PRECISION PLURAL COMPONENT MIXING FOR INDUSTRIAL COATINGS

Optimize your coating process with BlastOne’s proven plural component mixing technology—trusted worldwide for accuracy, reliability, and reduced waste.

My Account

My Account

Catalog | Locations | Bulk Order | Quote List

Optimize your coating process with BlastOne’s proven plural component mixing technology—trusted worldwide for accuracy, reliability, and reduced waste.

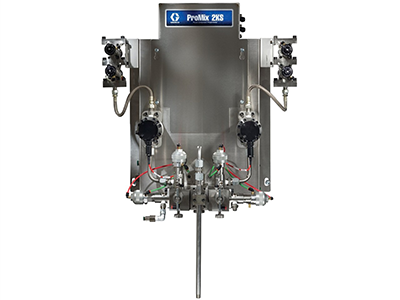

The ProMix Series delivers exceptional precision in plural-component mixing for liquid coatings. Designed for industries demanding repeatable quality and reduced material costs, these systems handle a wide range of chemistries including solventborne, waterborne, and acid-catalyzed coatings. Each model—ProMix 2KE, ProMix 2KS, and ProMix V—offers scalable options to meet varying levels of automation, color complexity, and process control.

Ideal for manual mixing and dosing, the ProMix 2KE ensures accurate ratio control with compact design and low waste.

A scalable, upgradeable system designed for high-accuracy dosing and automated color management.

The next generation of manual plural component mixing, the ProMix V adds flexibility and digital intelligence.

KEY FEATURES

KEY FEATURES

KEY FEATURES

BENEFITS

Compact, easy installation; up to three color capability; proven reliability.

BENEFITS

Reduced material waste, faster color changeovers, consistent coating quality, and complete traceability for compliance needs.

BENEFITS

Enhanced process visibility, remote adjustments, and simplified maintenance with lower total cost of ownership.

Provides wireless system access for real-time monitoring, remote recipe management, and data logging—reducing downtime and simplifying compliance reporting.

Contains solvents safely, improving operator safety and cleaning consistency while reducing environmental impact.

Engineered for acid-cured coatings, ensures precise low-volume catalyst dosing (1–10%) to prevent finish failures.

Registration is required to create a Quote.

Click Here to Login or Register.