Why Dehumidification Matters

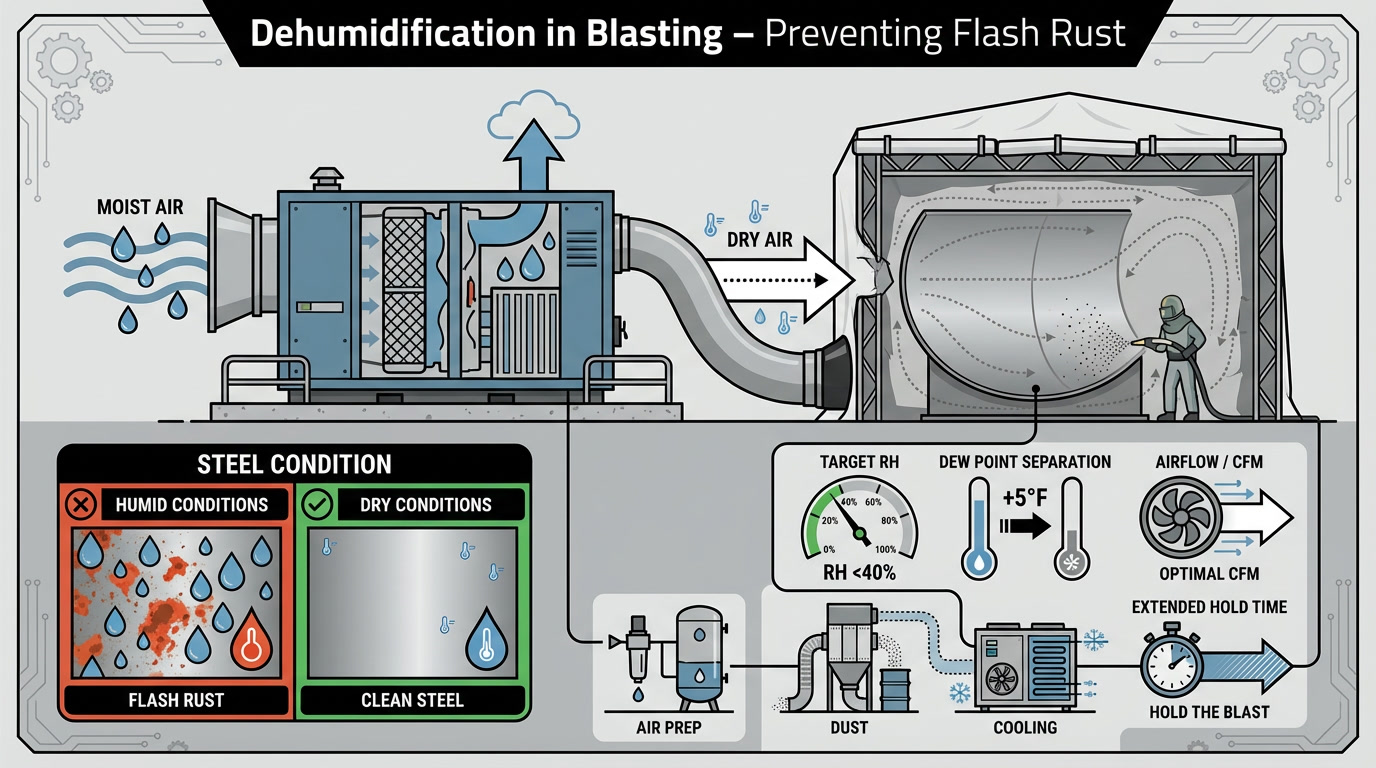

Freshly blasted steel is extremely vulnerable to flash rust, which can develop rapidly when humidity is high or when the steel temperature approaches the dew point. On large industrial projects such as tanks, ship hulls, bridges, and refinery structures, this can cause costly delays or coating failures.

Dehumidification allows crews to “hold the blast” by keeping the environment below critical humidity levels. With controlled RH, steel surfaces remain clean and coating-ready for extended periods. This is essential in humid or coastal climates.

Industrial Dehumidification Systems:

https://www.blastone.com/product/portable-onsite-dehumidification-systems/

How Industrial Dehumidifiers Work

BlastOne desiccant dehumidifiers pull ambient air across a rotating silica-gel rotor that absorbs moisture. A heated regeneration zone removes the captured moisture, discharging it outdoors, while sending dry, conditioned air into the containment.

This process achieves RH levels below 40% and can reach as low as 10–20% depending on unit size and conditions. Desiccant systems outperform refrigerant dehumidifiers in industrial blasting applications.

Full DH Equipment Category:

https://www.blastone.com/product-category/blasting-uhp-site-equipment/ventilation-other-field-equipment/dehumidification-dh-equipment-parts/

Sizing and Setup for Industrial Projects

Proper sizing is essential for moisture control. Industrial dehumidifiers are available in capacities from 2,400 CFM to more than 10,000 CFM. Small containments may require a single mid-size unit, while large tanks or ship holds often utilize multiple systems.

Place the dehumidifier outside the containment and use ducting to supply dry air inside and exhaust moist air outside. Maintain slight positive pressure and distribute dry air evenly to avoid stagnant pockets.

Preventing Flash Rust in Practice

With dehumidification, blasted steel can remain rust-free for days or even weeks. For example, a 6,000 CFM BlastOne unit operating at roughly 40% RH kept a 120-ft tank interior clean despite outdoor RH levels above 85%.

Dehumidification must be combined with proper contamination removal. Soluble salts can still cause corrosion even in dry environments, so testing remains essential.

Worker, Environmental, and Operational Benefits

Dry air improves visibility, reduces abrasive clumping, and enhances worker comfort in full PPE. Desiccant units generate some heat, so supplemental cooling may be needed in hot conditions.

DH Equipment & Accessories:

https://www.blastone.com/product-category/blasting-uhp-site-equipment/ventilation-other-field-equipment/dehumidification-dh-equipment-parts/

Integration with Dust Collection Systems

Dehumidifiers and dust collectors must be airflow-balanced. Dust collectors generally maintain slight negative pressure to prevent dust escape while allowing conditioned dry air to circulate.

Industrial Dust Collectors:

https://www.blastone.com/product-category/dust-collection/

Power, Reliability, and 24/7 Operation

BlastOne’s dehumidifiers are available in skid-mounted or trailer-mounted formats and can operate continuously for long-duration industrial projects such as shipyards, tank farms, bridges, and petrochemical facilities.

Additional Moisture Control Tools

Moisture separators help reduce water in compressed air systems and are recommended alongside primary air dryers.

Portable Moisture Separator (Schmidt):

Wet-blasting rust inhibitors like Hold*Blast™ can delay flash rust when DH is unavailable, though they may require rinsing before coating.

Summary

Dehumidification is a critical control measure for industrial abrasive blasting. It prevents flash rust, improves coating performance, and supports long-duration blasting operations without surface degradation. Proper sizing, airflow management, and monitoring ensure reliable results on large-scale projects.

My Account

My Account