Nozzle Wear Size Analyzer Gauge

Sku: INH131PBAG

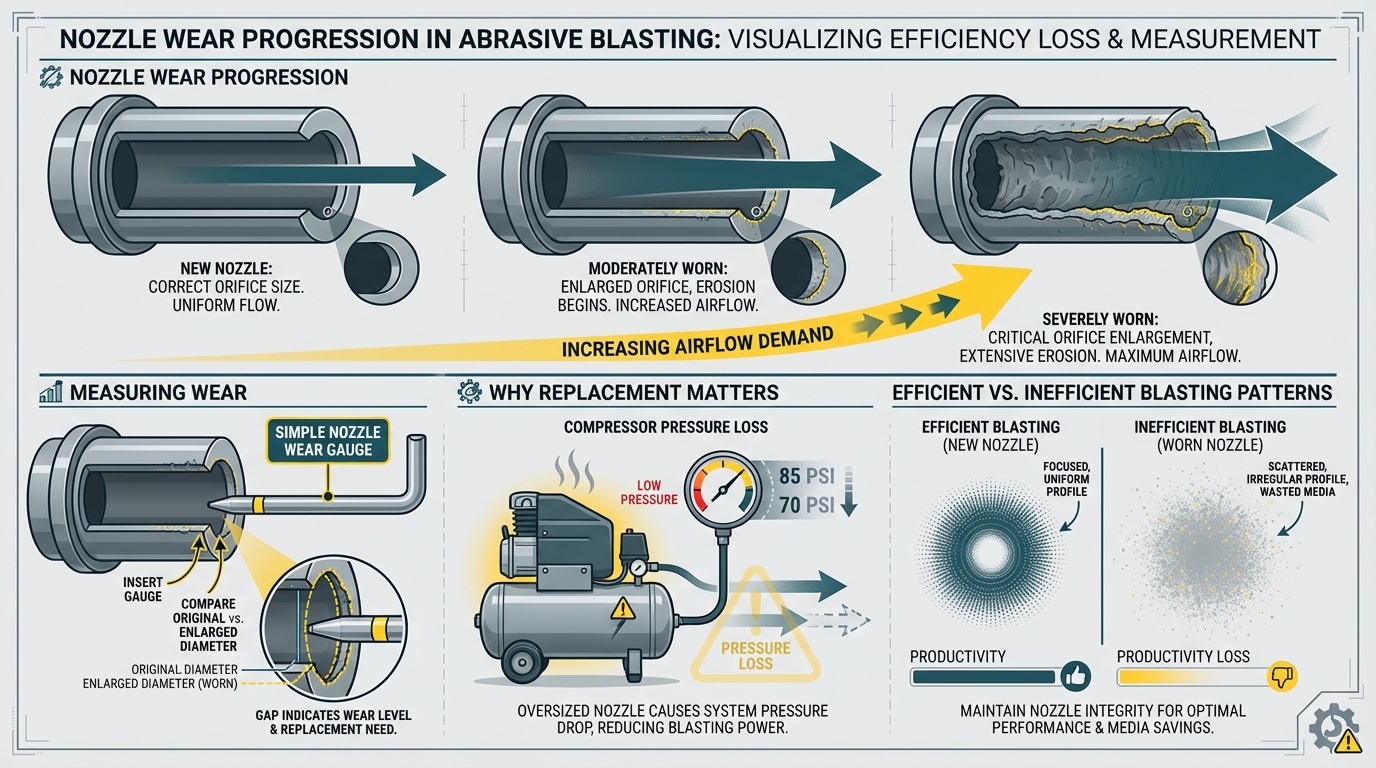

Maximize Your Blasting Efficiency with the Blast Nozzle Wear Size Analyzer Gauge. Over time, blast nozzles undergo wear, which can significantly impact the efficiency of your blasting process. The Blast Nozzle Wear Size Analyzer Gauge is meticulously designed to help you quickly determine the level of wear in your nozzle and its internal diameter. Key Features:- Easy Analysis: Instantly measure the internal diameter of the blast nozzle orifice.

- Wear Level Detection: Accurately determine the wear level of your nozzle, ensuring efficient performance.

- Size Markings: Clear size markings provide quick insight into your nozzle's size.

- Comprehensive Kit: Includes a removable cap and crayon for precise measurement.

- Sold Individually: Each gauge is sold separately for your convenience.

- Increased air requirement due to the enlarged orifice, leading to inefficiencies.

- Uneven spread of abrasive across the blast pattern, reducing quality.

My Account

My Account