FINDING THOSE PRESSURE LEAKS

CASE STUDY PROBLEM: Recently a customer invited us onto their jobsite in hopes we might help increase their productivity. We love this challenge, and the first thing we always take a look at after taking a quick walk of the entire system is the pressure at the nozzle. The reason we prioritize pressure is due to this foundational truth:

For every 1 PSI lost, you lose 1.5% productivity.

The inverse is also true.

For every 1 PSI you gain – you’ll increase your productivity 1.5%.

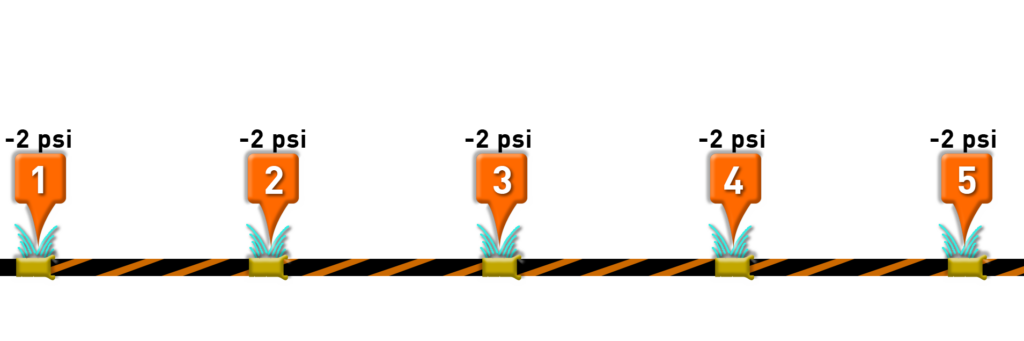

On this particular jobsite they were running long lengths of hose – just over 250 feet. They had 200 feet of 1-1/2” hose, then had a 50ft 1-1/4” whip hose, which all looked ok. So we took pressure readings along the system, at the nozzle and just after the blast pot and discovered they were losing roughly 10 psi over this long run.

10 psi loss = 15% Productivity loss.

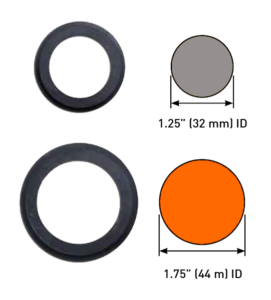

So we studied this situation and decided to test if the couplings were causing us any pressure loss… The reason is, that standard couplings have a 1-1/4” internal diameter, which would be creating a restriction every 50ft along the hose.

My Account

My Account