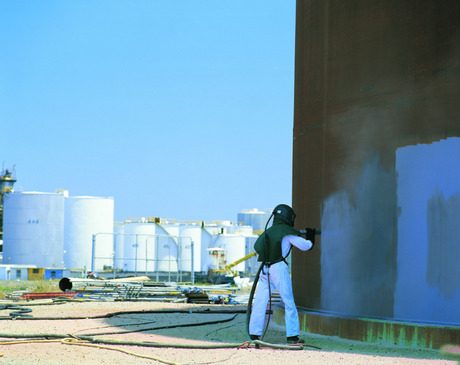

Access around fuel tanks is often a challenge because of the distances involved. Typically, the hoses are run around the outside of the tank. This can result in pressure losses when blasting and also when painting.

Where a tank has two or more access points, either move your blast rig once the first half is completed or set-up a second rig. This not only improves performance, but it eliminates the need to run an extra hose to the other side of the tank.

Plan ahead! Before you start a new project, take time to plan your equipment placement. This helps to ensure a more efficient and productive project outcome.

My Account

My Account