Abrasive Blasting Metering Valves & Parts

The heart of any blast pot is the abrasive metering valve, which acts as the regulator to feed the blasting abrasive into the high pressure & high velocity compressed air stream. Regardless of the media type, money can be saved if your metering valve has fine-adjustment control. Too much abrasive will flood the airstream – this can actually slow down the blasting operation – as well as waste media. Too little abrasive will starve the compressed air stream, and slow production as well. Setting the abrasive metering valve precisely is imperative for high production abrasive blasting operations. BlastOne has represented the Schmidt by Axxiom Manufacturing line of metering valves for decades. Schmidt valves became the benchmark when they released the Thompson valve years ago, and have continued their tradition of innovation with the TeraValve and MicroValve III. These valves come in a variety of configurations and all set the standard for precision abrasive metering.

Showing 1–15 of 43 results

-

The Axxiom TeraValve - the next generation abrasive metering valve for blast machines with pressure-hold technology. Featuring:

- Extended Life. Schmidt XL technology utilizes tough metal alloys and internal wipers, reducing premature wear due to dust migration.

- Easy Interchangeability. Customers with older Thompson valves that need rebuilt have an easy alternative. Exchange the old valve with a new TeraValve with no modifications required!

- Efficient. Pressure-hold design maintains pressure in the pot, even with deadman released. This can save up to 15% of abrasive when your projects involve a lot of start-stop blasting. Reduces expensive compressed air consumption too!

- Economical. The compact design of the TeraValve actually costs less than the previous-gen Thompson II valve.

- Available for more applications. Pressure-release pots with limited clearance (where traditional Thompson Valves do not fit) can also benefit. Efficient pressure-hold technology can be used on any blast pot with a minimum of 6" clearance by installing a TeraValve retrofit kit.

- Genuine Parts - Manufactured by Schmidt® / Axxiom Manufacturing

Note: Diaphragm-activated piston requires minimum of 75 psi control pressure

-

When Axxiom released the Thompson 2 valve, the benefits of Pressure-Hold technology were instantly upgraded by improved user experience over the Thompson I valve. Details as follows:

- Improved servicability:

- Body and cylinder are now 2 parts, providing easier removal of sleeve and plunger.

- Additional Seal protection:

- Has 3 separate seals (versus the original 1), reducing dust migration and improving durability.

- Multiple Sleeve choices:

- In addition to the original Tungsten Carbide and Urethane full-flow options, Axxiom has released additional options that help prevent over-consumption in various applications.

- Virtual Position Indicator:

- Simplifies setting of the media flow rate.

- Cleanout:

- Full 1" port directly under the inlet allows cleanout without removing the valve.

- Size info:

- Standard 1-¼” (32 mm) inlet thread

- 4 choices of MNPT piping for pusher-line connection

- 1", 1-¼", 1-½", and 2"

- Options: Make servicing the valve even more convenient with one of the following:

- Union-End Ball Valve - The UEBV allows removal of valve without emptying the pot.

- Tri-Clover Quick Connect - allows removal of valve without tools.

- Combination UEBV and Tri-Clover - combines the benefits of both options at a reduced cost.

Meter your abrasive efficiently and conveniently with the genuine Axxiom Thompson II valve!

- Improved servicability:

-

- Pressure-release deadman control valve i.e., blast machine depressurizes when the deadman handle is released.

- Used when an overhead hopper automatically feeds abrasive into a blast machine.

- Rugged stainless steel body, compact, isolated 2-bolt construction.

- Doubles blast machine refill cycle time.

- Virtual Position Indicator illustrates orifice size, giving the ability to set abrasive flow quickly and consistently.

- Set and forget – flow rates stay set where you put them.

- High wear, rugged plunger seal.

- Stainless steel body for long life.

- Improved urethane clean-out port enabling quick removal of obstructions while improving port and valve life.

- Fit a rebuild kit while the valve is still fitted to the blast machine.

- Sold individually.

- Genuine Products – Manufactured by Schmidt / Axxiom Manufacturing

-

Enhance your blasting efficiency with the Schmidt® MicroValve Abrasive Metering Valve (SKU: P-GV2125). Designed for precise abrasive flow, this rugged valve ensures optimal sandblasting media use.

