In the dynamic and safety-conscious world of industrial blast and paint facilities, the decision to upgrade or replace a dust collector is critical for maintaining operational efficiency and protecting worker health. Dust collectors, which are central to facility safety and performance, may require upgrades or replacement due to wear and tear, which could lead to diminished performance and potential health hazards from airborne particles. Prior to installation, careful planning is crucial to ensure the dust collection system is customized to a facility’s specific needs, aligning with both safety standards and operational goals.

The installation process of a dust collector is a complex operation that must be executed with precision to safeguard health and optimize efficiency, demanding thorough understanding and meticulous attention to detail. Regular maintenance of this machinery is non-negotiable; it ensures peak performance, prevents disruptions, and extends the system’s longevity. Expert consulting is invaluable in navigating the intricacies of dust collection systems, providing tailored insights that help facilities make informed decisions. Additionally, selecting the right solutions, services, vendors, and suppliers is paramount, as these decisions have long-term impacts on the functionality and efficacy of the dust collector system. Ultimately, collaborating with professionals in the field not only clarifies the path but also secures the investment and fortifies the commitment to operational excellence. This introduction sets the stage for readers who are seeking to deepen their understanding and address common queries about each step in the process of managing dust collection in industrial environments.

I. Understanding the Need for Upgrading or Replacing

In the fast-paced world of industrial operations, ensuring the efficiency and safety of your blast and paint facility is paramount. One of the most critical components in this process is the dust collector. But how do you know when it’s time for an upgrade or replacement?

Why Consider Upgrading or Replacing?

As with any machinery, wear and tear on dust collectors are inevitable. Over time, they can become less efficient, leading to reduced performance. This not only affects the quality of work but can also pose significant safety hazards. Dust and particles that aren’t efficiently collected can contaminate the air, posing health risks to workers and potentially compromising the quality of the blasting and painting process.

Typical Customer Concerns:

- Is my dust collector outdated?

- Technology is continually evolving. If your dust collector has been in operation for many years, there’s a good chance that newer, more efficient models are now available. Upgrading can introduce these newer technologies, enhancing performance and energy efficiency.

- How do I know if my system is beyond repair?

- Regular troubleshooting and maintenance can address minor issues. However, if you find that repairs are becoming more frequent and costly, it might be more economical in the long run to consider a replacement.

- What are the benefits of upgrading versus replacing?

- Upgrading can enhance the current system with newer parts or technologies, extending its lifespan. In contrast, replacing involves installing a brand-new system, which might be necessary if the current system is incompatible with your facility’s growing needs or if it’s too outdated.

- How often should I assess my equipment’s performance?

- It’s advisable to conduct regular checks on your dust collector’s efficiency. Depending on usage, a quarterly or bi-annual assessment can help in early identification of potential issues.

- Does my dust collection system meet current safety codes and regulations?

- Standards and regulations change frequently, as do abrasives used in blasting processes, so it’s essential to know whether or not your dust collection system meets current requirements for the intended use.

Solutions We Offer:

- Industrial Dust Collection System Troubleshooting: Our team of experts can diagnose issues with your current system, offering insights into whether repairs or a complete overhaul is needed.

- Industrial Dust Collection System Repair: We provide top-notch repair services, ensuring your system runs efficiently and safely.

- Industrial Dust Collector Replacement: If your current system is beyond repair, we offer state-of-the-art dust collectors tailored to your facility’s needs.

- Industrial Dust Collector Upgrade: Looking for enhanced performance without a complete replacement? Our upgrade solutions can breathe new life into your existing system.

II. Pre-Installation Considerations

In the realm of industrial operations, particularly in blast and paint facilities, the dust collector stands as a sentinel of safety and efficiency. But before you embark on the journey of installing a new dust collector, there are pivotal considerations to bear in mind. These pre-installation steps are not just procedural but are the foundation of a system that will serve your facility for years to come.

Why is Pre-Installation Planning Crucial?

Every facility is unique, and so are its requirements. Whether your facility specializes in abrasive blasting, powder coating, or spray painting, the dust collector needs to be tailored to these specific operations. This customization ensures that the system not only performs optimally but also adheres to safety standards, protecting both the workforce and the environment.

Typical Customer Concerns:

- How do I determine the right design for my facility?

