Industrial Wind Tower Blast & Paint Facilities

Many wind energy fabrication facilities are under pressure to reduce costs and improve efficiency. With our blend of experience and advanced technologies, customized to your specific operating requirements, we can rapidly ramp up your productivity and drive down your costs. Through supplying better equipment, better processes and better staff training, BlastOne can partner with you to revolutionize your corrosion control facilities. Our partnership with you will set in motion better outcomes, now and in the future.

Wind towers are erected with an estimated 25-30 year life. Often they are located in a harsh environment. High rainfall, coastal or marine exposure, or temperature extremes can all cause coating failure. The double whammy of coastal or marine of salt and water can accelerate the process of corrosion.

Consequently, an impenetrable and durable protective barrier is needed to protect wind towers from corrosion. These assets are high value and if they become critically corroded will result in a loss of both energy production and company profit.

Abrasive blasting will ensure the surface is ready for optimum coating application, which lengthens the lifespan of the coating.

A few common issues we’ve found from working with the Wind Tower industry:

The Best Blasting Equipment

ABRASIVES

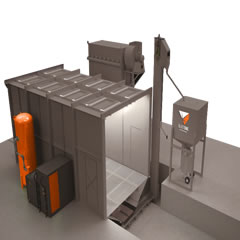

Wind towers are usually blasted in a chamber in three sections per tower. Commonly used abrasives include GMA Garnet and metallic grit. Both the interior and the exterior of the tower require blasting. The exterior of a wind tower has a requirement for greater corrosion than the interior and is often given a coat of hot metal spray prior to top-coating. Steel grit is used if a hot metal spray coating will be applied to the tower’s exterior because of grit’s ability to provide an angular profile. If the exterior of the tower is not coated with a hot metal spray prior to top coating, then GMA Garnet will be used on both the inside and outside of the towers.

ROBOTIC BLASTING EQUIPMENT

Due to the repetitive nature of the work, robotics have been proven to reduce production costs and guarantee an excellent, consistent production. Because robots are not subject to fatigue, high flow blasting equipment is requires to take advantage of their productivity gains. This means large port valving, large bore blast hoses, high volume compressors and bulk blast pots.

Coating Types and Equipment

With metal spraying, a molten zinc metal spray is applied using a process similar to MIG welding. Next, an epoxy intermediate top coat, or urethane coating is applied. This type of system is required to ensure long coating life in a harsh environment.

A second option is a three coat system of a zinc rich primer, an epoxy intermediate coat and then a urethane top coat. The urethane top coat maintains good gloss levels and is, to a certain degree, self-cleaning. Epoxy coatings do not have good UV resistance, chalking easily. Hence the requirement for a urethane top coat.

When coated without a metal spray base coat, typical dry film thickness (DFT) is a total of 350-500 microns which is 14-20 mils. With a metal spray base coat, because of its rough finish, the combined intermediate and top coats will normally have a dry film thickness of 16 mils.

PAINTING EQUIPMENT

When applying hot metal spray, dedicated equipment is used. This equipment is similar to that used in a mig or oxy welding system. A wire or powder is molten with a flame or electric arc. The following intermediate and top-coats will be applied with an airless sprayer. When hot metal spray is not used, the entire coating system will be applied with an airless sprayer. Airless spraying enables the highest application rates. It also has a high transfer efficiency; this means more coating stays on the surface being coated rather than blowing away in the wind. The downside is that the finish is inferior to an air spray system. Air-assisted airless spraying blends both systems for a better quality finish for airless spraying, albeit not at the production rate at the levels of non-air-assisted airless spraying. Air-assisted airless spray systems feed a small amount of air up to the front of the gun to break up the paint spray particle sizes for a better finish.

My Account

My Account