Containment Methods for Abrasive Blasting Projects

Protecting the Environment, Workers, and Coating Quality

Containment is an essential component of any abrasive blasting project. Proper containment systems protect the environment, safeguard workers and the public, and maintain surface cleanliness for optimal coating adhesion. Many projects—especially bridges, water tanks, pipelines, and shipyards—are legally required to use containment systems to meet environmental standards.

Why Abrasive Blasting Containment Matters

During blasting, large volumes of dust, spent abrasive, and paint debris (often containing hazardous materials) are released into the air. Without proper containment, these pollutants can contaminate surrounding soil, waterways, and air.

- Environmental Protection – Captures spent abrasive, paint chips, and debris to prevent contamination.

- Worker & Public Safety – Controls airborne dust and flying debris, helping meet OSHA and EPA regulations.

- Quality Control – Maintains a clean work environment, preventing dust or moisture from contaminating freshly blasted surfaces.

Go deeper: Dust Collectors & Air Filtration Systems, Blast Booth & Containment Systems

Levels of Containment

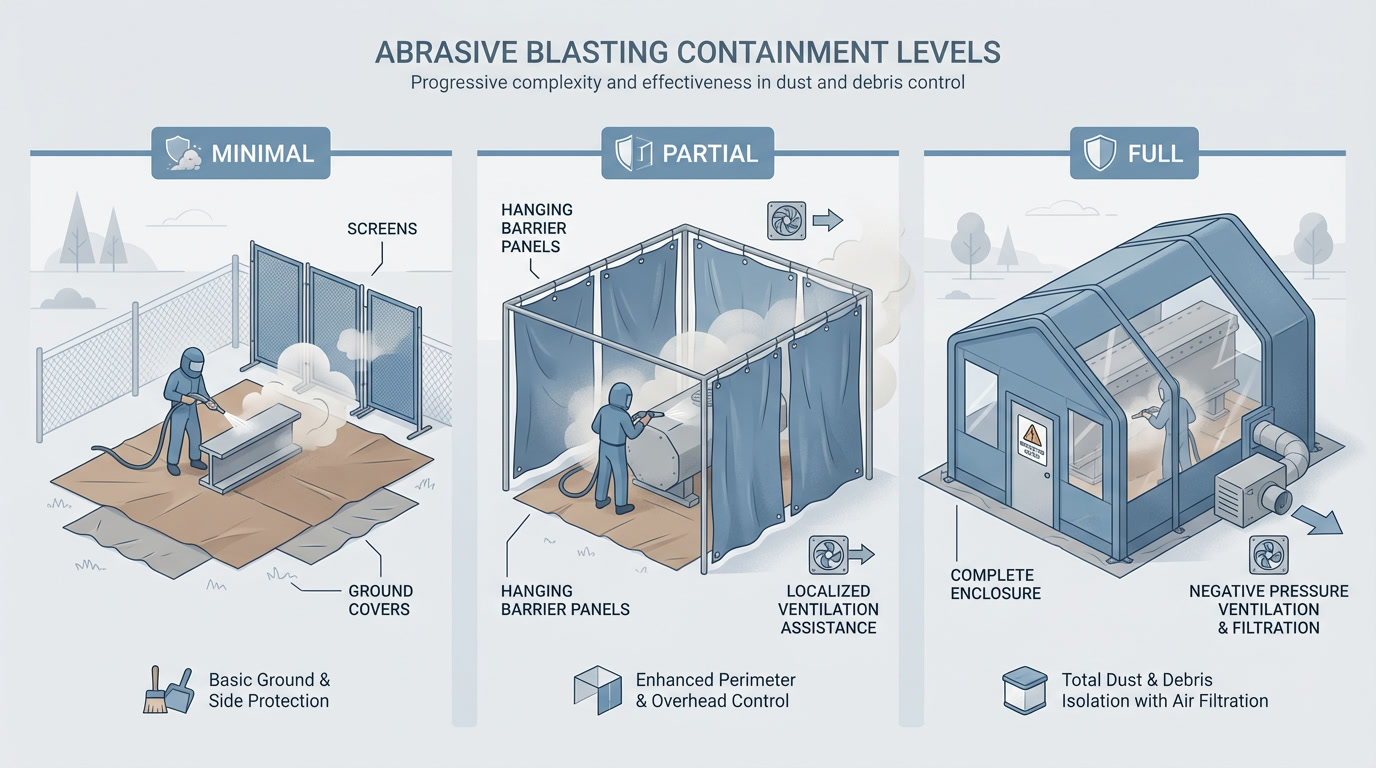

Open-Air Minimal Containment

Basic containment may consist of ground tarps and perimeter screens. Collects debris for cleanup and provides minimal dust suppression. Best suited for non-hazardous coatings or open-area work.