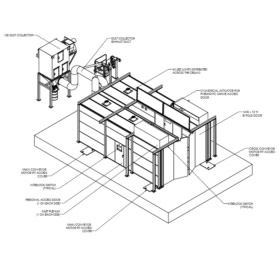

- The design of a dust collector is influenced by several factors, including the volume of dust generated, the type of particles, and the desired air quality. Our team of experts in industrial dust collection system design will work closely with you to understand your facility’s needs and design accordingly.

- What role does engineering play in this process?

- Engineering is the backbone of the installation process. It ensures that the system is not only designed well on paper but also functions seamlessly in the real world. Our engineering team ensures that every component, from filters to ducts, is optimized for performance, safety, and longevity.

- Is there a difference in dust collectors for different processes like abrasive blasting, powder coating, or spray painting?

- Absolutely. Each process has its unique set of requirements. For instance, a dust collector for abrasive blasting might need to handle larger particles and higher volumes than one for spray painting. We offer specialized solutions, ensuring that your specific needs are met.

III. Installation Process

In industrial operations, the installation of a dust collector stands as a pivotal moment. It’s not just about placing a machine in a room; it’s about integrating a system that will safeguard the health of the workforce, ensure the quality of work, and optimize operational efficiency. As you consider this significant step, it’s natural to have questions and concerns. Let’s address some of the typical queries that customers often have.

Why is the Installation Process So Vital?

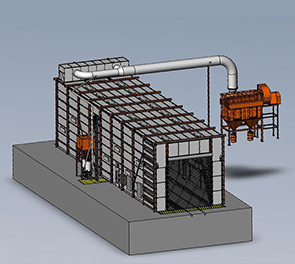

The heart of a blast and paint facility is its machinery, and the dust collector is no exception. A well-installed dust collector not only ensures optimal performance but also minimizes risks, ensuring a safe and healthy environment for workers. Whether it’s the main unit, the ductwork, or the airflow mechanisms, every component needs precise installation.

Typical Customer Concerns:

- How long will the installation process take?

- The duration of the installation process can vary based on the size and complexity of the system. However, our team of experts in industrial dust collection system installation is trained to work efficiently, ensuring minimal downtime for your facility.

- Will the installation disrupt my facility’s operations?

- We understand the importance of continuous operations for your business. Our team will collaborate with you to schedule the installation at a time that minimizes disruptions.

- How do specialized installations, like those for blast rooms or paint booths, differ?

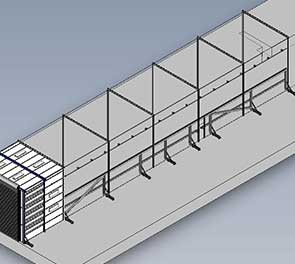

- Specialized installations, such as those for blast rooms or paint booths, have unique requirements. These systems are designed to handle specific contaminants and volumes, and their installation ensures that they capture and filter out particles effectively. Our team is well-versed in these nuances and will ensure that your specialized dust collector is installed to meet these specific needs.

Solutions We Offer:

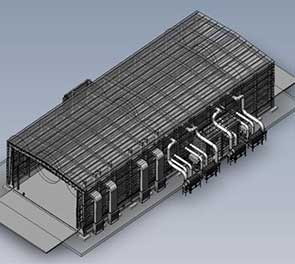

- Industrial Dust Collection System Installation: Our comprehensive installation service ensures that every component of your dust collector, from the main unit to the ductwork, is set up for optimal performance.

- Blast Room Dust Collector Installation: Blast rooms have specific requirements given the volume and type of particles involved. Our installation process for blast rooms is tailored to ensure that these contaminants are effectively captured and filtered.

- Paint Booth Dust Collector Installation: Paint booths present their own set of challenges, with fine particles and potential fumes. Our installation process for paint booths focuses on ensuring effective filtration and maintaining pristine air quality.

With our expertise and commitment to excellence, you can be assured that your dust collector will be reliable in your facility. Trust in our experience to provide a seamless installation process, setting the stage for years of optimal performance.

IV. Maintenance and Regular Upkeep

In the bustling world of industrial operations, machinery is the lifeblood that keeps processes flowing smoothly. However, like any valuable asset, the machinery requires regular care and attention. When it comes to dust collectors in blast and paint facilities, this care becomes even more paramount. A dust collector is a key player in ensuring the efficiency of operations. Let’s address the importance of maintenance and some common concerns that customers often have.

