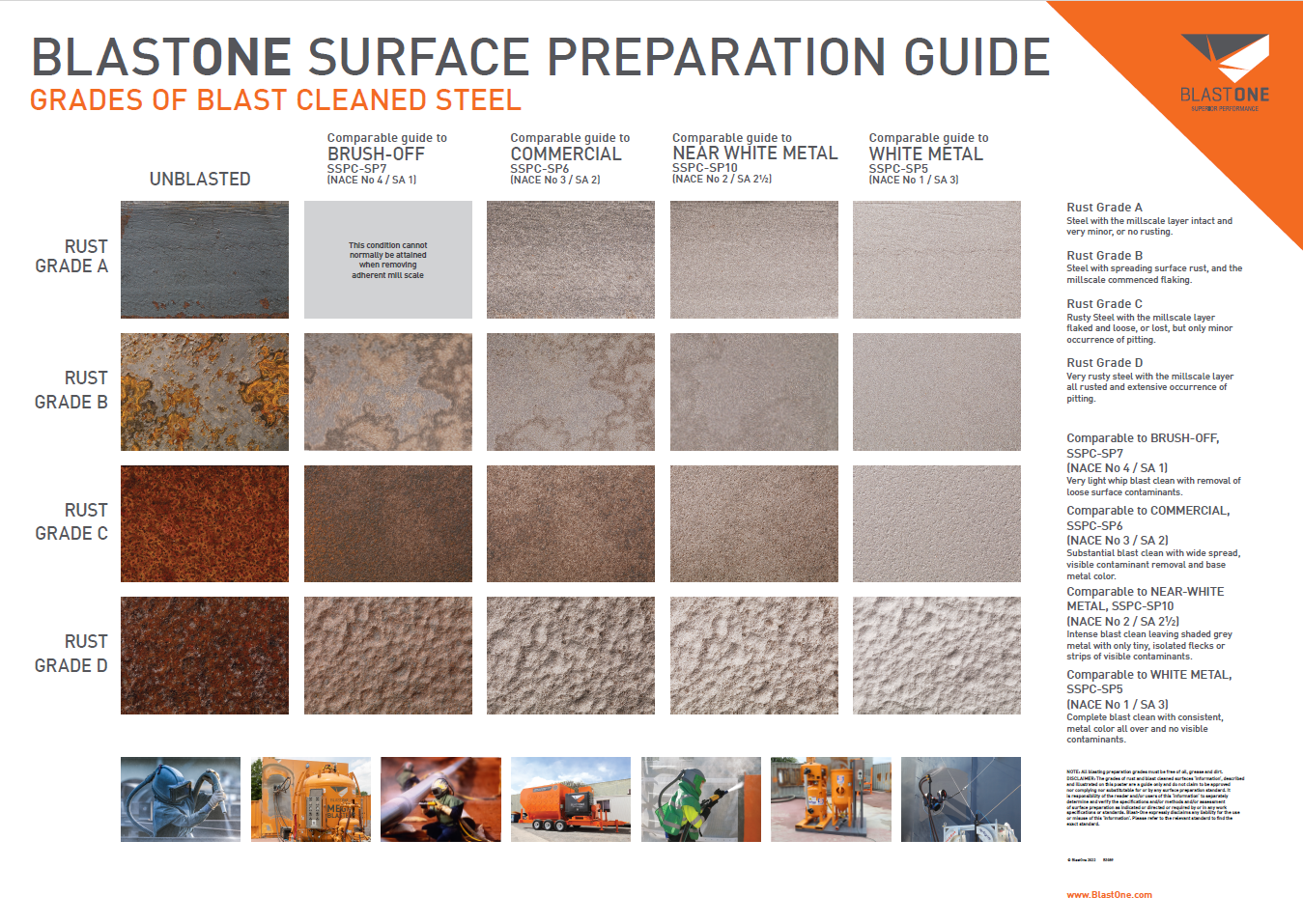

When assessing the degree of removal of rust, mill scale, and other visual contaminants from steel surfaces, it’s crucial to understand the different grades of rust and the corresponding blast cleaning standards.

Important Note: Surface cleanliness is not a measure of surface profile – see the following pages for notes on surface profile.

DISCLAIMER: The grades of rust and blast cleaned surfaces ‘information’, described and illustrated on these pages are a guide only and do not claim to be approved nor complying nor substitutable for or by any surface preparation standard. It is responsibility of the reader and/or users of this ‘information’ to separately determine and verify the specifications and/or methods and/or assessment of surface preparation as indicated or directed or required by or in any work specifications or standards. Blast-One™ expressly disclaims any liability for the use or misuse of this ‘information’.

My Account

My Account