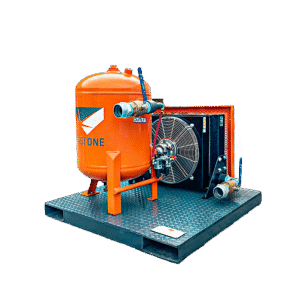

Today we’re going to go over a few things that you need to know before running your air dryer onsite.

What Is The FRL?

The first main part to any air dryer is it’s FRL system. The Filter, Regulator Lubricater.

Regulator

Customers call in daily and ask, “Hey, what air settings should this regulator be set to?” And on average, we set regulators around 80 PSI when running the fan motor. That gives us the best cooling without overrunning the motor and from there we would move on to the oiler.

Lubricator

When we get to the oiler, this should be checked every day. We like to hit four drops per minute of any ten weight motor oil. If you are not going through the oiler cup in a couple of days, you’re probably running your motor too lean and you’re going to run into issues where the motor locks up. Note: It holds any ten weight motor oil. Just be aware that if you change the viscosity of your oil at all, you may need to readjust your oiler on the top.

The whole purpose of the FRL is to lube the pneumatic motor. This pneumatic motor has shims inside of the internals and the inlet air catches the shims and spins the fan motor. The fan motor then pushes air through the intercooler, which cools the air coming from the compressor, which helps pull moisture out. This is a very important part which should be maintained daily.

Drainage

The next thing we’re going to get into is how often you should drain the water from the unit.

- Customers will crack the ball valve on the bottom of the vessel, just enough to get rid of any moisture that may be building up. There’s a drain in the very bottom of the vessel, as well as the outlet and inlet moisture strainer. And what this does, by just barely cracking them, is get rid of any moisture that it may build up over time and it takes the human error out of it.

- The second way that people typically do it is on every break they’ll come in, they will grab the ball valves and they’ll purge it out good. They’ll blow any oils they may have come from the compressor or moisture or anything like that and they’ll do the main drain and it will shoot a lot of water out.

You will find that a 1600 CFM compressor puts out around five gallons of water an hour. So there’s a lot of moisture that you’re getting rid of with a bigger unit.

Deliquescent

The next thing we want to pay attention to is the deliquescent.

Customers call and say, “Hey, my dryer may be a couple of bags low on deliquescent, does it actually affect the way the unit runs?”

And the answer is, yes, it does. You always want to make sure that the deliquescent is full.

Also make sure it’s not contaminated with oil from a bad compressor that you may have gotten on rent. If there’s any contaminants in there, you’ll see brown oil over top of the deliquescent tablets, something else you want to get into is how often should you actually clean out the whole internals of the vessel. It should be done yearly as a good practice.

- You will find that if you fill this whole entire chamber up with water when it’s depressurized. It’ll take about 2 hours to melt all the deliquescent out of the system.

- You purge it out, put a good solvent in there, rinse it out at the end of the year or the end of the season and get ready for the next year.

Intercooler

And the last thing we wanted to discuss is ensuring that the fins on the top your intercooler is cleared of debris.

You’ll find sometimes if you’re close to a water tank or any kind of tall object, that abrasive will actually load and fill the top of the fan. And if your fan doesn’t actually blow that abrasive back out, it sits lodged in the coil above. If it’s clogged, you won’t be able to move air through it and then the unit won’t cool like it’s supposed to. So you want to make sure you rinse that thoroughly with a solvent, blow it out with an air hose if you can, and ensure that you’re getting proper air flow to the top of the unit.

My Account

My Account