Profile Measurement

BlastOne offers multiple tools that take different approaches to measure the profile of a blasted steel surface. They are simple to use and require minimal or straightforward calibration for accuracy.

These profile measurement tools are able to detect the profile achieved on a newly-blasted surface. Typically, these profile measurements (measured in mils) are specified by the coating manufacturer.

Showing 1–15 of 21 results

-

INDRTRTAPEHLDERRecommended best practice when using the PosiTector RTR 3D is to use these specialized Replica Tape Holders. Very easy to use - just affix the replica tape to the holder, and ensure that the compressible foam is located over the hole in the holder. Once adhered, the replica tape can be simply placed into the probe with no concern about migration of the adhesive onto the probe sensors.INDRTRTAPEHLDERRecommended best practice when using the PosiTector RTR 3D is to use these specialized Replica Tape Holders. Very easy to use - just affix the replica tape to the holder, and ensure that the compressible foam is located over the hole in the holder. Once adhered, the replica tape can be simply placed into the probe with no concern about migration of the adhesive onto the probe sensors.

-

The PosiTector® interchangeable probe inspection system is the backbone of the DeFelsko instrument collection. Save time and cost by choosing a pre-configured multi-probe inspection kit. Details on the most popular inspection kit configurations are as follows:

- Standard Inspection Kits include:

- Choice of either Standard or Advanced Body. (Compare features on the PosiTector Standard and Advanced Bodies on their separate page.)

- PosiTector SPG, Surface Profile Gauge

- PosiTector DPM, Environmental Probe

- Choice of Coating Thickness Probe:

- Ferrous or Combination Ferrous / Non-Ferrous

- Cabled or Integral

- Standard range (0-60 mils / 0-1500 microns) or Extended range (0-250 mils / 0-6mm). More details about the PosiTector 6000 coating thickness probes is on their separate page.

- Extreme Inspection Kit includes:

- Advanced Body

- PosiTector RTR-H, Testex Replica Tape Reader Probe for Surface Profile

- Testex X-tra Coarse tape roll

- PosiTector DPM, Environmental Probe

- PosiTector DPM-L, Remote Environmental Logger

- PosiTector FS, Cabled, Ferrous, Standard Range probe

- Also Includes: In addition to the selected gauge and probes, each kit also includes a carry case, calibration certificate, plastic shims, and more!

- Standard Inspection Kits include:

-

The PosiTector RTR family of instruments is DeFelsko's state-of-the-art solution for surface profile measurement and more. Two different probe models are available and selected features are listed below:

- Familiar. Based on the award-winning PosiTector instrument body platform, the RTR probes are easy to master and use.

- Capable. State-of-the-art technology with 2 models as follows:

- PosiTector RTR H. This 2D version measures surface profile using Testex tape just like a spring micrometer, but with the following enhancements:

- Automatically compensates for the thickness of the Testex film backing.

- Using conventional Testex Coarse or X-Coarse tape, the RTR H calculates linearized measurements automatically, without the complicated averaging process required by analog spring micrometers.

- Stores readings which can be uploaded to PosiSoft, Mac, and smartphone software for professional reporting. Of course, you can keep the physical replica tape as well.

- Ready-to-measure. No calibration adjustment required for most applications.

- PosiTector RTR 3D. This 2D / 3D version offers the same features as the RTR H above, but with these extra features:

- Creates a 3D image of the profile and calculates Peak Density, Peak Count and more - a total of 14 common 2D and 3D surface parameters.

- When paired with the Advanced body, the RTR 3D can download high-res .SDF files for further analysis.

- These 3D surface parameters are proving to be as important (if not more so) than traditional surface profile measurements for predicting coating life. Future proof your instrument purchase against changing specifications by investing in the highly capable PosiTector RTR 3D!