Why is Regular Maintenance Non-Negotiable?

A dust collector, while robust, is not invincible. Over time, filters can clog, parts can wear out, and leaks can develop. Regular maintenance ensures that these issues are caught early, preventing minor problems from escalating into major breakdowns. Moreover, a well-maintained system operates at peak efficiency reduces operational costs.

Typical Customer Concerns:

- How often should I schedule maintenance checks?

- The frequency of maintenance checks can vary based on the usage and the environment of the facility. However, as a general guideline, quarterly checks are advisable for most industrial settings. Our team of technicians can provide a tailored maintenance schedule based on your specific needs.

- What does a typical maintenance check involve?

- A standard maintenance check involves cleaning filters, inspecting for leaks, checking the integrity of all parts, and ensuring the system is operating efficiently. Our technicians will also assess the system’s compliance with safety standards, ensuring that your facility remains a safe environment for all.

- Can minor issues be addressed during these checks, or will there be downtime?

- Many minor issues can be addressed on the spot during routine maintenance checks, minimizing downtime. For more significant concerns, our technicians will work with you to schedule repairs at a time that causes the least disruption to your operations.

V. Consulting and Expertise

In the intricate world of industrial operations, especially in blast and paint facilities, decisions around machinery and systems can have lasting impacts. Whether you’re considering an upgrade or a complete replacement of your dust collector, the guidance of seasoned experts can be the difference between a good decision and a great one. But why is consulting so crucial, and what can you expect from this process? Let’s explore this further and address some common queries that customers often have.

Why is Expert Consulting Essential?

The realm of dust collection is vast and complex. While the basic principles might seem straightforward, the nuances of design, efficiency, safety, and compliance can be overwhelming. Experts, with their years of experience and deep industry knowledge, can navigate these complexities, offering insights and recommendations that are tailored to your facility’s unique needs.

Typical Customer Concerns:

- Why can’t I make decisions based on my own research?

- While independent research is valuable, the field of dust collection is ever-evolving, with new technologies, regulations, and best practices emerging regularly. Consultants and experts are immersed in this world daily, ensuring that their recommendations are not only current but also foresee future industry trends.

- How do engineers enhance the consulting process?

- Engineers bring a technical depth to the consulting process. They can take the insights and recommendations of consultants and translate them into actionable designs and plans. Their expertise ensures that the system is optimized for performance, longevity, and safety.

- Will the consulting process be tailored to my facility’s specific needs?

- Absolutely. Our team of specialists, experts, and professionals will work closely with you to understand the unique challenges and requirements of your facility. This personalized approach ensures that the solutions offered are perfectly aligned with your operational needs and goals.

VI. Solutions and Services

In the dynamic landscape of industrial operations, particularly in blast and paint facilities, the importance of a tailored approach cannot be overstated. Every facility, with its unique challenges and objectives, demands solutions that are not just effective but also bespoke. As you navigate the path of upgrading or replacing your dust collector, understanding the range of solutions and services available can be pivotal. Let’s delve deeper into what this entails and address some of the common queries that customers often have.

Why Tailored Solutions Matter?

While the core objective of a dust collector remains consistent – to ensure clean air and safe operations – the means to achieve this can vary widely based on the facility’s specific processes and challenges. Whether you’re dealing with the intricacies of abrasive blasting, the nuances of powder coating, or the specifics of spray painting, a tailored solution ensures that your system is optimized for your unique needs.

Typical Customer Concerns:

- How do I know which solution is right for my facility?

- The right solution hinges on a thorough understanding of your facility’s operations, challenges, and objectives. Our team of experts will conduct a comprehensive assessment, ensuring that the solutions recommended are perfectly aligned with your specific needs.

- Are general services sufficient, or do I need a custom-designed system?

- While general services can address standard needs, custom-designed systems offer a level of optimization that’s tailored to your facility’s unique challenges. Depending on the complexity of your operations and the specific requirements, a custom solution might offer better long-term value and performance.

- How do service providers ensure that the solutions align with industry best practices?

- Our team stays abreast of the latest industry trends, technologies, and best practices. This continuous learning ensures that the solutions and services we offer are not only current but also foresee future industry developments.

My Account

My Account