Blast Nozzle Care & Wear: Maximizing Nozzle Life

Why Nozzle Care Matters

- The blast nozzle determines your blasting power, efficiency, and surface quality.

- A worn nozzle increases air consumption, lowers pressure, slows production, and wastes media.

- Proper care maintains consistent performance and extends lifespan.

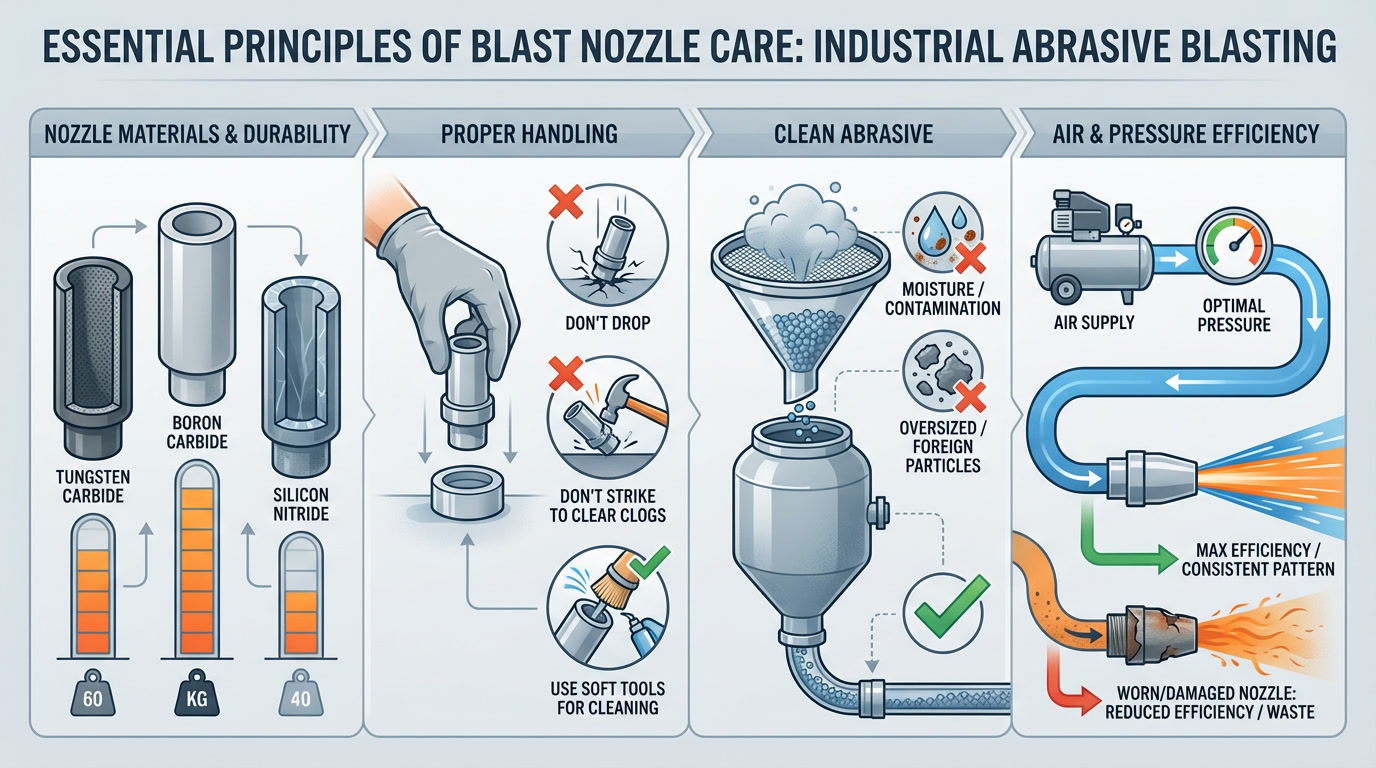

Nozzle Materials and Durability

- Tungsten Carbide: Long-lasting, ideal for garnet, steel grit, and slag. Example:

TVP Tungsten Carbide Blast Nozzle. - Boron Carbide: 3–5× longer life than tungsten; best for aluminum oxide and silicon carbide.

Curved Boron Carbide Blast Nozzle. - Silicon Nitride: Long life, lightweight, impact-resistant.

Ultra-Tuff SiNi Blast Nozzle.

Proper Handling and Care

- Never strike a nozzle on steel to clear clogs.

- Use a wooden dowel or soft rod to gently remove blockages.

- Strain abrasive before loading to prevent debris damage.

- Use polyurethane-jacketed nozzles for added shock protection.

- Cap the nozzle tip when not in use and avoid dragging it by the hose.

- See lightweight shock-resistant option:

Ultra-Tuff Silicon Nitride Nozzle.