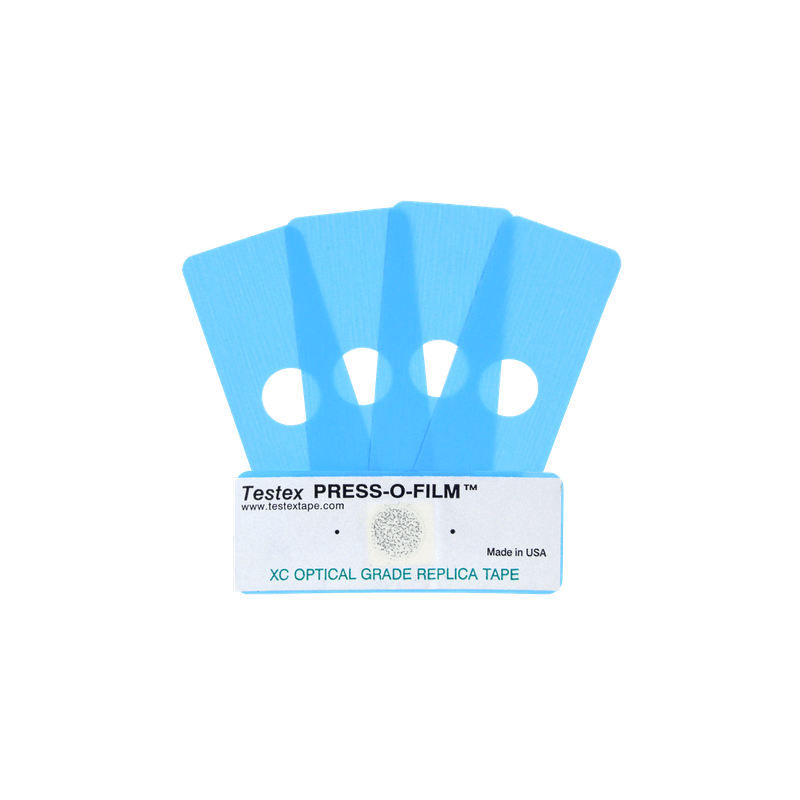

- Note: The PosiTector RTR 3D requires Optical grade Testex tape.

- PosiTector RTR H. This 2D version measures surface profile using Testex tape just like a spring micrometer, but with the following enhancements:

- Configurable. Your choice of RTR probe is available separately (for use with existing PosiTector gage / body), or can be purchased as a kit with your choice of Standard or Advanced body.

