SIGNS YOU NEED TO REPLACE YOUR BLAST NOZZLE:

- You can tell there is wear and tear from just removing the nozzle from the nozzle holder

- There are clear cracks on the nozzle cover

- You feel less of a back thrust from the nozzle compared to other days

- There is no whistle sound while blasting

- Using a Nozzle Analyzer Gage to check how worn the inside of your nozzle is

- If your blast pot is clearing out way faster than usual and if your nozzle has grown in size

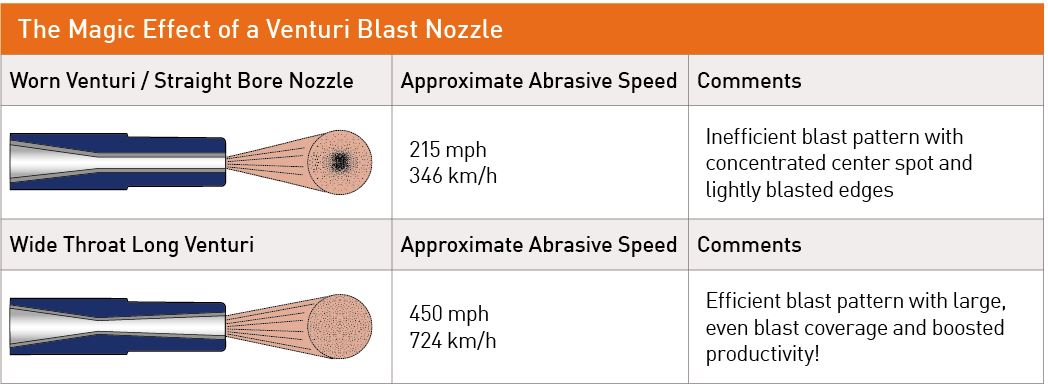

This is resulting in lower efficiency and using more abrasive. This could actually mean your abrasive is working up to 40% slower.

There might also be an inconsistent flow of air and abrasive.

My Account

My Account