Multi-Media Blasters for Versatile Abrasive Use

Why Multi-Media Blasting Matters

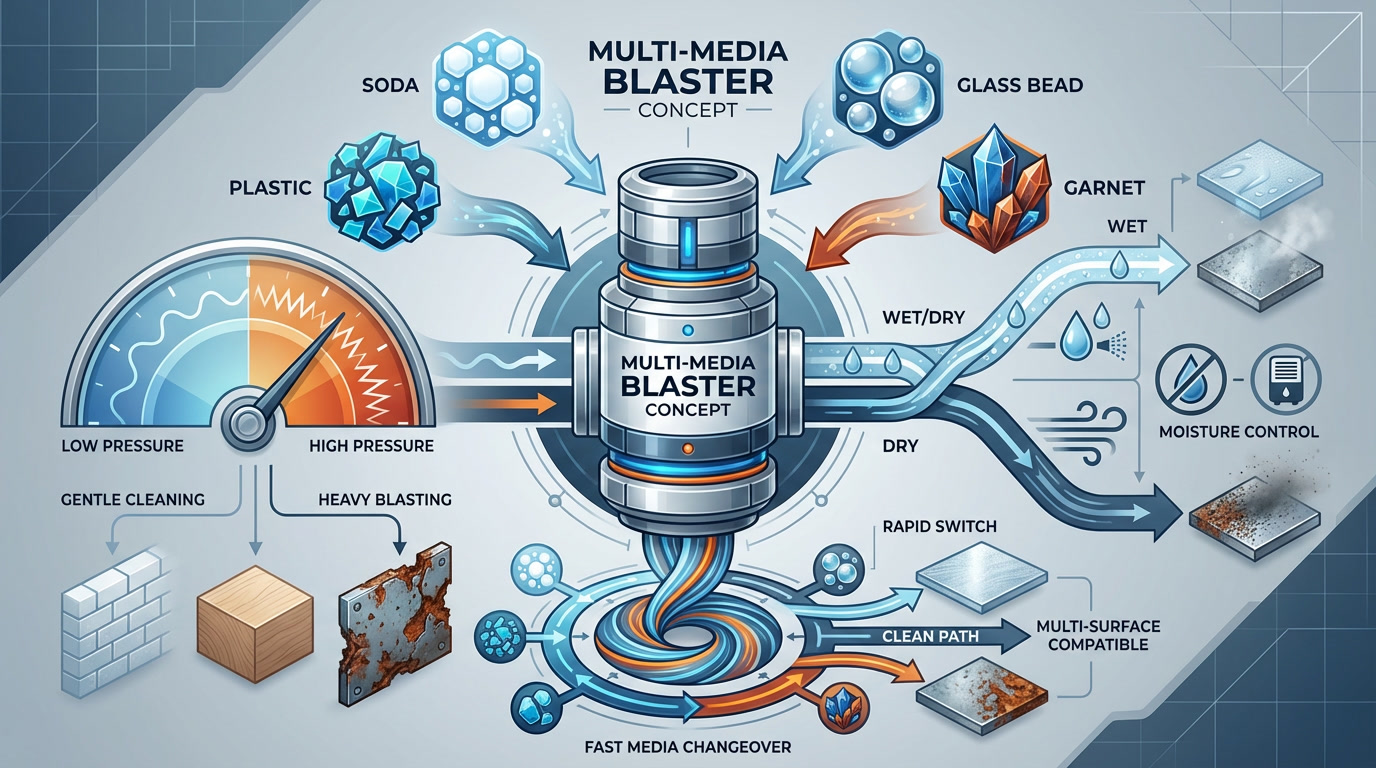

If your work spans delicate restoration one day and heavy rust removal the next, a single-purpose blast pot slows you down. Multi-media blasters let you switch from gentle media like baking soda or corn cob to standard grits like garnet—often in minutes—so you can handle more jobs with one rig and one crew.

What Is a Multi-Media Blaster?

Multi-media blasters are engineered to run a wide spectrum of abrasives and to operate across low and high pressures. Compared to traditional high-pressure pots optimized for expendable mineral media, multi-media systems also support low-pressure precision blasting, wet/dustless blasting, and quick media changeovers—without swapping to a dedicated soda pot or a separate wet-blast unit.

Ideal Applications

- Historic restoration & conservation: Low-pressure soda or corn cob to clean wood, stone, or statues; fine garnet for steel brackets afterward.

- Facilities & MRO: Degrease and clean machinery with soft media; switch to grit for corrosion on pipes and frames.

- Mobile contractors: One trailer-mounted solution for graffiti removal, automotive panels, tanks, bridges, and shipyards.

Key Features (What to Look For)

1) Precision Abrasive Metering

Valves like Thompson II abrasive metering valve or TerraValve® XL provide a wide, repeatable adjustment range—from a trickle feed for soda to full-bore grit. This is critical for consistent results and reduced media consumption.

2) Wide Pressure Range (Gentle to Aggressive)

Integrated regulators let you blast at 15–30 psi for fragile substrates—or dial up to 100+ psi for heavy scale. Being able to tune pressure on the fly is what makes a single rig truly “multi-media.”

3) Media Agitation & Flow Aids

Lightweight media tends to bridge. Vibrators or agitators on the pot cone keep soda, plastic, and organic media flowing, preventing clogs and downtime.

4) Fast Clean-Out & Media Switching

Quick-dump ports, clean-out access, and separate air/media shutoffs allow rapid changeovers. Blow out the line, empty remaining media, load the next abrasive, confirm settings, and go.