-

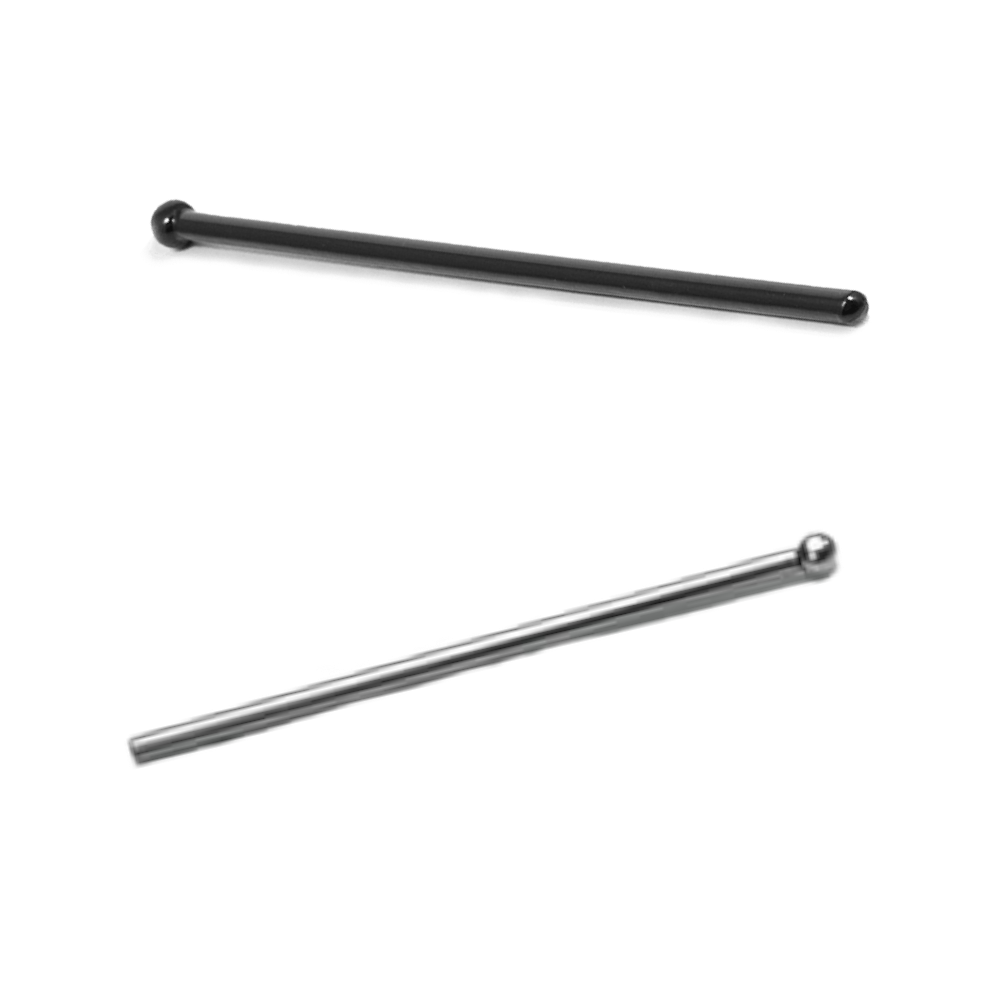

Burnishing tools facilitate accurate and easy use of Testex Press-O-Film replica tape. Multiple types available, as follows:

- Economical plastic. Sold in packs of 10, these have 8mm round ends.

- Durable stainless. Same design as the plastic version, but constructed of stainless steel for long life.

- Burnishing ball. Designed to use with optical grade tape, for use with the RTR 3D probe.