Recommended products: Ground Tarps & Sheeting

Partial Containment

Partial containments use tarps or curtains to surround one or more sides of a work area. Common in building facades or ship-hull work where full enclosures are impractical. Controls most debris, improves cleanup efficiency, and allows for airflow and accessibility.

Related equipment: Scaffold Enclosure Systems & Containment Supplies

Full Containment (Class 1A/1B)

Fully encloses the structure with reinforced polyethylene sheeting or shrink-wrap, maintaining negative air pressure via dust collectors to prevent dust leakage. Entry is through sealed zippered doors or flaps. Essential for hazardous coating removal, bridge rehab, tank blasting, or marine work.

Related products: Containment Sheeting (Fire-Retardant Poly), Zippered Access Doors & Containment Accessories

Containment Materials & Best Practices

- Reinforced Polyethylene Sheeting – Typically 6–10 mil with scrim reinforcement; choose fire-retardant when required.

- Shrink-Wrap Plastic – Heat-shrunk to form a tight, drum-like enclosure; ideal for high-wind environments or irregular shapes.

- Canvas/Fabric Tarps – Useful for splash or grit containment, but limited dust control.

- Rigid Panels (Plywood or Metal) – Used when reusable or long-term containments are needed.

Pro tip: For dust containment, overlap lower sheets inside higher ones; for rain-shed protection, overlap opposite.

Engineering & Structural Considerations

- Scaffolding must be engineered for wind load—containment sheeting acts like a sail.

- Use secure ties (bungees, clips) every 2–3 ft; double up at corners and edges.

- In cold weather, choose sheeting rated for low temperatures to avoid brittleness.

- Ensure fire-retardant compliance when blasting hazardous coatings.

