RECOVERY & RECYCLING SYSTEMS

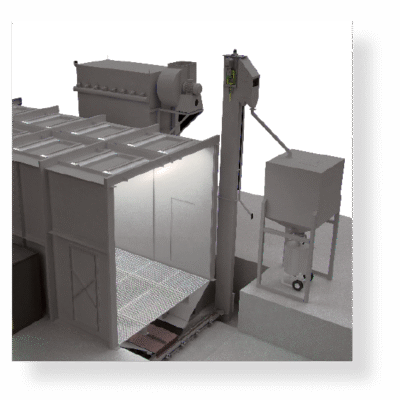

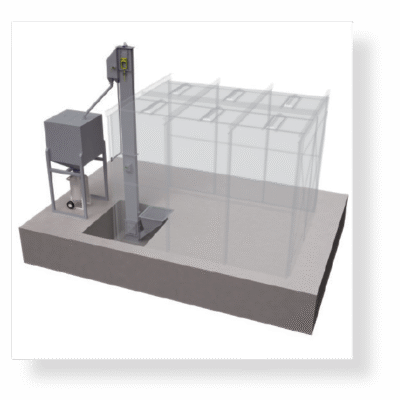

Whether you blast ten hours a week or two shifts a day, the right recovery floor and recycling circuit is the difference between constant shoveling and continuous blasting. BlastOne designs underfloor systems that automatically convey abrasive to a central elevator and air-wash separator, removing dust, fines, paint flakes, and trash before returning clean media to storage above the blast pots.

ABRASIVE RECOVERY

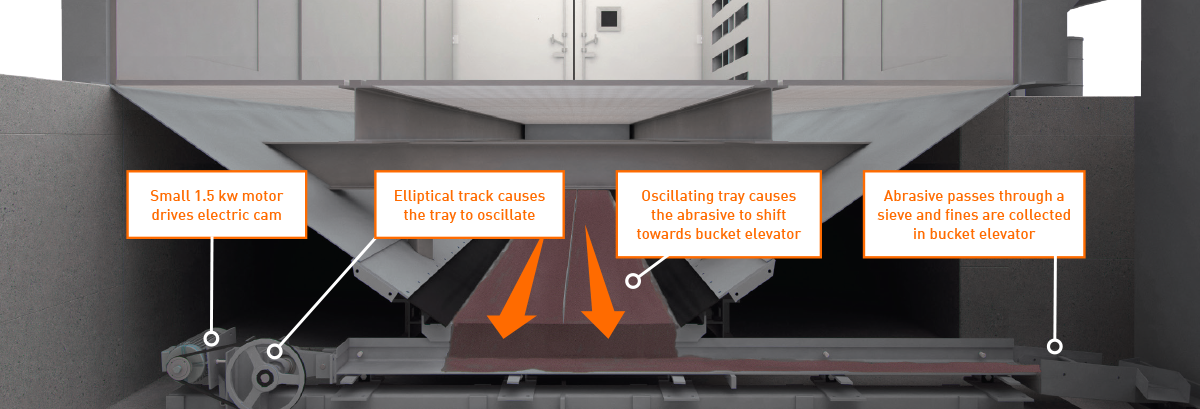

Our recovery floors use a low-horsepower oscillating conveyor beneath grates to quietly move media toward a bucket elevator—no noisy screw augers or high-wear flights. The elliptical track drives a tray motion that advances grit, then the stream passes through screening to remove oversize debris.

Floor Configurations

Full Floor

A full floor recovery system becomes fully automatic and no manual clean-up is required, this system utilizes a Grate Floor and underfloor hoppers to capture every particle of spent abrasive from the blast room.

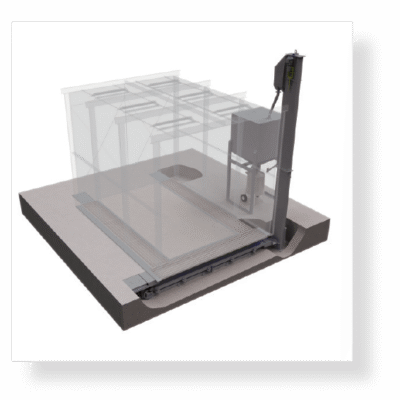

Partial Floor U-Shaped

U- or H-Shaped Conveyor Systems move abrasive along blast room walls to a central recovery point. Ideal for under 40 hours per week use, with most abrasive falling to the walls and the rest swept in.

Partial Floor

A semi-manual system that includes a single inground trench and cross conveyor, allowing you to sweep all the abrasive into the trench. It’s cost effective and typically used when the blasting operation is required less than 20 hours per week.

Sweep In & Shovel In

This is a semi-manual system with no abrasive conveyors, it just has a simple belowground hopper in the blast room, connected directly to the abrasive recovery system. It is typically used when the blasting operation is required less than 10 hours per week.

Oscillating Conveyors

Properly sized intake/exhaust plenums and a blasting-specific dust collector maintain visibility and protect filters, supporting consistent recovery and operator safety.

-

-

Lower noise and less maintenance vs. screw conveyors.

-

Gentler media handling extends abrasive and equipment life.

-

Ventilation Integration.

-

ABRASIVE RECYCLING

Abrasive recycling systems ensure blasting operations stay efficient by cleaning and reusing media for continuous production. After elevation, the abrasive passes through an air-wash separator that removes dust, fines, paint flakes, and debris. Clean, reusable abrasive is stored in hoppers above the blast pots, ready for immediate refill. Waste fines are diverted to disposal, while dust-laden air routes to the dust collector—keeping the system clean and compliant. By maintaining a steady flow of recyclable abrasive, these systems reduce costs, improve surface preparation quality, and minimize downtime

What Gets Removed?

-

-

Dust and fines

-

Paint flakes and trash

-

Oversize debris via screens/sieves

-

Benefits You’ll See

-

-

Lower media spend via high recovery rates

-

Cleaner booths and faster changeovers

-

Improved safety and environmental compliance

-

Common Media

STEEL GRIT is the most common recyclable abrasive in blast rooms; systems are configurable for garnet and other media.

SYSTEMS & OPTIONS

-

-

Storage Hoppers | Gravity-fed, dual-outlet hoppers simplify pot refills and keep production continuous.

-

Intelligent Controls | Predictive maintenance, interlocks, and integrated pulsing reduce downtime and energy use.

-

Dust Collectors | Blasting-specific designs (vertical cartridges, bottom entry, auto-pulse) extend filter life.

-

My Account

My Account