-

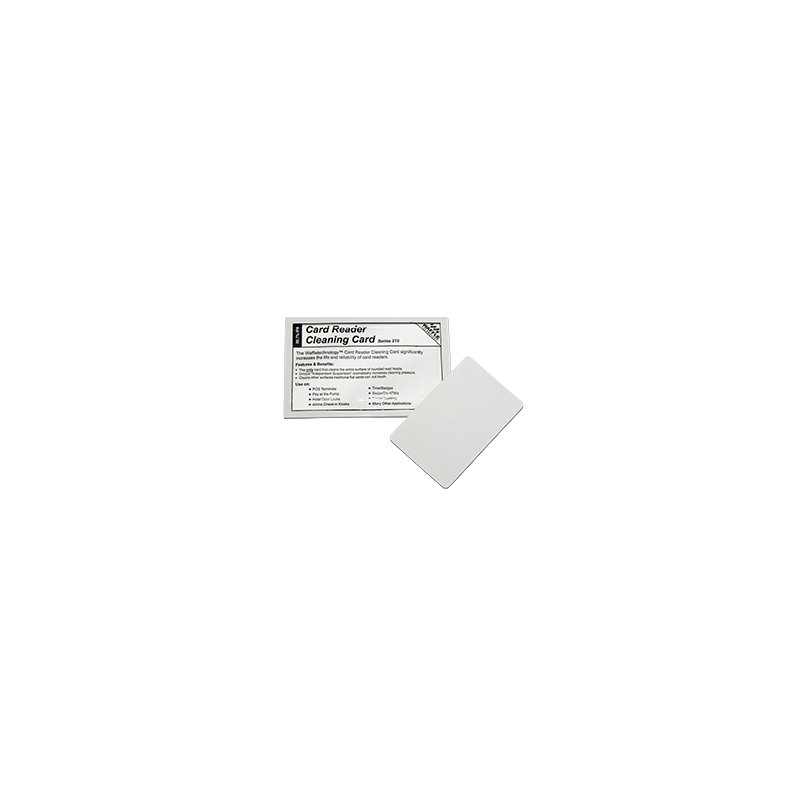

INDRTRCLEANRecommended best practice when performing replica tape tests with PosiTector RTR instruments is to thoroughly clean the anvils (test surfaces) before performing the test. These Cleaning Cards are premoistened with alcohol and are excellent for removing bits of adhesive and debris from the anvils. Each new RTR comes complete with 5 cleaning cards and additional quantities are available here as needed, in packs of 20.INDRTRCLEANRecommended best practice when performing replica tape tests with PosiTector RTR instruments is to thoroughly clean the anvils (test surfaces) before performing the test. These Cleaning Cards are premoistened with alcohol and are excellent for removing bits of adhesive and debris from the anvils. Each new RTR comes complete with 5 cleaning cards and additional quantities are available here as needed, in packs of 20.

-

The PosiTector® SPG - DeFelsko's solution for measuring surface profiles on both metal and concrete surfaces - without the need of Testex® tape. This inspection instrument system is capable and configurable, and has the following highlights:

- Familiar. Built on the tried-and-true PosiTector gauge / body platform, using interchangeable probes.

- Capable. Five separate probe designs available as follows:

- PRBSPG. Integral probe for one-handed use. Measures flat blasted steel.

- PRBSPGS. Cabled probe for enhanced ergonomics and/or access to hard-to-reach areas. Measures flat blasted steel.

- PRBSPGOS. Cabled probe for use on convex curved blasted steel (especially pipes).

- PRBSPGCS. Cabled probe for measuring textured coatings and other surface profile applications.

- PRBSPGTS. Cabled probe for measuring concrete profile.

- Configurable. Available as follows:

- Probe only. Use with your existing PosiTector gauge.

- Standard PosiTector body package with choice of probe.

- Advanced PosiTector body package with choice of probe.

- Note: All PosiTector SPG packages come with case, zero plate / shim, calibration certificate, and more.