- The MicroValve™ changed the industry by providing accurate metering valve

- Simple screw type metering through a low-wearing valve

- 1 ¼" (32 mm) thread abrasive inlet port

- Hardened steel threaded base nipple

- Sold Individually, Brass Coupling not included

- Genuine Products - Manufactured by Schmidt® / Axxiom Manufacturing

-

- Thompson Metering Valve II lasts up to 10 times longer than any other valve, due to its unique engineering

- Designed to handle the harshest blasting environments known

- Will handle up to a 3/4" blast nozzle

- Will work with any abrasive, including very fine/dusty abrasives

- Most rugged and reliable valve for any application

- Sold Individually

- Genuine Parts - Made in USA by Schmidt / Axxiom Manufacturing

-

The Thompson I Valve was invented by Bob Schmidt and was instrumental in causing the popularity of pressure hold technology.

- Pressure-hold systems retain the pressure in the blast pot until the deadman handle is depressed. This reduces abrasive and energy waste.

- The Thompson I offers fine control for abrasive metering

- It comes in 3 nipple size configurations:

- 1 ¼” (32 mm) x 1 ¼” (32 mm)

- 1 ½" (38 mm) x 1 ½" (38 mm)

- 2" (50 mm) x 2" (50 mm)

- Threaded-plunger metering design with air actuated operation

- Fits most sand blast hoppers, blast pots or abrasive blasting machines

- Genuine Parts - Manufactured by Schmidt® / Axxiom Manufacturing

Note: The Thompson I valve, while still available, has become less common. The more modern Thompson II valve or state-of-the-art TeraValve are more popular and can replace the Thompson I without any modifications.

-

The Flat Sand Valve is legacy metering technology, where the metering is performed by sliding a lever to open and close the abrasive port. It is simple in design and relatively inexpensive, but has a few limitations. Details as follows:

- Slide-plate metering design, controlled by lever

- 1 1/4" (32 mm) ports

- Features side cleanout-inspection port

- Available with or without outlet nipple and Y-piece (Optional rubber lined nipple is available to extend nipple life.)

- The major limitations are:

- Not recommended for use with metallic abrasives

- The slide plate/lever design does not provide effective fine metering control. Typically this results in over consumption of media. For low-volume blasting using inexpensive media, this may not be an issue.

Note: These limitations can be eliminated by replacing the FSV with a MicroValve 3. No modifications required. Alternatively, legacy pots with inlet-outlet controls and FSV technology can be completely modernized with either the MicroValve Retrofit Kit (for pressure-release technology) or the TeraValve Retrofit Kit (for pressure-hold technology).

