The challenge of maintaining business operations while conducting extensive renovations is considerable, especially in the context of surface preparation and coating in bustling environments. This was the scenario faced during the comprehensive restoration of a 161-space parking facility in Massachusetts. The garage, an essential part of a multi-use complex hosting banks, law firms, and a variety of businesses, required a delicate approach to avoid disrupting the daily flow of people and adjacent commercial activities.

APC Services of New England (APCNE) was at the helm of this intricate project, understanding that the key to its success lay in selecting an optimal method for surface preparation. The proximity of the garage to buildings with roof ventilators and intakes compounded the necessity for a dust-free solution to safeguard both environmental and worker health.

The task was further complicated by the need to operate amidst a diverse array of other tradespeople involved in the garage’s refurbishment. From welders working on the roof decking to masonry and electrical specialists, the workspace was a hive of activity requiring meticulous coordination and minimal dust interference.

As highlighted in CoatingsPro Magazine, APCNE’s Project Manager and Estimator, Garrett King said this about the project:

“The customer was so happy and impressed with the color and generally how bright the garage looked.”

Garret continues later in the article, “Owners who invest in their buildings, especially during (unplanned breaks), show their tenants that they’re not only investing in their infrastructure, but also in the tenants themselves.”

Challenges with the Existing Structure

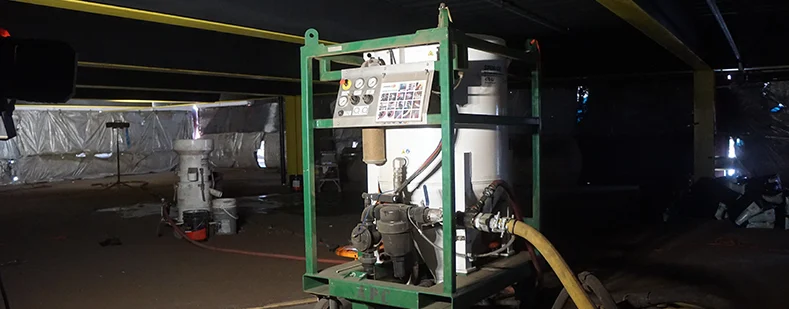

The primary goal was to revitalize the garage’s roof decking and structural steel, which upon initial inspection, revealed a surface plagued with both intact and deteriorating coatings, alongside varying degrees of rust. Sponge Media blasting emerged as the chosen method for eradicating corrosion and peeling paint, prepping the galvanized roof decking, steel beams, and other components for the application of a new coating system, including a Tnemec modified aromatic polyurethane primer and a waterborne acrylic mastic topcoat.

Over 100,000 square feet of steel surface was meticulously prepared with Silver 30 Sponge Media™, achieving an SSPC SP-6 – Commercial Blast cleanliness with a 3-mil profile, proving Sponge Media’s efficacy in achieving high standards of surface preparation.

The Advantages of Sponge Media in Complex Environments

Sponge Media presented a cost-effective and efficient alternative to coal slag, without the need for extensive dust suppression measures or risk of damage from rebound, which are common concerns with traditional abrasive materials. The versatility of Sponge Media was especially beneficial given the project’s winter timeline, unaffected by the freezing temperatures that would have rendered vapor blasting impractical.

This project was not APCNE’s first foray into large-scale Sponge Blasting, having previously undertaken a parking garage fire restoration in 2018, further solidifying their expertise and confidence in Sponge Media’s benefits for challenging restoration projects.

ADDITIONAL SPONGE-JET CASE STUDIES

Contact BlastOne

We love to talk to customers and help them make the best decisions when purchasing equipment.

You can reach us via our Live Chat, Email, Phone, and Online Form.

My Account

My Account