5) Wet / Dustless Blasting

Many units include or support water-injection options. See wet-blast injection kit options and AmphiBlast™ wet/dry systems.

6) Full-Bypass Capability for Heavy Grit

On larger models, a full-port bypass lets you operate like a standard high-production pot when you want maximum throughput with garnet or steel shot.

How to Use a Multi-Media Blaster (Two Real-World Setups)

A) Delicate Aluminum with Baking Soda

- Set pressure ~30 psi.

- Fit a small, smooth-bore nozzle (e.g., 3/16″).

- Lean media mix (air-rich).

- Ensure vibrator is on for consistent feed.

- Keep air dry; soda is hygroscopic.

B) Heavily Rusted Steel with Garnet

- Dump residual soda, blow out lines.

- Load fine-to-medium garnet; increase pressure to 90–110 psi.

- Open metering gradually until cutting is efficient without wasting grit.

- If equipped, use bypass mode for higher flow.

Special Considerations for Soda & Lightweight Media

Differential pressure control above/below the metering point keeps ultra-light media feeding under low resistance.

Dry air is essential (use after-coolers, moisture separators, or air dryers). See compressed air dryers & moisture separators.

Use appropriate strainers/screens and short, uncluttered hose runs to limit hang-ups.

Thoroughly clean out before switching to grit; cross-contamination can clog small nozzles or affect surface results.

Benefits You’ll Notice

- One rig, more jobs: Tackle restoration, industrial, and municipal work with a single machine.

- Higher utilization & ROI: Fewer idle assets, fewer specialized pots.

- Faster multi-step workflows: Clean with soda, then profile with garnet—no equipment swap.

- Smaller footprint: Free up truck/trailer space for compressors, containment, or dehumidifiers.

Limitations to Weigh

- Higher upfront cost & complexity: More valves and regulators to maintain.

- Changeover time: Allocate minutes for dump/blow-down and setup; train operators to avoid mixing media.

- Over-spec for single-purpose shops: If you exclusively blast heavy steel, a simpler pot may be more economical.

Popular System Examples

- Schmidt® M-Series (Mini, M-11, M-21, M-31): Multi-media capable, with precision metering (Thompson II or TerraValve options) and wet injection support. Schmidt® M-Series Multi-Media Blasters

- AMphiBlast® / MistBlaster® systems: Dry-to-wet switching with support for fine media. Explore wet/dry pots

Selecting the Right Multi-Media Package

Step 1: Define Your Media Range

Soda/plastic only? Or soda to garnet/steel? Choose valves and agitation accordingly.

Step 2: Match Air Supply & Nozzle

Confirm CFM and pressure at the nozzle. Select nozzle size to fit your compressor’s true output. Air compressor sizing calculator | Blast nozzles for soda and grit

Step 3: Plan Moisture Control

Hygroscopic media demands compressed air dryers & moisture separators.

Step 4: Decide on Wet-Blast Needs

If dust regulations or substrate cooling matter, consider a wet-blast injection kit or a wet/dry system and compatible hoses.

Step 5: Accessory Bundle

Add hoses, deadman controls, screens, PPE, containment, and, if necessary, jobsite dehumidifiers and containment sheeting for “hold-the-blast.”

Pro Tips from the Field

- Start lean on media feed; add gradually until cutting is efficient.

- For soft substrates, increase standoff distance and reduce angle of attack.

- Keep hose runs short, with minimal bends.

- Log your repeatable settings (pressure, feed, nozzle) per media and surface.

Troubleshooting Quick Guide

- Pulsing flow (soda): Check air dryness, open vibrator, reduce back-pressure, verify metering gap.

- Weak cutting (grit): Check compressor output at nozzle, look for pressure drop, step up nozzle size if air allows.

- Frequent clogs: Confirm screen condition, remove moisture, inspect for media mix/cross-contamination.

Safety & Compliance

Use appropriate PPE and follow containment best practices. Wet blasting can reduce airborne dust; verify local regulations and media disposal requirements, especially for coatings containing heavy metals.

Recommended BlastOne® Products & Internal Links

- Schmidt® M-Series Multi-Media Blasters

- Thompson II abrasive metering valve

- TerraValve® XL

- Wet-blast injection kit

- ARMEX® soda blasting media

- Blast nozzles for soda and grit

- Compressed air dryers & moisture separators

- Contractor air compressors for blasting

- Containment sheeting & jobsite dehumidifiers

- Blasting best practices & training

Related Guides (You Might Also Like)

- Soda Blasting: When to Use It and How to Set Up

- Wet/Dustless Blasting vs Dry Blasting: Choosing the Right Method

- Moisture in Compressed Air: Causes & Solutions

- Blast Nozzle Selection & Care

FAQs

Can I run both soda and garnet through the same machine?

Yes—multi-media blasters are designed for this. Always clean out thoroughly before switching to prevent clogs and inconsistent results.

What pressure should I use for fragile substrates?

Start around 15–30 psi with a small, smooth-bore nozzle, and test on a hidden area.

Do I need a wet-blast kit?

If dust control, substrate cooling, or compliance are priorities, it’s a smart add-on. You can switch back to dry at any time.

How big should my compressor be?

Match compressor CFM and pressure at the nozzle to your largest planned nozzle size. We can help you size the system.

Is soda safe for concrete and brick?

Typically yes at low pressure, but test first; older or soft brick may need ultra-low pressure and wider standoff.

Call to Action

Ready to quote a multi-media package? Talk to a BlastOne specialist about your media mix, compressor, and typical substrates. We’ll spec the pot, valves, hoses, moisture control, and training you need to win more jobs with one rig.

My Account

My Account