-

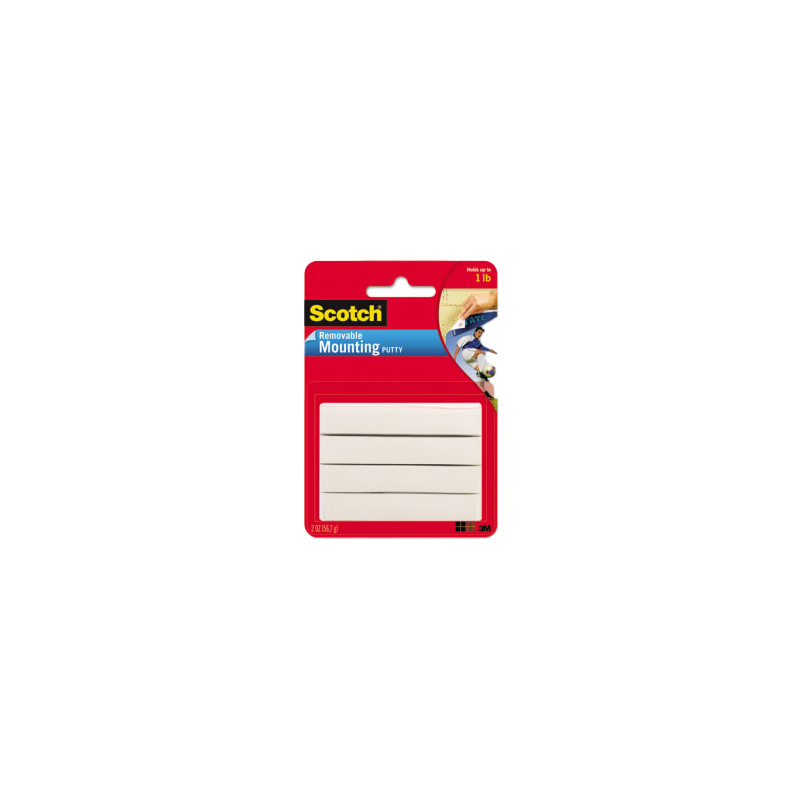

INDRTRPUTTYRecommended best practice when performing replica tape tests is to thoroughly clean the surface before attaching the film to the substrate. This Surface Cleaning Putty is excellent for cleaning steel surfaces of dust and abrasive. One package comes standard with each new PosiTector RTR and additional quantities are available here as needed, in packs of 5.INDRTRPUTTYRecommended best practice when performing replica tape tests is to thoroughly clean the surface before attaching the film to the substrate. This Surface Cleaning Putty is excellent for cleaning steel surfaces of dust and abrasive. One package comes standard with each new PosiTector RTR and additional quantities are available here as needed, in packs of 5.

-

INDSTDRTHelp new staff learn the correct way to take tape impressions for measuring surface profile with this Testex training surface. This training tool is precision cut with inverted v-ridges, simulating a 3.1 mil (78 micron) profile. It is recommended for the trainee to take at least 3 readings with X-Coarse Testex tape to provide practice for the amount of pressure needed to obtain accurate readings. This surface training tool is designed for long life, and can be reused over and over again.INDSTDRTHelp new staff learn the correct way to take tape impressions for measuring surface profile with this Testex training surface. This training tool is precision cut with inverted v-ridges, simulating a 3.1 mil (78 micron) profile. It is recommended for the trainee to take at least 3 readings with X-Coarse Testex tape to provide practice for the amount of pressure needed to obtain accurate readings. This surface training tool is designed for long life, and can be reused over and over again.

