DUST COLLECTION FOR BLASTING OPERATIONS

Abrasive blasting generates highly aggressive dust that requires specialized collection—not general-purpose units designed for welding or woodworking. BlastOne Dust Collection Systems are engineered specifically for abrasive blasting environments. OSHA recommends maintaining a minimum airflow of 50 ft/min past the operator to ensure visibility, safety, and compliance. By removing dust effectively, extending filter life, and reducing downtime, our systems provide the reliability and long-term durability needed in high-demand blast rooms.

KEY FEATURES

Engineered for Performance and Durability

The BlastOne Dust Collector has been designed and built from the “ground up” as a Blasting Ventilation Dust Collector. There are many unique features in BlastOne Dust Collectors that ensure a low long term operational cost.

Rounded Top

The BlastOne dust collector features a distinctive rounded top, a design specifically engineered to prevent the accumulation of rainwater. This innovative feature significantly reduces the potential for rusting, ensuring enhanced durability and longevity of the collector.

Sliding Filter Cartridge Design

The BlastOne dust collector is equipped with a convenient slide- out filter changing feature. This design allows for easy and efficient replacement of filter cartridges, as they can simply be pulled out and replaced from outside the unit, streamlining maintenance and minimizing downtime.

STANDARD FEATURES

BlastOne Dust Collector Series 6K to 40K CFM

-

-

VERTICALLY MOUNTED CARTRIDGES

Vertically mounted filters have an approximately 30% increased filter life over horizontal filters. This is because the dust can fall off a vertical filter into the waste hoppers, whereas with horizontal filters, the dust

simply calls from filter onto the filter below it. -

BOTTOM ENTRY DUCTWORK

Directing the air this way gives you maximum filter life, removing the risk or premature filter failure due to abrasive particles impacting directly into the filter. The dust entering at the base of the unit is dispersed over all the cartridges, rather than just the cartridges immediately in front of the duct on a side entry unit. -

VACUDYNAMIC HIGH PERFORMANCE BACKWARDS INCLINED BLOWER FAN

The whole Dust Collection system is dependent on the fan. A Vacu-Dynamic fan, with the appropriate vacuum pressure for the ducting design, gives you the highest airflow pressure balanced with energy consumption.

-

-

-

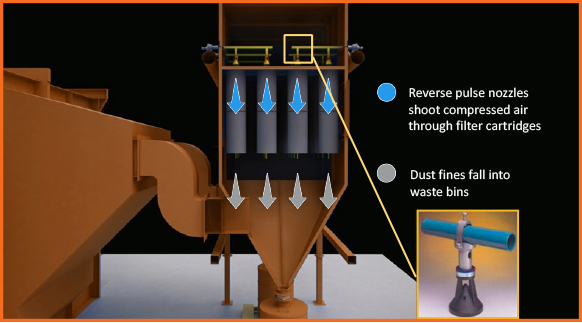

AUTO CLEANING SYSTEM

The Maxi-Reverse Pulse jets provide longer life to your cartridges with our Eco-Clean Pulsing System. Integrated Controls with the entire blast room, allow the dust collector to only run when needed, but also run a cleaning cycle once blasting has ceased. -

2.2 AIR TO CLOTH RATIO OR BETTER

The air to air cloth ratio is comparing the cubic feet of air per minute (CFM) to the square feet of filter media. If this number is too high, you’ll have premature cartridge wear, if its too low, your machine will be too big. Blasting environments dictate an air to air cloth ratio of 2.5:1 or lower. Ample air-to-cloth ration extends the life of your filter cartridges, lowering your overall operational costs.

-

Custom Options for Your Application

-

-

Maintenance Access Platform for easy service

-

VFD Motor Control for variable ventilation capacity

-

Outdoor Package with weather-tight sealed valves

-

-

-

Lower noise and less maintenance vs. screw conveyors.

-

Gentler media handling extends abrasive and equipment life.

-

Ventilation Integration.

-

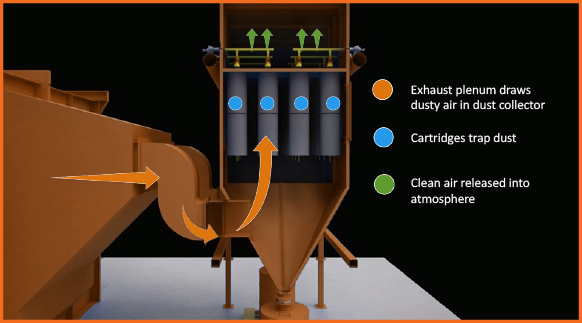

HOW IT WORKS

Abrasive recycling systems ensure blasting operations stay efficient by cleaning and reusing media for continuous production. After elevation, the abrasive passes through an air-wash separator that removes dust, fines, paint flakes, and debris. Clean, reusable abrasive is stored in hoppers above the blast pots, ready for immediate refill. Waste fines are diverted to disposal, while dust-laden air routes to the dust collector—keeping the system clean and compliant. By maintaining a steady flow of recyclable abrasive, these systems reduce costs, improve surface preparation quality, and minimize downtime.

- Dust from the blast room enters the dust collector into the dirty air plenum, the air passes through the filter cartridges, leaving the dust caked on the external. The clean air is either released into the atmosphere or back into the building to conserve heat and energy.

- Using filter sensors, the dust collector automatically self-cleans by sending a quick burst of air backwards through the filters. This creates a shock wave, causing the dust to fall down into the lower chamber.

DUST COLLECTOR SIZING FOR BLASTROOMS

Sizing a dust collector for a blast room is based on maintaining proper airflow to control dust and ensure operator safety. The goal is to achieve an air velocity of 50 feet per minute through the blast room.

-

-

Calculate the cross-sectional area of the room opening (width × height).

Example: 12 ft wide × 15 ft high = 180 sq ft -

Multiply the area by the required velocity (50 ft/min).

180 sq ft × 50 ft/min = 9,000 CFM

-

Your dust collector should therefore supply at least 9,000 cubic feet per minute (CFM) of airflow to maintain clear visibility and effective dust control. This simple calculation helps ensure a safe, compliant, and efficient blasting environment.

My Account

My Account