs for durability and accurate positioning.

- Simple operation process for quick and efficient thickness assessments.

- Supports a range of substrates, enhancing versatility in quality control processes.

My Account

My Account