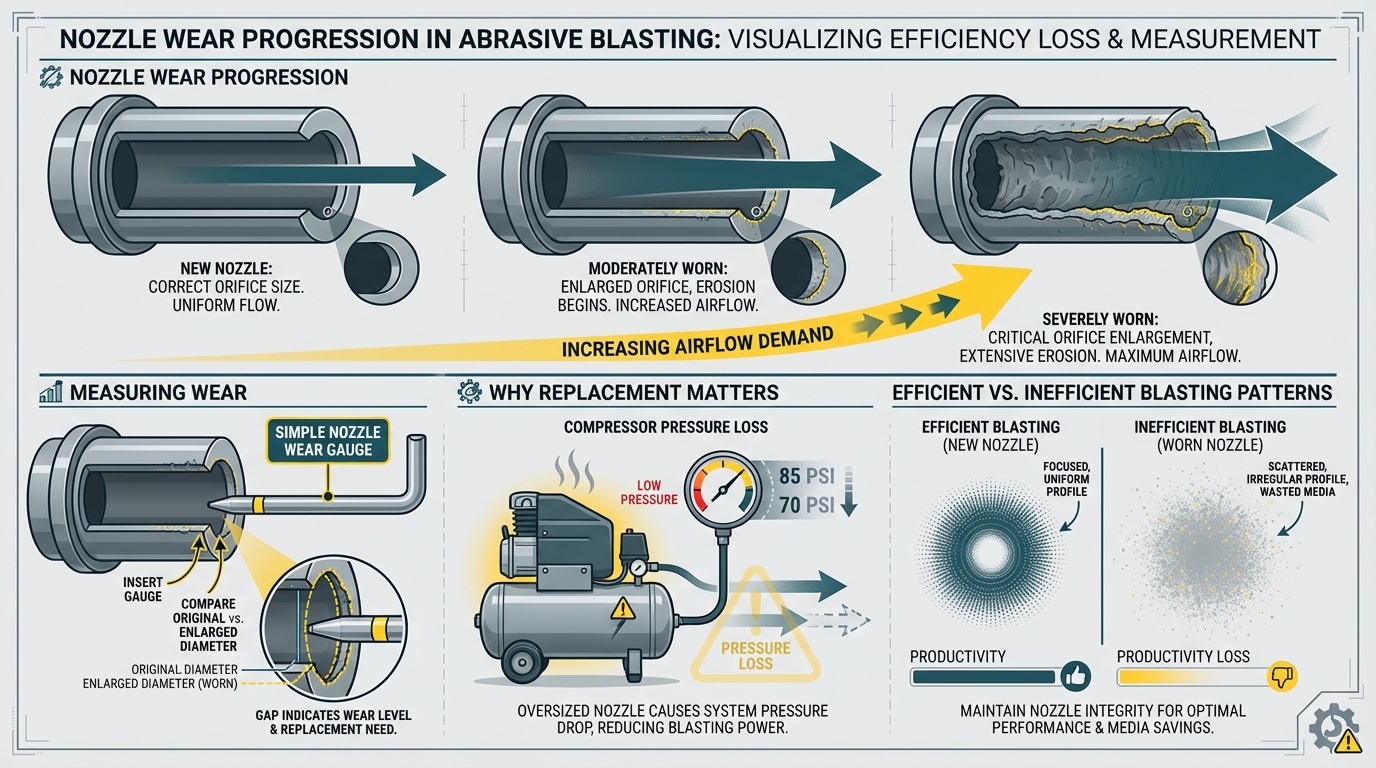

Recognizing and Measuring Nozzle Wear

- Nozzles gradually enlarge from abrasive erosion.

- Replace the nozzle when the orifice grows by approximately 1/32 inch (0.8 mm).

- Visual inspection is unreliable—use a wear gauge.

- Tool: Nozzle Wear Gauge.

- Increased compressor load or falling pressure indicates nozzle enlargement.

Effects of Wear on Performance

- Larger orifice size increases air demand and can drop pressure significantly.

- Every 1 psi lost equates to approximately 1.5% productivity loss.

- Lower abrasive velocity increases media waste and accelerates hose wear.

Proper Sizing

- Use the largest nozzle your compressor can supply at around 100 psi at the nozzle.

- If pressure cannot be maintained, downsize the nozzle rather than overloading the compressor.

- Reference: Blast Nozzle Buying Guide.

Clean, Dry Abrasive

- Moist or contaminated abrasive clumps and can cause liner damage or blockages.

- Use moisture separators and air dryers to ensure clean abrasive flow.

- Screen abrasive during loading to prevent oversize debris entering the blast pot.

- Related info: AirPrep Moisture Removal Guide.

Correct Technique

- Maintain a 6–12 inch standoff distance for optimal performance.

- Too close: increased ricochet and potential liner damage.

- Too far: increased dust ingestion leading to accelerated wear.

- Ensure correct hose sizing: Blast Hose Sizing Guide.

Temperature and Rotation

- Nozzles can heat from continuous blasting; allow cooling breaks.

- Rotate between two nozzles to extend service life.

When to Replace

- Replace when orifice size is 1/32 inch over its original diameter.

- Replace if cracks, chips, or unusual air patterns appear.

- Replace worn gaskets to avoid thread wear and leaks:

Nozzle Gaskets.

Selecting the Right Nozzle for the Job

| Abrasive Type | Recommended Liner | Example Product |

|---|---|---|

| Garnet / Steel Grit | Tungsten Carbide | TVP Tungsten Carbide Venturi |

| Aluminum Oxide / Silicon Carbide | Boron Carbide | Boron Carbide Curved Nozzle |

| Coal Slag / Glass Bead / General Use | Silicon Nitride | Ultra-Tuff SiNi Nozzle |

- Full comparison chart: BlastOne Nozzle Selection Guide.

Innovation Spotlight: Low-Noise Nozzles

- Low-noise nozzles significantly reduce sound levels and recoil force.

- Example: SnakeBite XQ Silenced Nozzle.

- See additional options:

Silenced Nozzles.

Storage Tips

- Blow out abrasive before storing nozzles.

- Store in a padded box or wrapped in cloth.

- Use a rubber tip cap to prevent impact damage.

My Account

My Account