Achieving Proper Profile Angularity: Boosting Adhesion in Blasting Projects

Introduction

In the world of industrial blasting and coatings, achieving the correct surface profile is crucial for the longevity and durability of your coatings. Lately, we’ve seen a growing demand for specifications requiring an angular profile, and for good reason—profile angularity plays a significant role in improving adhesion.

Why Angularity Improves Adhesion

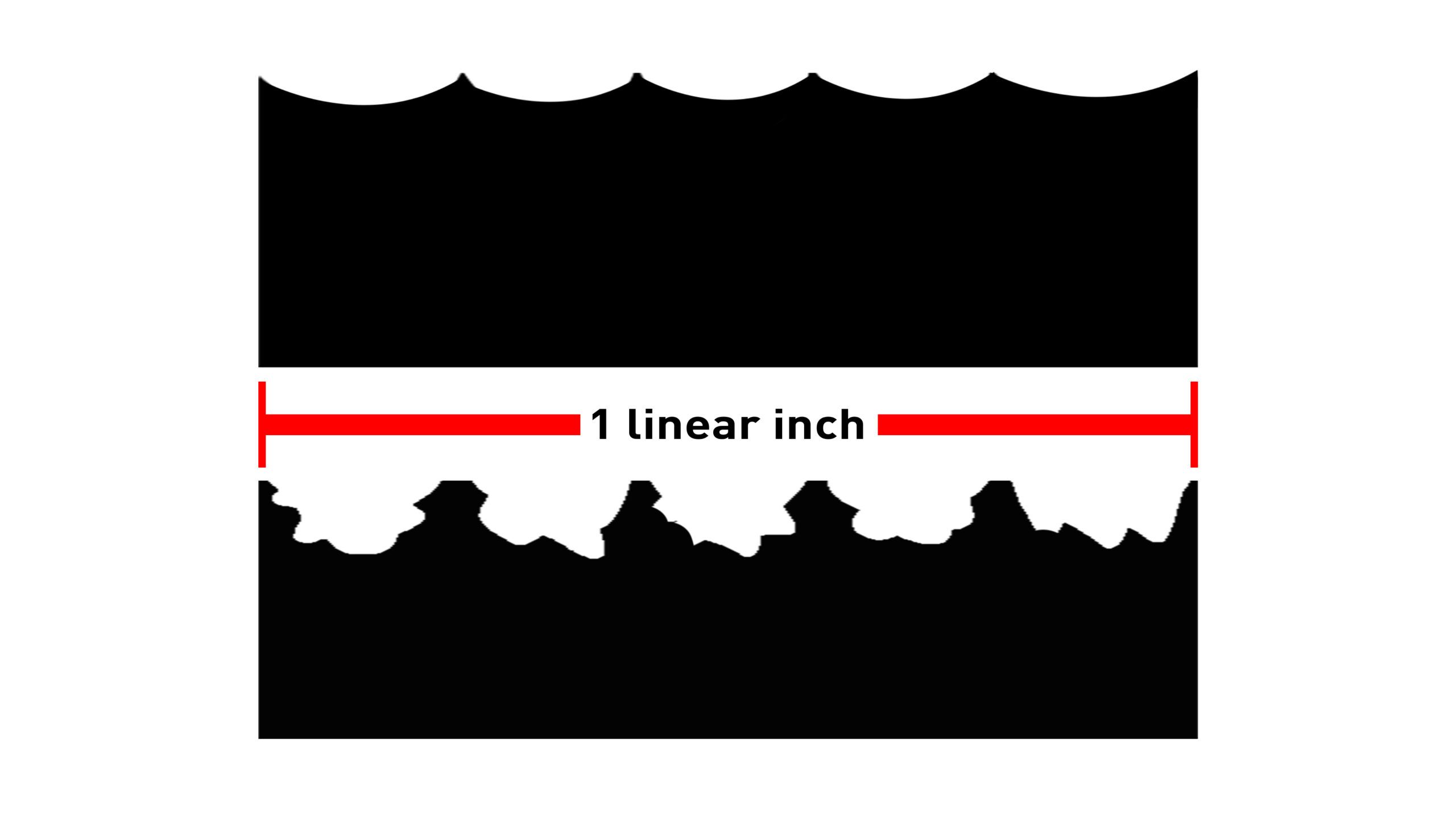

The science behind profile angularity is straightforward yet powerful. Coatings adhere to steel surfaces through two main types of adhesion: chemical and mechanical. Chemical adhesion involves the bonding of coating molecules with the steel’s atoms, while mechanical adhesion is created by the physical anchoring of the coating to the roughness of the substrate. The more peaks and valleys you have on the surface, the more connection points are available, resulting in stronger adhesion.

Why Recycling Abrasives Reduces Angularity

While angular profiles are ideal for adhesion, it’s important to note that the abrasive you use significantly influences the profile’s shape. Angular abrasives, like fresh steel grit, are preferred because they create the desired rough surface. However, if you’re recycling abrasives, be aware that their angularity will diminish with each use.

As abrasives are reused, they tend to round off due to the repeated impact with the steel surface. This rounding off reduces the angularity, which in turn decreases the effectiveness of the mechanical adhesion. In some cases, abrasives can even become so rounded that they start to hammer contaminants into the surface rather than removing them, further compromising the coating’s bond.