-

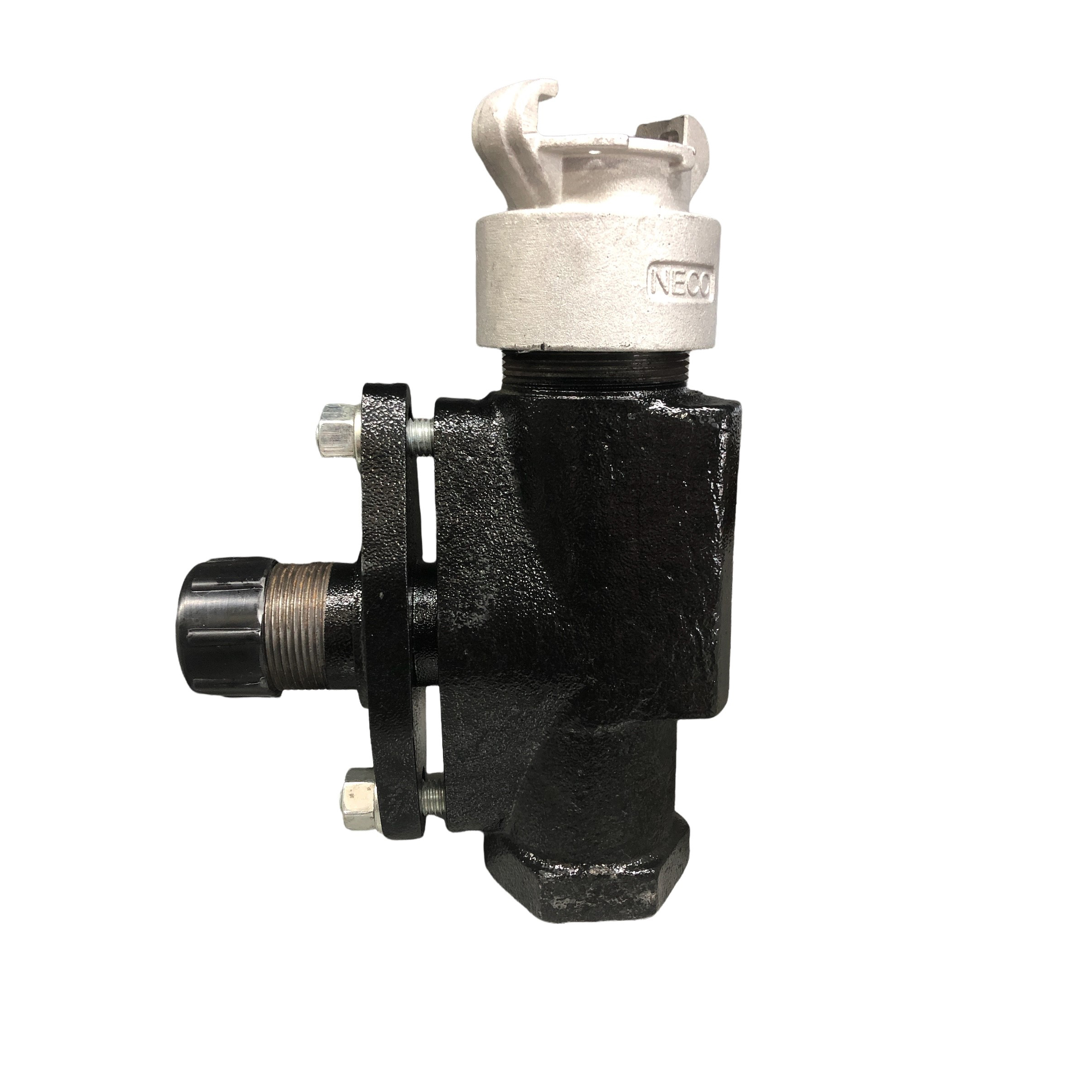

GVDNV100

- HFSTC3 blast coupling included

- Designed for use with coarse metallic abrasives

- Heavy cast iron construction

- Not recommended for use with fine abrasives

- 1 1/2" NPT female thread air connection

- Recommended upgrade: MicroValve 3

GVDNV100- HFSTC3 blast coupling included

- Designed for use with coarse metallic abrasives

- Heavy cast iron construction

- Not recommended for use with fine abrasives

- 1 1/2" NPT female thread air connection

- Recommended upgrade: MicroValve 3

-

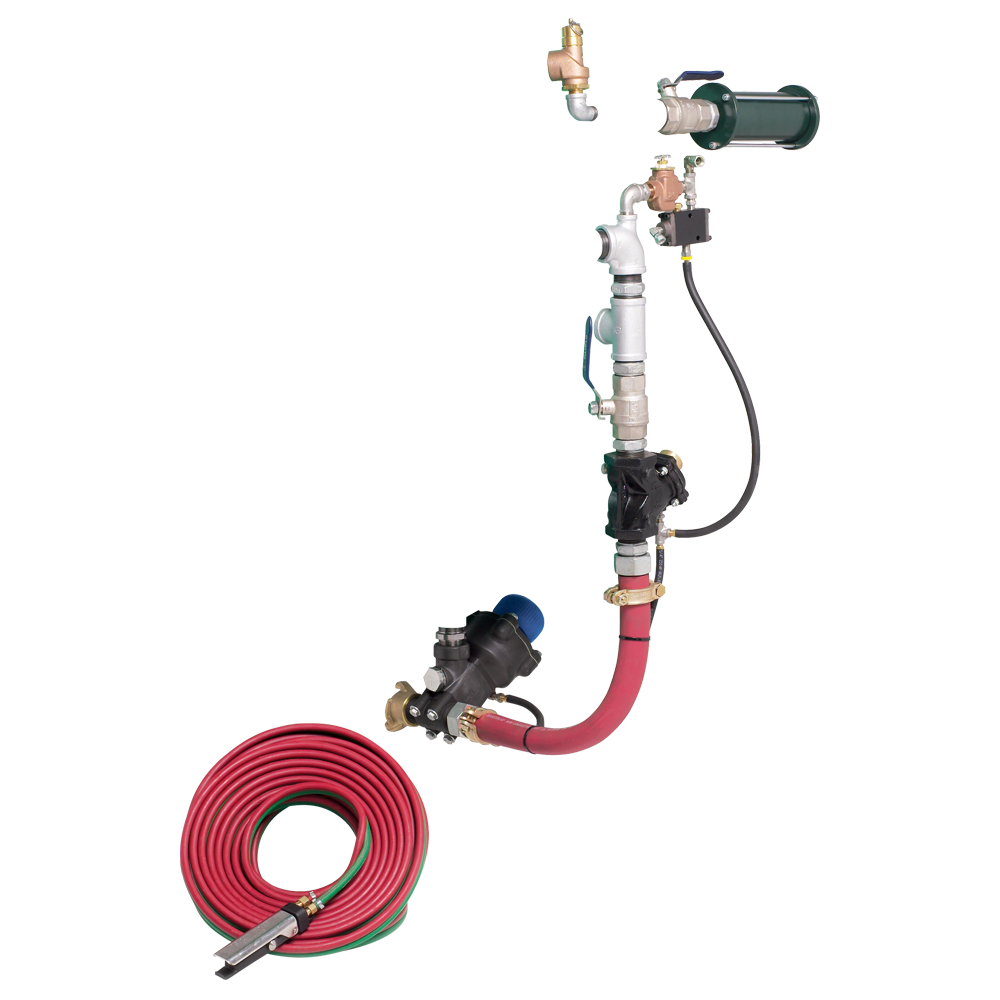

- TeraValve™ Complete Blast Pot Retrofit Kit

- Allows you to completely retrofit your existing blast pot into the latest pressure-hold technology

- Reduces abrasive consumption up to 15% compared to pressure-release systems, depending on application.

- TeraValve™ is designed to last with stainless alloy construction and internal dust wipers

- Sold as a kit with all parts, fittings and instructions required for installation

- Genuine Products - Manufactured by Schmidt® / Axxiom Manufacturing

- Kit pictured is 1-1/2" Airlines, Electric Deadman - most common

-

- Will transform your blast pot into a pressure hold system

- Retrofit Kit includes:

- Thompson® Valve Series II Metering Valve

- Full pusherline kit

- Automatic air valve and all interconnecting hoses

- Control line strainer and control valve

- Response deadman handle and Twinline

- Does not include muffler or pressure relief valve pictured

