Why use a portable blaster?

Not every job has good access – your job may be meters up a scaffold or through a narrow manhole. Not every job will be conducive to using a conventional abrasive blasting setup – an occupied building or an operational factory. For these challenging tasks, a BlastOne portable blaster can often make the undoable, doable. In addition to being used for corrosion control purposes, BlastOne portable blasters can assist with other tasks e.g., removal of coating for non-destructive testing, removal of coating prior to welding.

Common issues with portable blasters

The most common issue with portable blasters is the lack of productivity compared to conventional blasting systems. This needs to be taken into consideration when scoping a blasting project where portable blasting equipment is being considered for use. This may require scheduling multiple operators for a project, that if using conventional equipment, would have only required one blaster.

Nozzle life on portable blasters also needs to be kept in mind. They are only available in tungsten carbide which, if used to operating silicon nitride nozzles, may not provide expected nozzle life.

Important considerations when choosing the right portable blaster

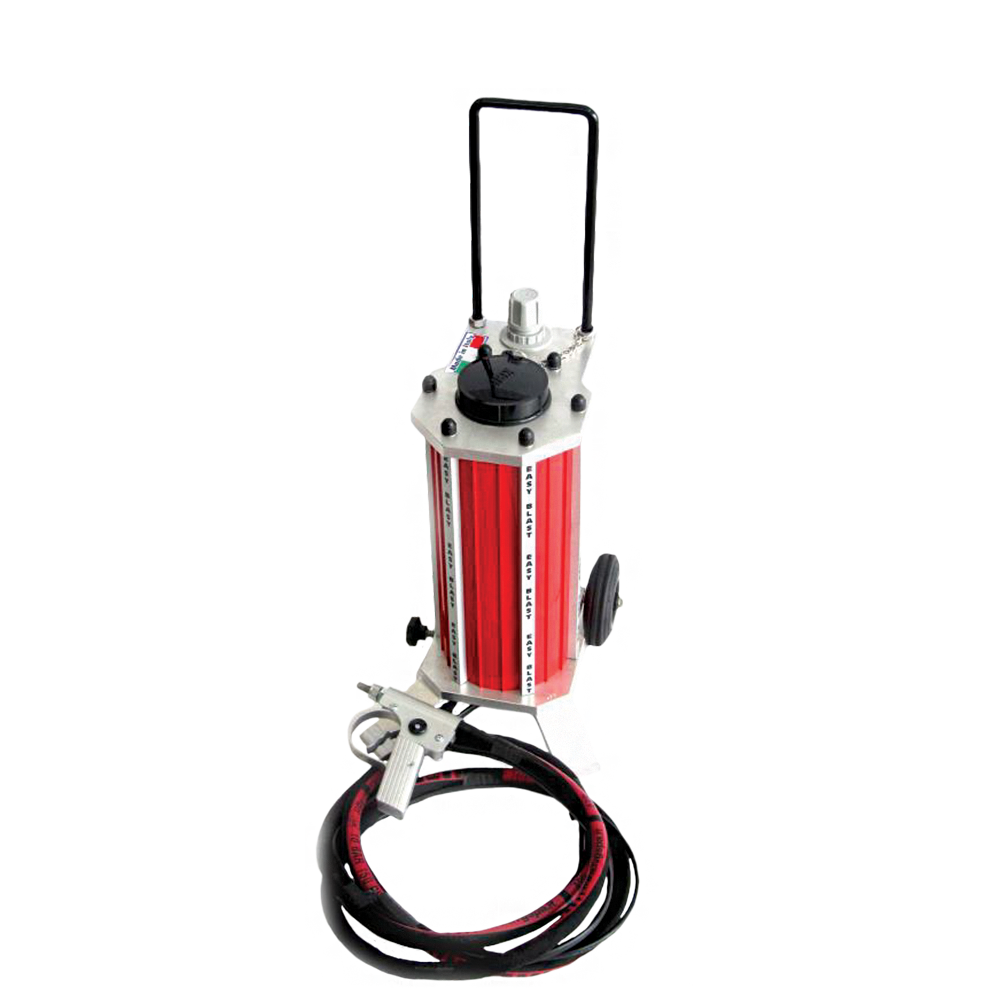

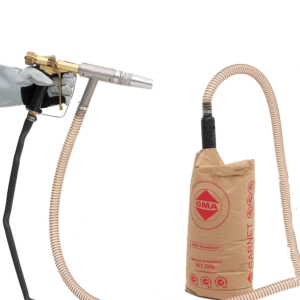

The main consideration in choosing a portable blaster is whether any lifting equipment e.g., crane or goods lift, is available to get the equipment to the work site. For example, the IBX25 blaster weighs 45 kg and if you fill it with a bag of garnet (25 kg) the combined weight is 70 kg. If this has to manually lifted, it is well in excess of safe carrying loads. In this instance it may be better to select the IBX6 unit or the Power Blast gun.

My Account

My Account