For those using recycled steel grit, it’s crucial to regularly introduce fresh abrasive into the mix. This practice helps maintain the angularity necessary for achieving a strong profile and ensures consistent adhesion.

Three Simple Steps to Ensure Proper Angularity

- Choose the Right Abrasive: Select an abrasive that is sub-angular for the best results. Extremely angular abrasives can break off and embed themselves in the substrate, weakening adhesion. Aim for a balance between angularity and durability. Shop our full line of abrasives here.

- Maintain Abrasive Quality: If you’re recycling abrasives, make sure to add new abrasive regularly to counteract the natural rounding that occurs over time. This will help maintain the angular profile and ensure consistent surface preparation.

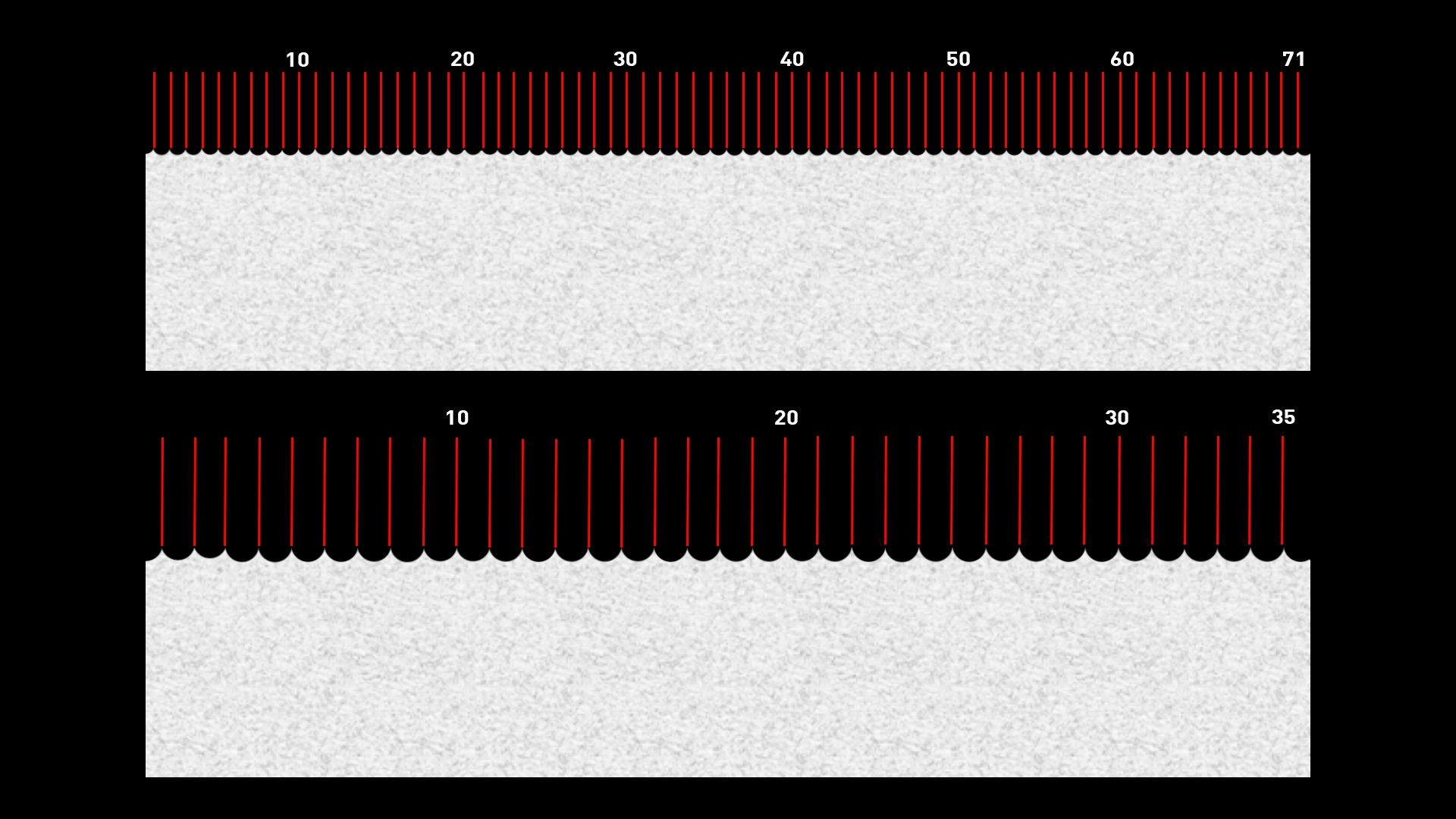

- Measure Surface Angularity: Since there isn’t a recognized industry standard for measuring angularity, create an in-house standard based on peak count and profile height. Tools like an RTR-P Reader can help you measure both peak count and profile height to ensure you’re achieving the desired angularity.

Conclusion

Achieving the correct surface profile angularity is essential for maximizing the adhesion of coatings to steel surfaces. By selecting the right abrasive, maintaining its quality, and accurately measuring the profile, you can ensure that your blasting projects meet the highest standards of adhesion and durability.

If you have any questions about achieving proper profile angularity or need advice on your next blasting project, feel free to contact us. We’re here to help you achieve the best possible results.

My Account

My Account