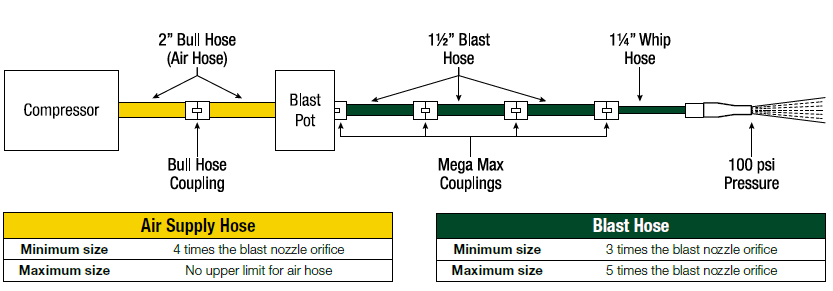

Use Mega Max couplings to achieve an unrestricted airflow.

All blast hoses with an ID greater than 1.25″ (32mm) should have MegaMax couplings fitted to reduce air flow restrictions. The advantage in using large bore hose fittings is the reduction of gasket and coupling wear. Mega Max couplings have larger coupling gaskets with larger bores.

A few things to keep in mind:

A rule of thumb is any nozzle 1/2″ or above – use Mega Max couplings. In order to have free flow air, you need two inch bull hoses. In this case, you would require a 400+ cfm compressor for 100psi at the nozzle. An unrestricted air flow produces less pressure loss, with increased performance.

Also, to make sure you have the right equipment, go ahead and look at the compressor CFM. Lastly, note that mega couplings are necessary for large blast pots.

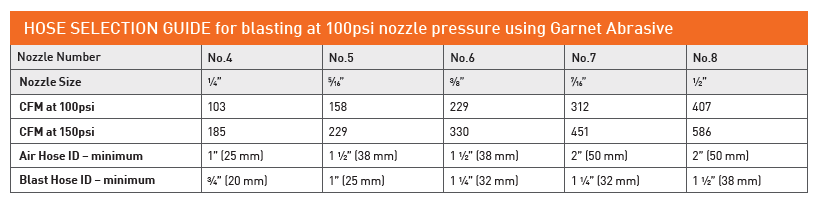

See the hose selection guide below (Read our full catalog):

My Account

My Account