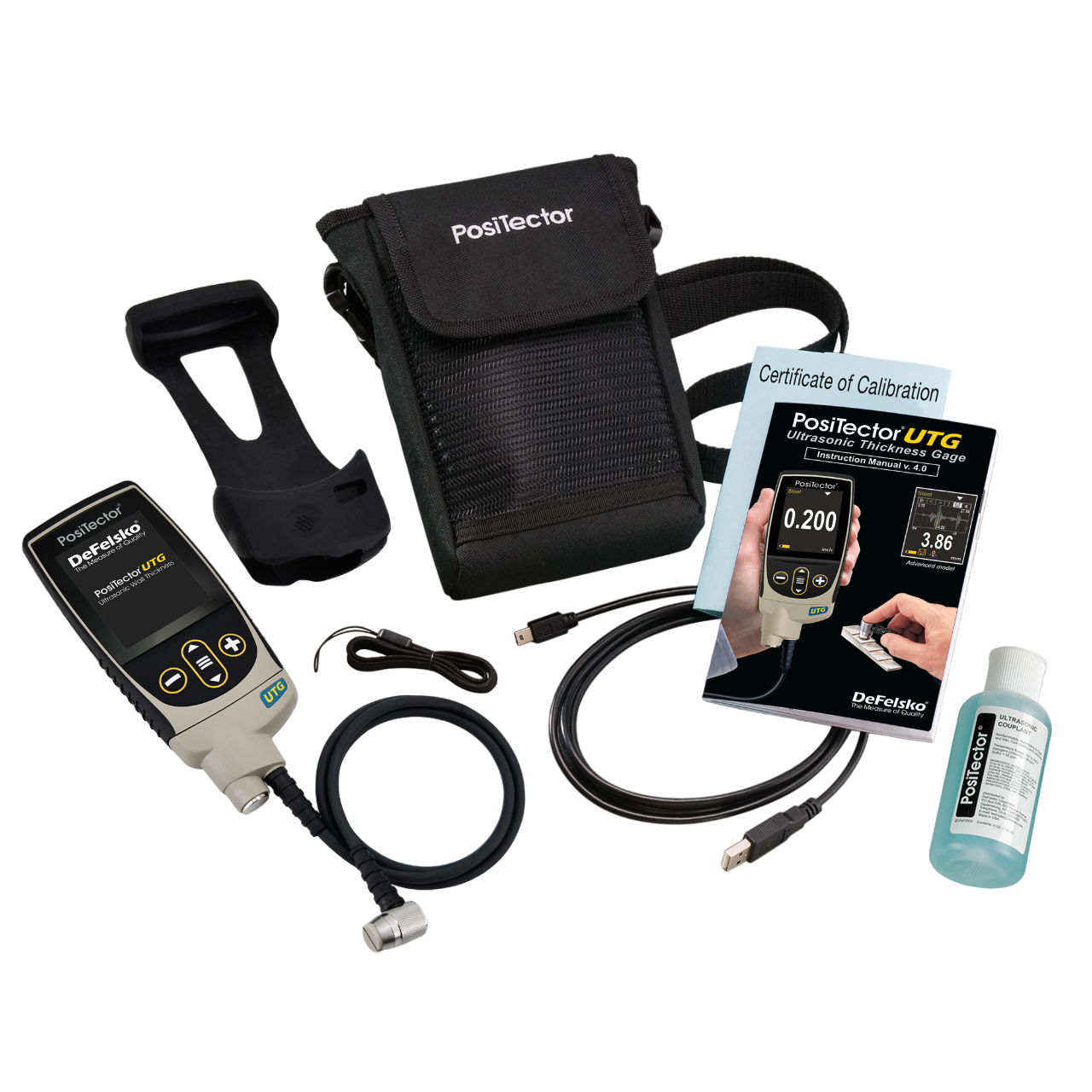

DeFelsko® PosiTector® UTG Ultrasonic Thickness Gauge

Sku: P-INDUTG

The DeFelsko® PosiTector® UTG Ultrasonic Thickness Gauge stands at the forefront of thickness measurement technology, offering unparalleled precision and ease of use for professionals in a wide range of industries. Whether monitoring the integrity of tanks and pipes or evaluating the effects of corrosion on structural materials, the PosiTector® UTG delivers reliable, accurate measurements even in the most challenging conditions where access to both sides of the substrate is not easily available. One version of this instrument distinguishes itself with the ability to measure the metal thickness of painted structures without the need to remove the coating, thanks to its advanced Multiple Echo (UTG M) Thru-Paint technology. Pre-programmed with velocities for common materials, the PosiTector® UTG allows for quick setup and initiation of testing procedures. The Min Scan mode is particularly useful for conducting swift inspections over large areas, recording minimum and maximum thicknesses to identify potential weaknesses or failures. Durability is a hallmark of the PosiTector® UTG, featuring a rugged, weatherproof, and dustproof design that's ideal for both field and shop applications. The device's two-year warranty, shock-absorbing holster, and braided stainless steel cable (on the PosiTector UTG CX model) underscore its readiness for demanding applications. Accuracy is ensured with precision ultrasonic transducers and built-in temperature compensation, while conformity to ASTM E797 and other standards guarantees compliance with international measurement requirements. My Account

My Account