-

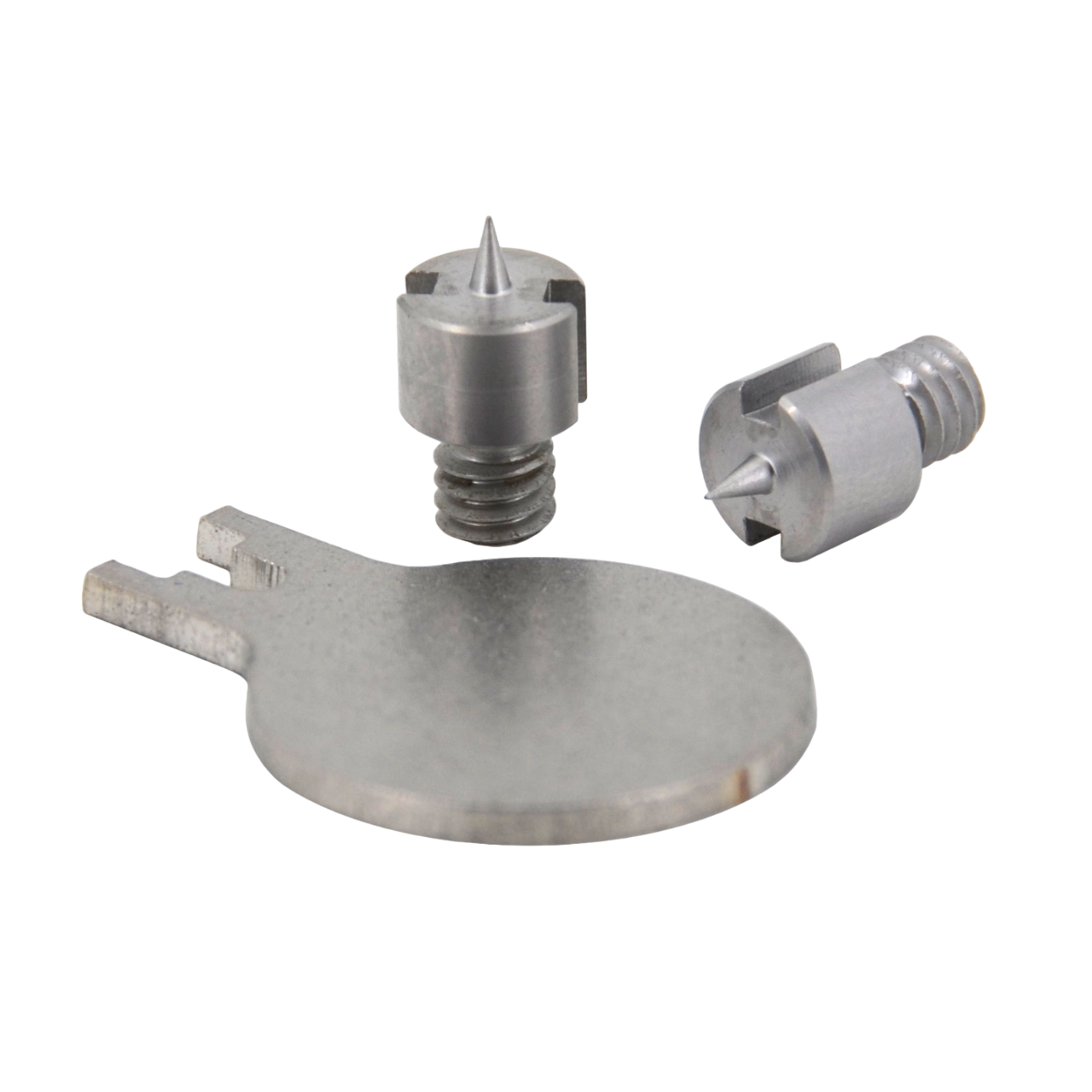

Surface Profile Standards and Shim Sets are used for checking and adjusting calibration on PosiTector SPG, PosiTector RTR (and other depth micrometer probe) instruments. Product details as follows:

- For the PosiTector SPG:

- Certified Standards. Typically used in calibration labs, these are available for any user who desires this level of verification. Includes serialized and traceable height standards mounted to a metal plate. Labeled in both metric and imperial units.

- Certified Shim Set. Premium option for everyday use with any depth micrometer using a fine-pointed probe (as well as the PosiTector SPG). Includes 3 shims at 50/125/500 microns (2, 5, 20 mils).

- Zero Glass Plate / Metal Shim (Non-Certified). For training and quick checks for accuracy, each new SPG unit comes with this verification set, with replacement / additional units also available for purchase here.

- For the PosiTector RTR: (both models unless otherwise noted)

- Certified Shim Set. Premium option to check Peak Height measurements for accuracy verification on the RTR series (as well as other spring micrometer replica tape readers).

- Non-Certified Shim Set (aka Precision Plastic Shim Set). Lower cost version of the above, ideal for everyday accuracy verification.

- Single Check Shim. This non-certified shim comes standard with each new RTR and is available as a replacement if desired, although it is more economical to purchase the above full set.

- Check Tape. This reusable tape is used to verify Peak Density, and is used on the RTR 3D model only.

- For the PosiTector SPG:

-

BlastOne offers all accessories and replacement parts for DeFelsko testing instruments. The PosiTector Surface Profile Gauges have replaceable tungsten carbide tips and are available as follows:

- 60° Angle for ASTM (USA) applications, used in the Integral, Standard Cabled, and Convex Cabled probes.

- 30° Angle for AS 3894.5-C (Australia) applications, also used in the Integral, Standard Cabled, and Convex Cabled probes.

- CS Tip for Textured Coatings probes.

- TS Tip for Concrete Surface probes.

-

INDSPGOSFOOT

- For enhanced stability on 30-45cm (12-18") OD pipes

- For PosiTector SPG OS only

INDSPGOSFOOT- For enhanced stability on 30-45cm (12-18") OD pipes

- For PosiTector SPG OS only

Producing the proper surface profile on a blasted metal surface is important with corrosion control process because it ensures the protective coating’s longevity on structural steel.

If the surface profile doesn’t have an adequate peak-valley height, it may not be able to provide a proper anchor for the coating. This can cause the coating to bubble up or fail prematurely. If there is too large a profile (higher peaks and lower valleys on the steel surface), it will require a greater amount of paint to cover the surface without any noticeable roughness.

My Account

My Account