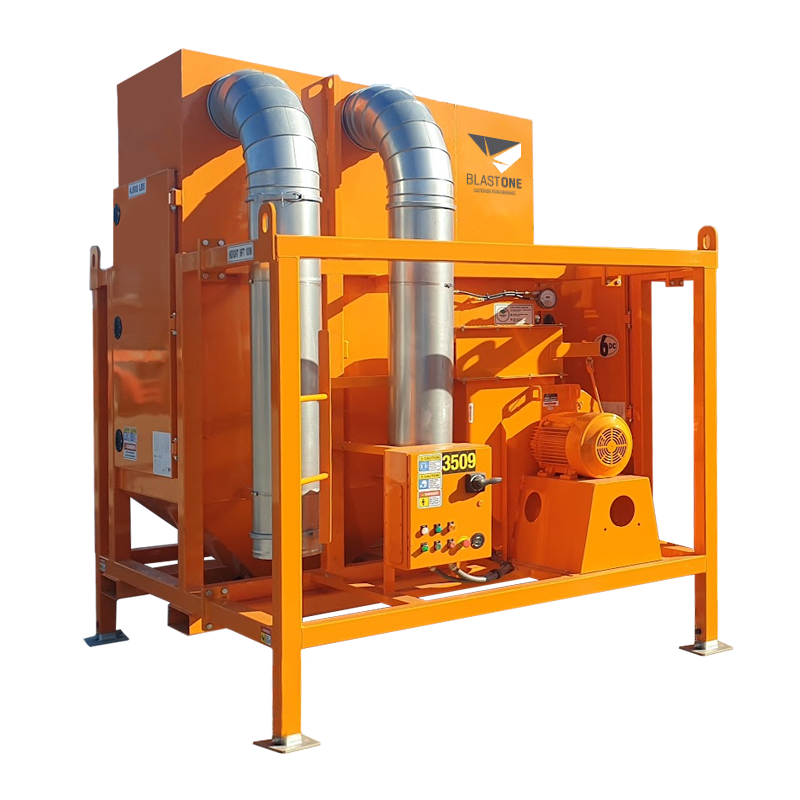

Mobile Diesel Dust Collectors for Sandblasting Projects – Rent or Purchase

Sku: P-DFDC

BlastOne mobile dust collectors are available from 6,000 cfm to 100,000 cfm. Power options include diesel or electric motors. KEY FEATURES BlastOne operates a large fleet of Mobile Dust Collectors and we manufacture our own units to suit. Obviously, because we own and operate our own dust collection units we build them to last! EASY FILTER ACCESS Ever had to replace filters on a mobile dust collector? It's a tough job right? Dirty filters are heavy, dusty, dirty... some portable dust collectors make it even worse by making you climb on top of the mobile dust collector to open an access door and have to vertically lift these filters onto the top of the unit. The poor mechanic! BlastOne portable dust collectors are a maintenance friendly design. Access to the filters is through the side of the unit. Most of them from ground level. The filters glide easily out of the unit and new ones slide right back in. HIGH PRESSURE FAN Do you ever need to run long lengths of duct hose, sometimes over 100ft? The ability to maintain high capacity whilst running long ducts is an important consideration for dust collector fan selection. A high pressure fan does this. Many mobile dust collector manufacturers over-rate their units. LONG FILTER LIFE THANKS TO SMART INTERNAL SPACING For ease of maintenance, filter replacement and filter life – BlastOne portable diesel dust collectors have an extra 30% space between the filters than other leading brand mobile dust collectors. This means far better dust release leading to longer filter life. SMART REVERSE PULSE To clean the filters, all BlastOne mobile dust collectors utilize a compressed air, reverse pulse blast to clean the dust cake from the filter cartridges. These are operated automatically when the unit is running. HOW DO MOBILE DUST COLLECTORS WORK? Dust laden air travels down the ductwork and enters into the dirty air inlet plenum at the rear of the dust collector. Here the heavier particles drop out of the air stream. The air is then drawn through a large bank of high efficiency filter cartridges where the dust is deposited on the outside of the filter cartridges. Filtered air passes through to the clean air plenum and passes through the fan blower to atmosphere. The cake of dust on the cartridges is dislodged continuously by an automatic reverse pulse jet. Disposal of the dust is via a hopper in the base of the dust collector. Clearance of the hopper is facilitated by a screw conveyor to an external waste container. This applies to most Onsite Dust Collectors & Industrial Portable Dust Collectors MOBILE DUST COLLECTOR OPTIONS BI-POWERED ENGINE (DIESEL/ELECTRIC) Some job sites are different to others. Contractors know that they can save a lot of money when the job-site has power available. That is why BlastOne offers a bi-powered dust collector. Run it on plant power, generator power, or use the inbuilt diesel engine – your job, your choice. SKID BASE The most cost effective option for a mobile dust collector is to mount it on a skid base. Movement onsite is possible with a large forklift or crane. This option is good for projects which have a long duration and the unit is relatively stationary. The skid has fork pockets, rigging mounts and extendable/ collapsible legs to make transportation easy. YARD TOWABLE TRAILER The next step up in mobility – if you have a long project duration (2+ months), the yard towable trailer gives the ultimate site portability. Delivery to site will be on a trailer, however, once onsite it can be towed as required. The ultra-heavy duty wheels & axles will last you many years of hard service. HIGHWAY TOWABLE TRAILER The ultimate in mobility. Perfect for projects that are short in duration (under 2 months). The highway towable trailer means that the dust collection system and power/fan unit are all mounted on a highway certified trailer meaning that the unit can be moved anywhere at any time. ENGINE CANOPY As supplied, the base dust collector has an engine which is not enclosed. Some customers prefer to have the diesel engine enclosed within a canopy for security. This is a simple add on module that BlastOne can provide. ACOUSTIC ENGINE CANOPY AND FAN ATTENUATOR For the contractors who have to do work in noise sensitive environments, BlastOne can provide a full sound attenuation enclosure around the diesel engine and fan of the mobile dust collector ACOUSTIC LINED FILTER HOUSING AND PULSE VALVES As a further option for noise reduction, the filter housing and pulse-valves can be fitted with an acoustic lining. This reduces the operating noise to below 69 dB at 50 feet. ECO-CLEAN™ ON-DEMAND CARTRIDGE CLEANING Upgrade the filter cartridge cleaning system to a system that only pulses when it needs to. This increases the filter life and reduces compressed air requirements. The system monitors the filter cleanliness and only pulses the filters when required. ULTRA-WEB II FILTER CARTRIDGES For the ultimate filter life, get your dust collector with Ultra- Web II filters. These Teflon lined filter cartridges will last up to 70% longer than the standard cartridges supplied in the base dust collector. CLIENT TESTIMONIAL "I have been using BlastOne's portable mobile dust extractors on my projects every day for over 10 years and have only changed the filters out 3 times." – BRIDGE SUPERINTENDENT, SYDNEY, AUSTRALIA Industrial dust collectors are an integral part of your abrasive blasting project, used to extract, capture or collect airborne dust from the abrasive or sand blasting process. Blastone mobile or stationary dust collectors and air scrubbers are available for hazardous & non-hazardous ducts, including lead, zinc, & chromates, common found in the removal of old paint coatings. Dust extraction & collection for lead abatement projects. Mobile dust collectors are also ideal for tunneling projects - to collect airborne silica dust. Additional activated carbon banks & HEPA filtration is also available for defuming in soil remediation projects. My Account

My Account