Check containment supplies: BlastOne Containment Solutions

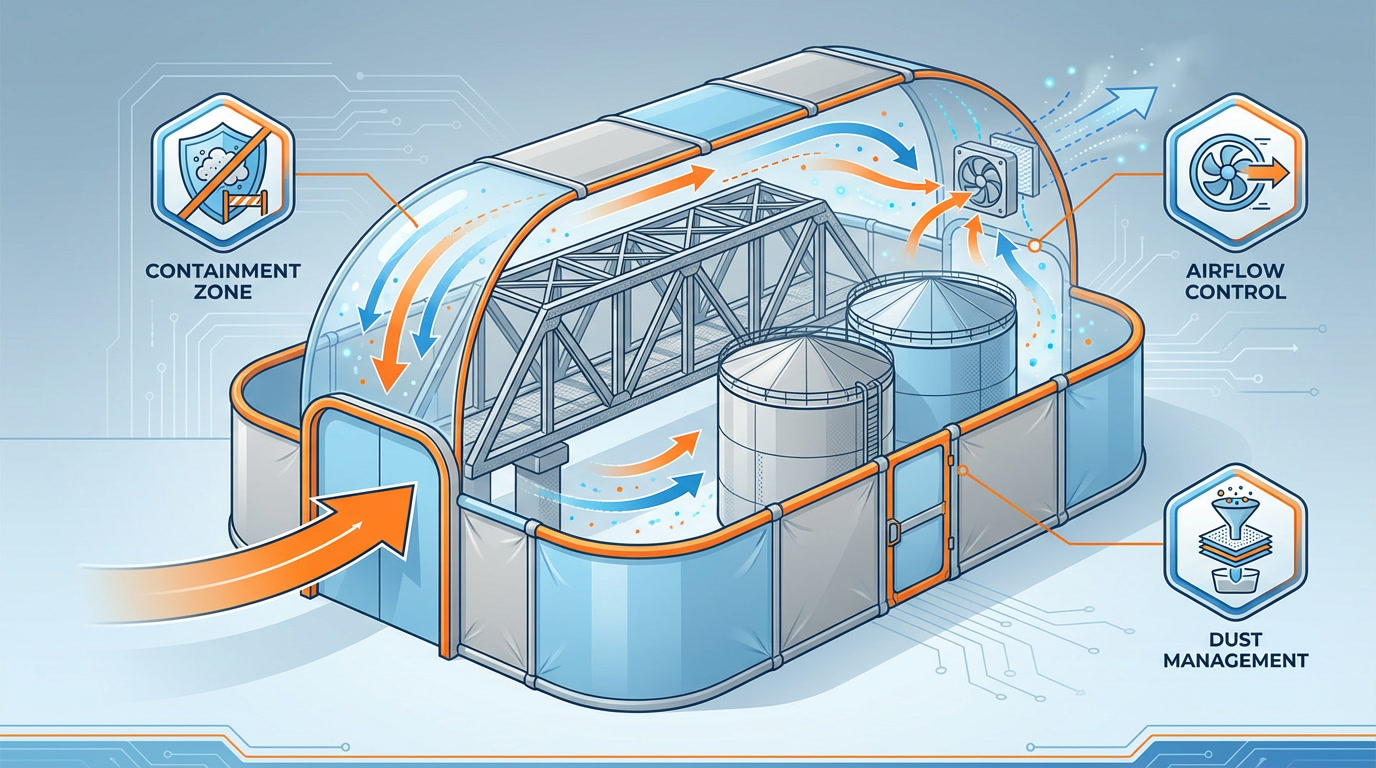

Negative Air, Dust Collection & Ventilation

Full containments should maintain slight negative air pressure to keep dust inside and ensure safe working conditions. Attach a dust collector or ventilation fan to continuously exhaust air and filter contaminants. For hazardous coatings, use HEPA filtration.

Recommended equipment: BlastOne Dust Collection Systems, Portable Dust Collectors & Air Scrubbers

Debris Management & Abrasive Recovery

- Use heavy-duty floor liners (plastic or plywood) for easier cleanup.

- Employ industrial vacuums or abrasive recovery units to reclaim spent media.

- Recycle reusable media (e.g. garnet or steel grit) to reduce waste and cost.

See Abrasive Recovery & Recycling Systems for full solutions.

Containment for Hazardous Coatings

When removing lead-based paint or other hazardous coatings:

Ensure airtight seals, utilize HEPA dust collection, and provide decontamination units for workers before exiting. Follow environmental and safety regulations as applicable.

Alternative Containment: Vacuum Blasting

When traditional containment isn’t feasible, vacuum blasting offers a low-dust alternative. The blast head immediately vacuums up debris and abrasive, reducing airborne dust and minimizing enclosure needs — ideal for spot work or confined areas. Ask us about our vacuum-blasting solutions and recommendations.

Practical Field Tips

- Use small, sealed hose ports instead of large cutouts to maintain enclosure integrity.

- Monitor dust accumulation inside — heavy dust load on sheeting can cause sagging or collapse.

- Provide adequate lighting and ensure easy, safe exits in case of emergency.

- Before teardown, mist containment walls with water to suppress dust.

- Dispose of contaminated materials properly, especially if hazardous coatings were removed.

Tear-Down and Post-Blast Cleanup

- Mist down containment surfaces before disassembly to reduce dust dispersion.

- Fold disposal sheeting inward to trap debris.

- Use HEPA vacuums for any residual dust.

- Follow hazardous-waste protocols when required.

You Might Also Like

- Dust Collector Sizing Guide

- Abrasive Recovery & Recycling Systems

- General Purpose Blast Rooms & Booths

- Choosing the Right Abrasive Media

Summary & Call-to-Action

A well-designed containment system is vital to meet environmental standards, protect workers, and ensure coating success. Whether you need simple tarping or full Class 1A containment, BlastOne supplies complete containment solutions—from sheeting and tarps to dust collectors and abrasive recovery systems.

Contact BlastOne today for design assistance, product selection, or on-site containment consultation.

My Account

My Account