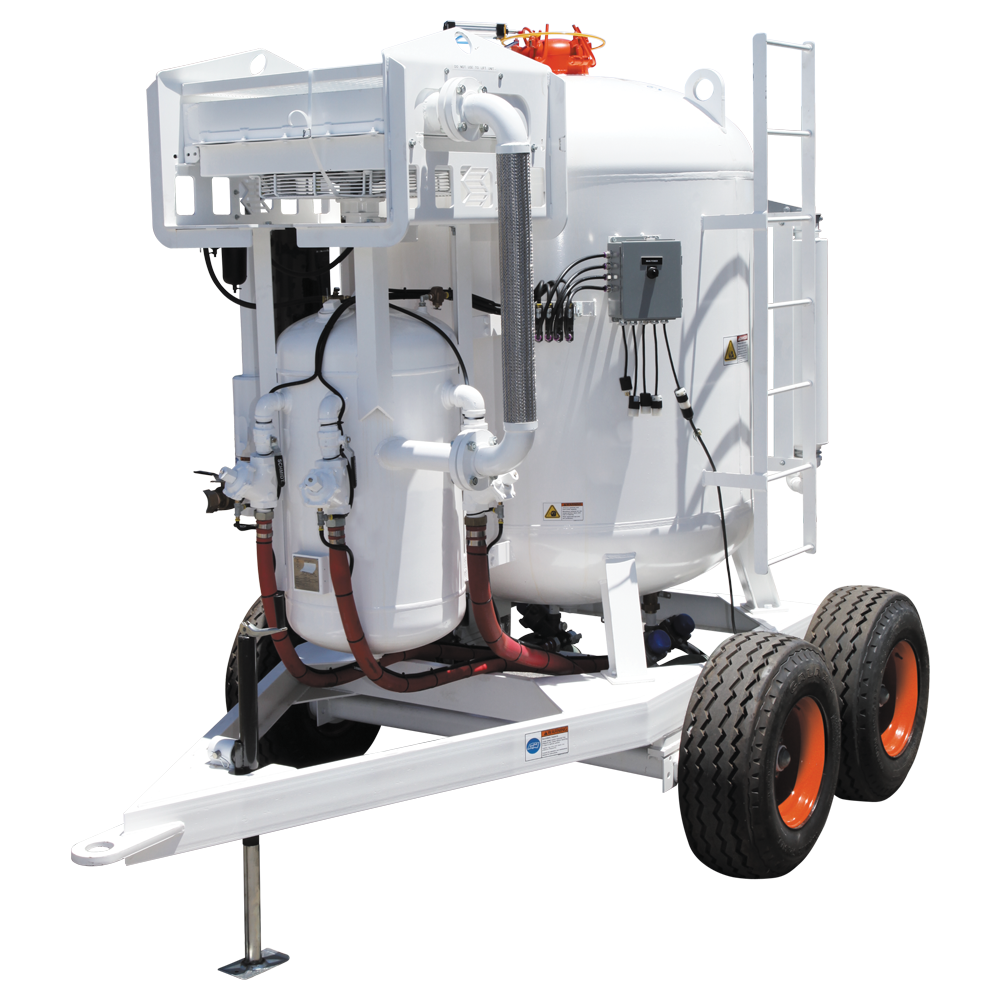

Schmidt Hybrid Bulk Blast Machine with built-in AirPrep™

Sku: BMS1602TVH1600

The Schmidt® 160cf Hybrid Bulk Blaster (aka Hybrid SupaMega) with AirPrep™ Air Dryer delivers maximum blasting efficiency with unmatched convenience. By integrating the trusted performance of Schmidt bulk blasting technology and the proven AirPrep™ moisture-removal system into one unit, this hybrid design eliminates the need for a separate air dryer, storage rack, and additional hoses. The result is a streamlined, compact, and fully integrated blasting system that saves time and space while improving overall productivity.

With a built-in deliquescent AirPrep™ air dryer, the hybrid system removes moisture before it reaches the vessel, keeping abrasive media dry and flowing smoothly. This helps prevent clogs, reduces wear on valves, and improves coating adhesion. The reduced air hose requirements also minimizes pressure loss for stronger, more consistent blast performance.

This 160cf Schmidt® MegaBlaster is shown with dual Thompson® Valve II controls, but the setup can be customized with TeraValve™ XL™ controls, different vessel sizes, and mount options including skid, yard trailer, or highway trailer configurations. Like all Schmidt bulk blasters, it features a HALOK® closure safety system, CEN blowdown, 3-inch flanged cleanout, and Ergo-Ladder® access for safe, efficient operation.

By integrating the air dryer directly into the bulk blaster, Axxiom has created a low-maintenance, compact system that reduces jobsite clutter, saves setup time, and simplifies handling and transport—all while delivering the same performance Schmidt users expect.

- Integrated AirPrep™ air dryer eliminates need for separate dryer setup

- Reduces hose length, storage space, and jobsite footprint

- Removes moisture for consistent media flow and better surface prep

- Extremely low pressure loss increases blasting efficiency

- Fully customizable vessel size, valves, and mount configuration

Includes HALOK® closure, CEN low-noise blowdown muffler system, and 3" flanged cleanout

- Ideal for contractors needing a single, portable, moisture-free blasting system

My Account

My Account