- Genuine Parts - Manufactured by Schmidt® / Axxiom Manufacturing

-

- To replace the valves on your pressure release blast pot

- Retrofit Kit includes:

- 1 1/4" Combo Valve

- 1 1/4" MicroValve 3

- Full pusherline kit

- All interconnecting hoses

- Control line strainer and control valve

- Response deadman handle and Deadman line

-

GV214950006

- OEM Replacement Plunger Seal for Large Bore Thompson I, Thompson II, MicroValve II, and MicroValve III valves

- Schmidt / Axxiom part # 2149-500-06

- Note - this product is replacing the purple GV215200006 seal

- Note - this product is also included in the relevant seal kits

GV214950006- OEM Replacement Plunger Seal for Large Bore Thompson I, Thompson II, MicroValve II, and MicroValve III valves

- Schmidt / Axxiom part # 2149-500-06

- Note - this product is replacing the purple GV215200006 seal

- Note - this product is also included in the relevant seal kits

-

- Multi-purpose inline ball valve

- Plated brass corrosion-resistant body

- Full bore design for maximum airflow

- Rated for use up to 600 psi

- Female NPT threaded ports

- Sold individually

-

GVFSV1022Heavy-duty pipe fitting connects flat sand valve to pusher line, blast hose line, and blast pot nipple. Specifications:

- 150# malleable iron wye

- 1-¼" x 1-¼" x 1-¼" standard NPT female threads

GVFSV1022Heavy-duty pipe fitting connects flat sand valve to pusher line, blast hose line, and blast pot nipple. Specifications:- 150# malleable iron wye

