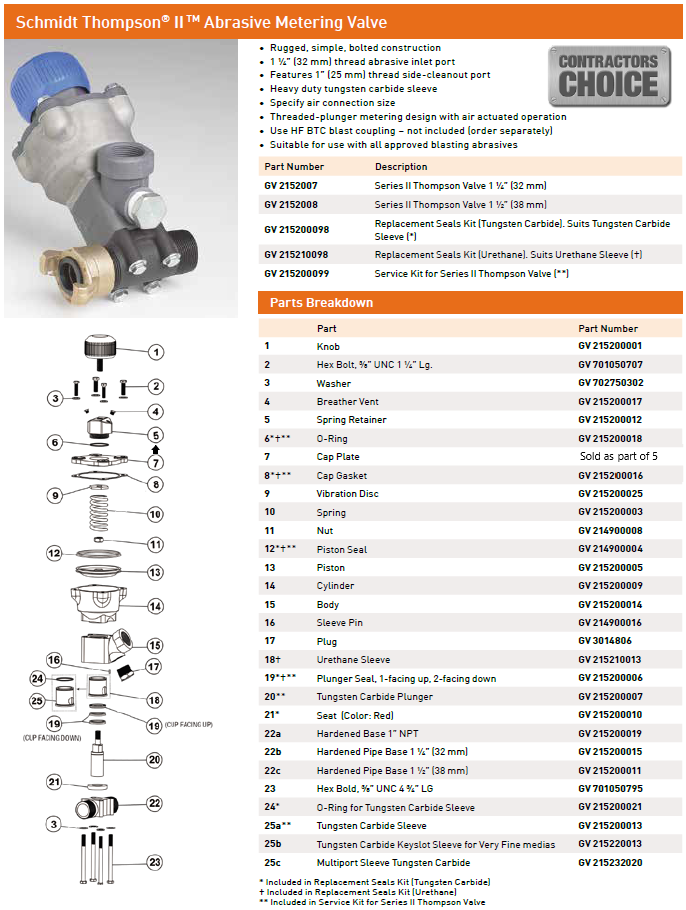

Schmidt Thompson® II Abrasive Metering Valve

Sku: P-GV2152

Thompson Valve II: The Ultimate Solution for Accurate Abrasive Metering Are you in search of a reliable and precise abrasive metering valve for your sandblasting equipment? Look no further than the Thompson Valve 2. The Heart of Sandblasting: Thompson Valve II The Thompson Valve II, designed by the legendary Bob Thompson, acts as the carburetor for your sandblasting machine. By controlling the flow of abrasive media into the high-pressure air stream, the Thompson Valve II ensures accurate and consistent results. Its innovative design has made it the go-to valve for sandblasting professionals. Precise Measurement with Virtual Position Indicator (VPI) The Virtual Position Indicator (VPI) of the Thompson Valve II provides a visual gauge of the valve's openness. The graduation marks make precise measuring simple, eliminating the need for counting turns of the knob. Fail-Safe Design for Optimal Safety This normally closed valve is standard on multiple outlet sandblasting machines and is designed for fail-safe operation, providing optimum safety for the operator. The distinct blue knob also makes it easily recognizable from a distance. Fast Start/Stop for Spot Blasting The Thompson Valve II allows for fast and efficient control of the abrasive flow. This is particularly useful for projects that require spot blasting, where only small areas or rust spots need to be removed. The fast start/stop control helps prevent the "dragging" of the blast and any damage to the coating in between. Abrasive Cut-off and Blowdown Option For added convenience, a remote abrasive cut-off is available for Thompson Valve II systems. This allows you to stop the flow of abrasive while continuing to blow air only, providing an easy way to clear the abrasive blast hose and blow the blasting area clean of abrasive. My Account

My Account