Your Jobsite’s Biggest Problems Were Invisible…until now.

It’s 7:00 AM. The crew clocks in, hoses are hooked up, the compressor hums to life.

By 10:00 AM, everything looks fine. But what are the small issues you don’t see?

One hose is running at 90 PSI—15% productivity loss. Another crew had a 45-minute delay resetting the pot. Nobody logged it. Nobody noticed.

By 3:30 PM, the site’s behind schedule. Abrasive usage is higher than expected.

You wrap up the day thinking, “We’ll make it up tomorrow!”

Tomorrow, however: Rinse and Repeat.

Weeks later, you’re significantly behind and overbudget? Why?

Your blast pot knows why.

IntelliBlast gives your blast pot a voice…and your jobsite visibility.

The 3 key metrics that determine blasting success are:

• Blasting Pressure

• Abrasive Consumption

Without knowing these key metrics you’re guessing… and guessing is expensive!

REAL-TIME JOBSITE INTEL

Less than $5/hr per blaster

REQUEST PRICING OR A LIVE DEMONSTRATION

Take the first step to exposing your small issues before they become major problems.

Everett Ship Repair

By leveraging best practices and blast pot intel from IntelliBlast, two consecutive projects had a overall cost reduction of 47%

Cenovus Tank #771

By leveraging IntelliBlast data and BlastOne insights, total blast days to complete the project dropped from 11 to 5 days.

IntelliBlast™ Prevents Small Issues From Becoming Major Issues

IntelliBlast™ is the only real-time monitoring system built for abrasive blasting. It transforms every blast pot into a productivity management center – tracking nozzle pressure, time-on-tools, and idle time. With live dashboards and alerts, it empowers crews to catch issues early, prevent downtime, avoid rework, and optimize performance.

Designed to track and improve two of the biggest drivers of profit:

- Time on tools – know exactly how long crews are actually blasting.

- Blasting pressure – spot drops before they quietly erode performance.

IntelliBlast eliminates guesswork from abrasive blasting so you can finish jobs faster, waste less abrasive, and hit your margins with confidence.

01

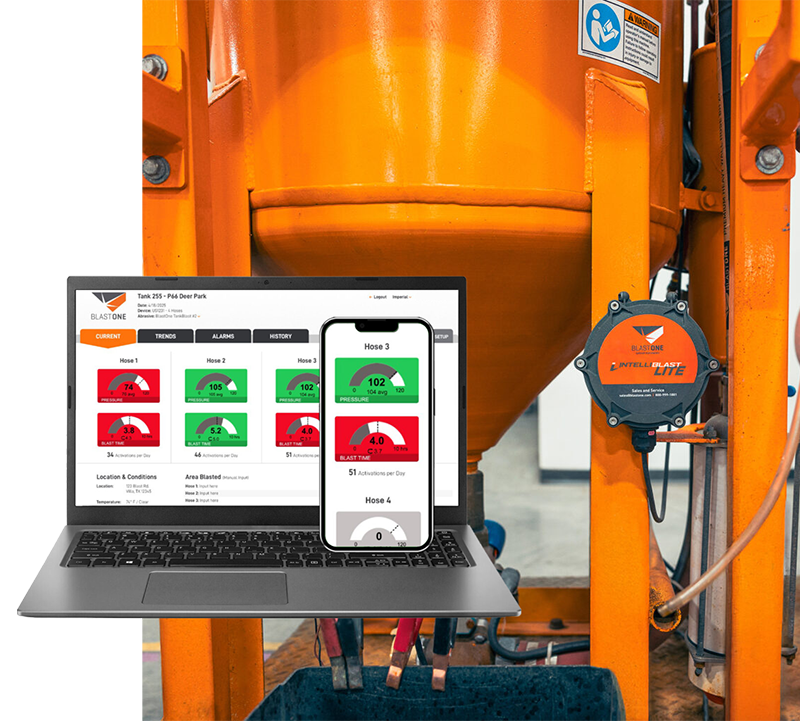

Ensure Optimized Performance

See what everyone misses

IntelliBlast™ Lite gives you live crew data so you can keep blasting at full power to avoid waste.

- Monitor daily blast time, pressure, and activation counts.

- Know your TRUE ‘time on tools’.

- Reduce downtime and rework.

- Optimize every hour of blasting operations.

02

Faster Problem Detection

Prevent small problems from becoming jobsite disasters

IntelliBlast™ Lite catches performance issues early – so crews stay productive and small problems never snowball.

- Instant alerts when pressure drops or blasting stops

- Prevent costly delays from unnoticed inefficiencies

- Maintain consistent output across shifts

03

Remote Real-Time Insights

Take control anywhere

Whether you’re on-site or off, IntelliBlast™ Lite keeps you fully connected to every vital sign of your blasting operation.

- Access vital metrics remotely from your smart device.

- React in real-time to keep jobs on track and budgets intact.

- Monitor crews and equipment across multiple sites

INTRODUCING INTELLIBLAST™ LITE

Smart, real-time monitoring system for your blast pot.

- Track blasting pressure and ‘time-on-tools’

- Environmental sensing

- GPS tracking

- Instant alerts

- Cloud-based data access

- Retrofit to your existing blast pot

- Multi-outlet capability

Frequently Asked Questions

Is training included with IntelliBlast Lite?

Absolutely! Full training is included to ensure your team knows how to use the system effectively from day one.

Can I monitor multiple units or job sites at once?

Yes. The dashboard supports multiple units and provides a centralized view of all active IntelliBlast Lite devices.Does it provide real-time alerts?

Yes. IntelliBlast Lite can send instant alerts via email or SMS for events like pressure drops or idle time – depending on the platform configuration.Can IntelliBlast Lite be installed on my existing blast pot?

Yes. IntelliBlast Lite is retrofit-ready and installs on most pressure-hold blast pots with electric deadman systems and a 12V DC power supply.Do I need a sim card and WIFI?

The IntelliBlast Lite sensor comes with a pre-installed SIM card. To operate the sensor, the blast machine must be within WiFi range.How do I access the data?

All data is stored securely in the cloud and can be accessed via an online dashboard.Can I export the data for reports or analysis?

Yes. Data can be exported from the dashboard in standard formats for reporting, project tracking, or estimating.Is it rugged enough for harsh environments?

Absolutely. The compact sensor unit is built to withstand dust, vibration, moisture, and physical impact on tough jobsites.

Contact BlastOne

We love to talk to customers and help them make the best decisions when purchasing Air preparation and drying equipment.

You can reach us via our Live Chat, Email, Phone, and Online Form.

My Account

My Account