- 1-¼" x 1-¼" x 1-¼" standard NPT female threads

-

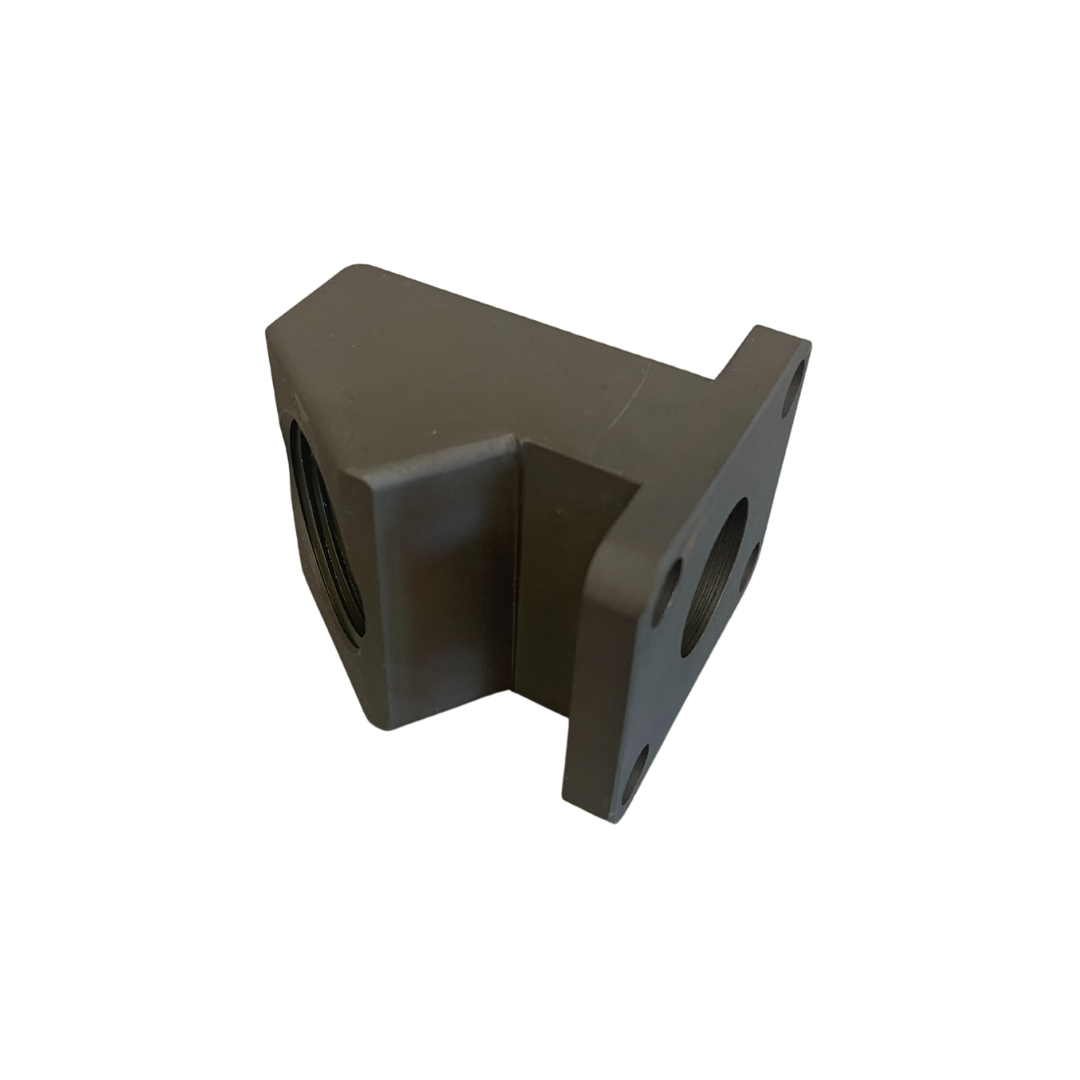

GV215230715

- Replacement direct down base for the 2152-009 Schmidt Jumbo Thompson II Abrasive Metering Valve

- MPN 2152-307-15

GV215230715- Replacement direct down base for the 2152-009 Schmidt Jumbo Thompson II Abrasive Metering Valve

- MPN 2152-307-15

BlastOne is a leading supplier of sandblast valves to the global corrosion control industry. If you are needing abrasive mixing valves, sandblaster metering valves, deadman valves, auto air check, air pressure regulators, exhaust valves, full bore ball or inlet valves, BlastOne is ready to ship to your location.

We are proud suppliers of Schmidt Micro, Thompson and Tera Valves and offer their corresponding service and replacement kits. When it comes to sandblasting valves, parts, and accessories we offer superior equipment.

My Account

My Account