AMPHIBLAST SKID ON TRUCK IMPROVES PRODUCTION AND SAFETY

Somervile, Victoria, Australia

My Account

My Account

Catalog | Locations | Bulk Order | Quote List

Northern Construction and Drilling is a company that provides plumbing and drainage solutions, along with blasting pipeline projects. The project location was at Somerville, Mornington Peninsula, where pipeline fabrication and repair works were underway. The company was experiencing issues with their current process of hand prep and a massive increase in workload. They approached BlastOne to provide a new blast system requirement that could meet their requirements.

The unique challenges faced by the company were the urgent site requirements for training and commissioning of the blast setup with a very short same-day solution offered. Dust containment and position of pipeline were also important considerations during the project.

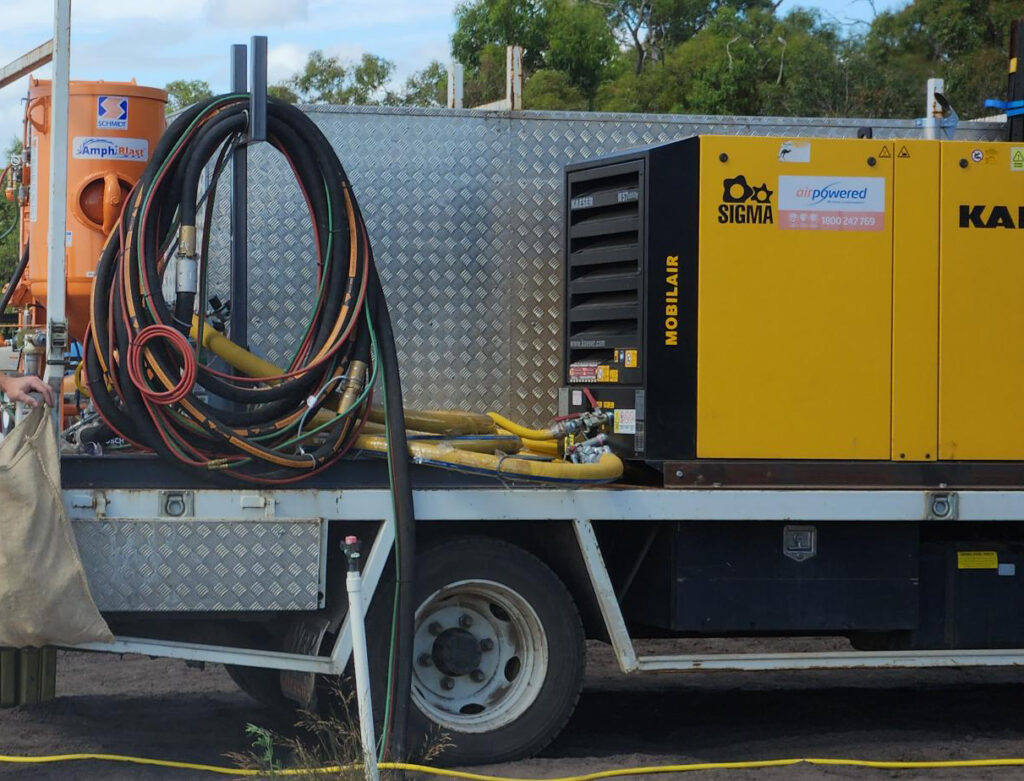

BlastOne provided training and a full AmphiBlast 3.5 skid with PPE which was installed onto the back of their truck. The client’s best-case outcome was to be able to blast in-house with full support.

The final result was a vast increase in production and meeting their targets for the pipeline project. The SnakeBite Flex blast nozzle used in the project also led to successful safety improvement for pipeline work in confined spaces as it allowed for extra movement and better control of the nozzle in confined spaces.

The project undertaken by Northern Construction and Drilling with the support of BlastOne led to significant improvements in production and safety. The customised solution provided by BlastOne met the client’s requirements and resulted in a successful outcome.

Dust collection units are an important component for blasting site environmental and personnel safety. The removal of dust and other hazardous air particles protects the employees on site, while also preventing harmful contaminates from escaping into the atmosphere without relying on personal respiratory equipment alone.

A dust collector is used to provide ventilation inside containment structures to maintain operator visibility and maintain the encapsulated area under a negative pressure. It is also important to dilute the levels of hazardous substances within the contained area to levels below the minimum requred protection factor for personnel within, as well as respirator equipment limitations.

Many older coatings contain a high percentage of lead which when pulverized into powder by abrasive blasting can form a hazardous and toxic dust. Company legal obligations on project sites are now requiring that a full dust-tight containment structure encapsulates all blasting operations to minimize the danger to personnel and the environment.

We love to talk to customers and help them make the best decisions when purchasing equipment.

You can reach us via our Live Chat, Email, Phone, and Online Form.

Registration is required to create a Quote.

Click Here to Login or Register.