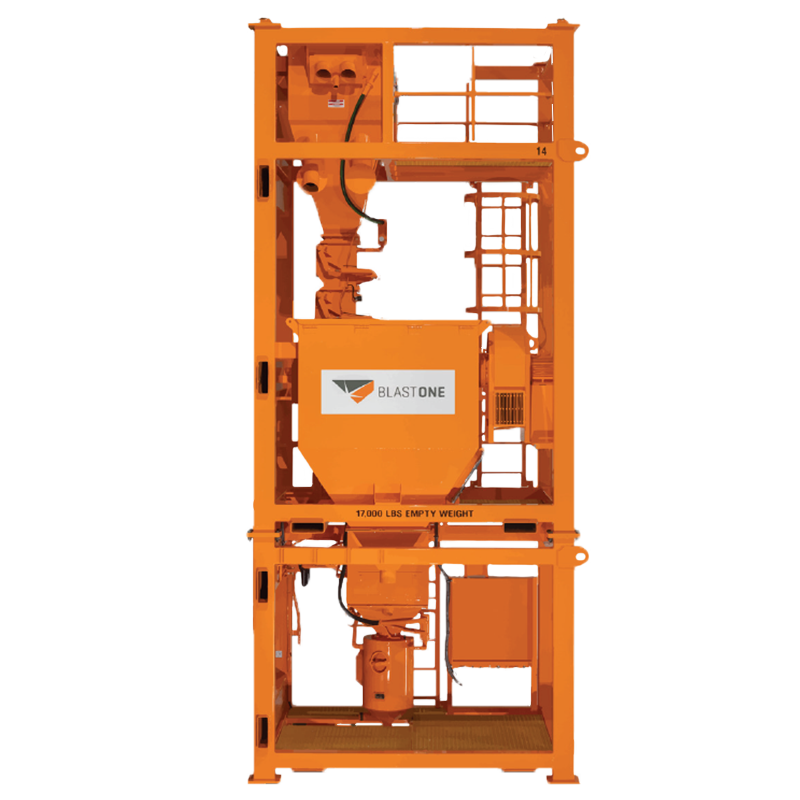

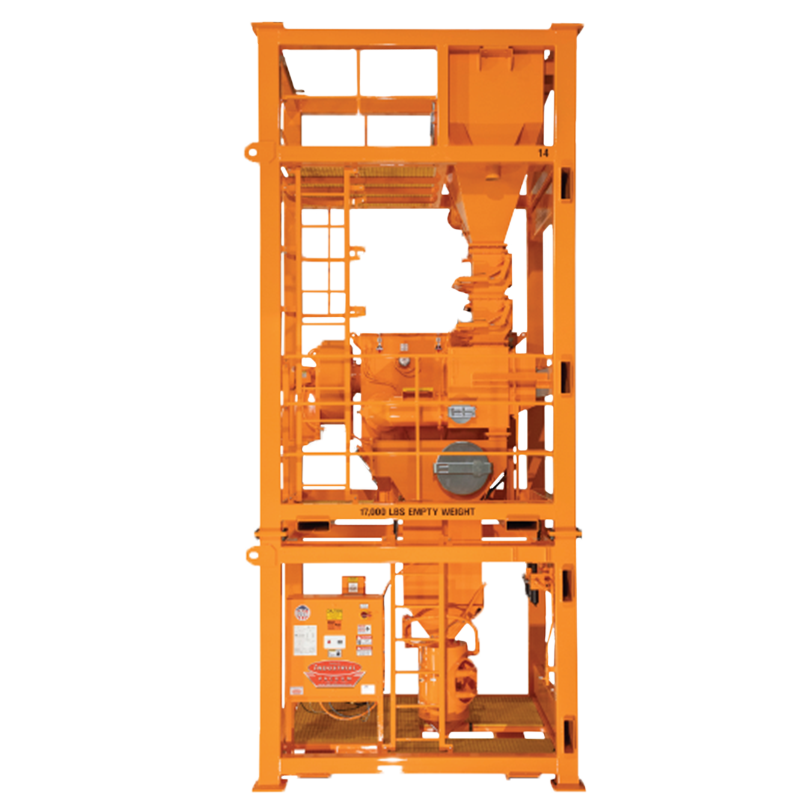

Hurricane Steel Grit Abrasive Recycler – Vacuum Powered

Sku: MKCOMBIS

Steel grit is a predominant abrasive used for abrasive blasting on large industrial projects like shipyards, blast rooms and oil tanks. A question often asked by contractors is whether they can recycle and reuse the steel grit to save on abrasive costs and disposal of spent abrasive. On blasting projects, having clean abrasive is paramount to the quality of surface preparation - any contaminants that are in abrasives will end up on your blasted surface.

The Hurricane Vacuum Recycler has the best cleaning capability of any portable or fixed installation recycler available on the market. This high-performance abrasive recycling system is an integrated vacuum recovery and automatic abrasive cleaning tower which can be used to clean both ferrous and non-ferrous abrasive.

Key Features

- Heavy-duty frame w/ both vertical and horizontal lifting eyes and fork pockets for easy transport and set-up

- Stainless steel panel housing controls for screens, on-board dust collector, magnetic drum, double-dump, and abrasive transfer unit

- (2) High-capacity 6” vacuum inlets for entry of recovered abrasive with 8” connection ports to vacuums(hoses not included)

- Reclaimed abrasive cleaning capacity of up to 50 tons per hour

- Adjustable abrasive air-wash w/ onboard dust collector for optimal cleaning

- Adjustable magnetic drum separator for fine-tuning of abrasive size

- Full-length hoses from the vibratory screens, air-wash, dust collector, and mag-drum carry all collected material to ground level for easy disposal

- Abrasive transfer unit designed to quickly, automatically, and efficiently transfer the clean abrasive to the blast unit or storage hopper

- Safety ladder and platforms for easy access to all components

My Account

My Account