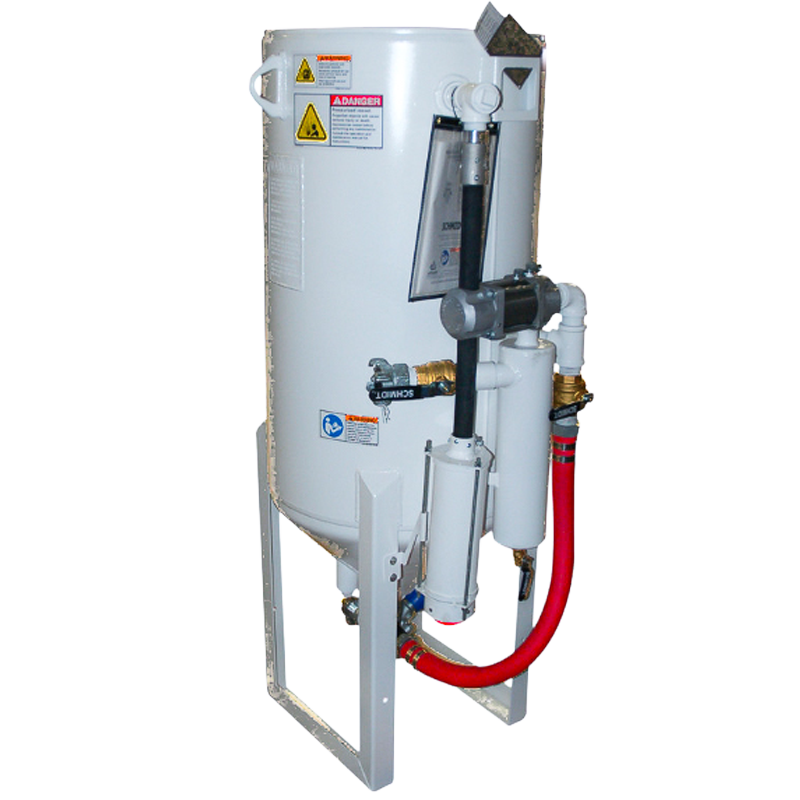

Schmidt® 10 cuft Blast Machine

Sku: P-BMS10CF

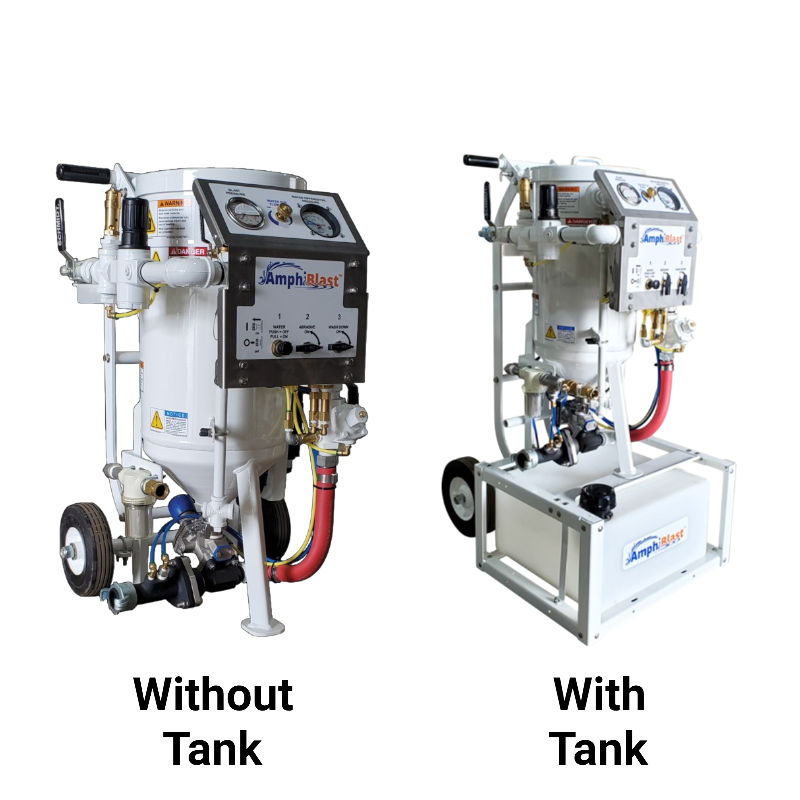

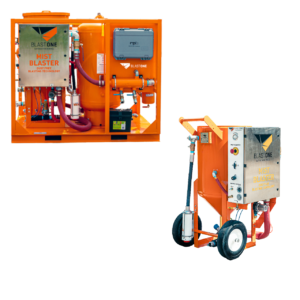

The Schmidt® 10 c.f. Blast Machine is the highest-capacity hand-portable blast pot offered by Schmidt®, purpose-built for extended industrial blasting sessions. With its larger 10 cubic foot capacity, it minimizes refill downtime and increases operator productivity, especially on demanding job sites or in blast room environments. Designed to be highly versatile, this machine is available in both portable (with wheels) and stationary models. It's often built with a second outlet to allow simultaneous operation by two users. This capability makes it a top choice for higher-volume blasting applications.The machine is offered with premium Schmidt abrasive metering valves — MicroValve III®, Thompson® Valve II, and TeraValve® XL — and is rated for full 150 PSI working pressure. Customers can choose from pneumatic or electric control systems to suit their operational setup and climate needs.

All Schmidt equipment is engineered for quality and performance, and provides many years of service.

Additional information:

- 10 cubic foot capacity – up to 3 operator hours of continuous blasting with garnet

- Built with 2 outlet capability - can add a 2nd outlet in the future if needed. Or, buy the 2nd outlet up front!

- Industrial grade construction for heavy duty use

- 150 PSI working pressure w/ high-performance, 1-1/2" piping

- Available in pressure-release or pressure-hold configurations

- The 10cf blast pot is 57" tall (as compared to 51" tall for a 6.5) but is the same 24" diameter.

- BMS1001CMSWH-US: Single outlet pneumatic basic configuration with Combo / MicroValve III pressure-release design. Includes these features:

- VBS II heavy-duty muffler

- Stationary design for blast room use

- BMS1001TERAEP-US: Single outlet electric pressure-hold design with TeraValve. Includes these options:

- High Flow Auto Air Valves (HFAAV), reduces pressure drop for enhanced productivity.

- Moisture Trap to remove residual moisture from compressed air lines. Especially useful when plant compressors are a long distance from the blast booth.

- Union-End Ball Valves (UEBV), allows removal of metering valves without emptying the pot, saves time when servicing the valves.

- Portable design for field or blast room use

- BMS1002TVAP-US: Dual outlet pneumatic pressure-hold design with Thompson II valves w/tungsten sleeves. Includes these options:

- 800cfm High capacity (2-outlet) moisture trap to remove residual moisture from compressed air lines.

- Union-End Ball Valves (UEBV), allows removal of metering valves without emptying the pot, saves time when servicing the valves.

- Portable design for field or blast room use

- Call or Chat for a quote on a pot with other options included if the above do not meet your needs.

Other options available include:

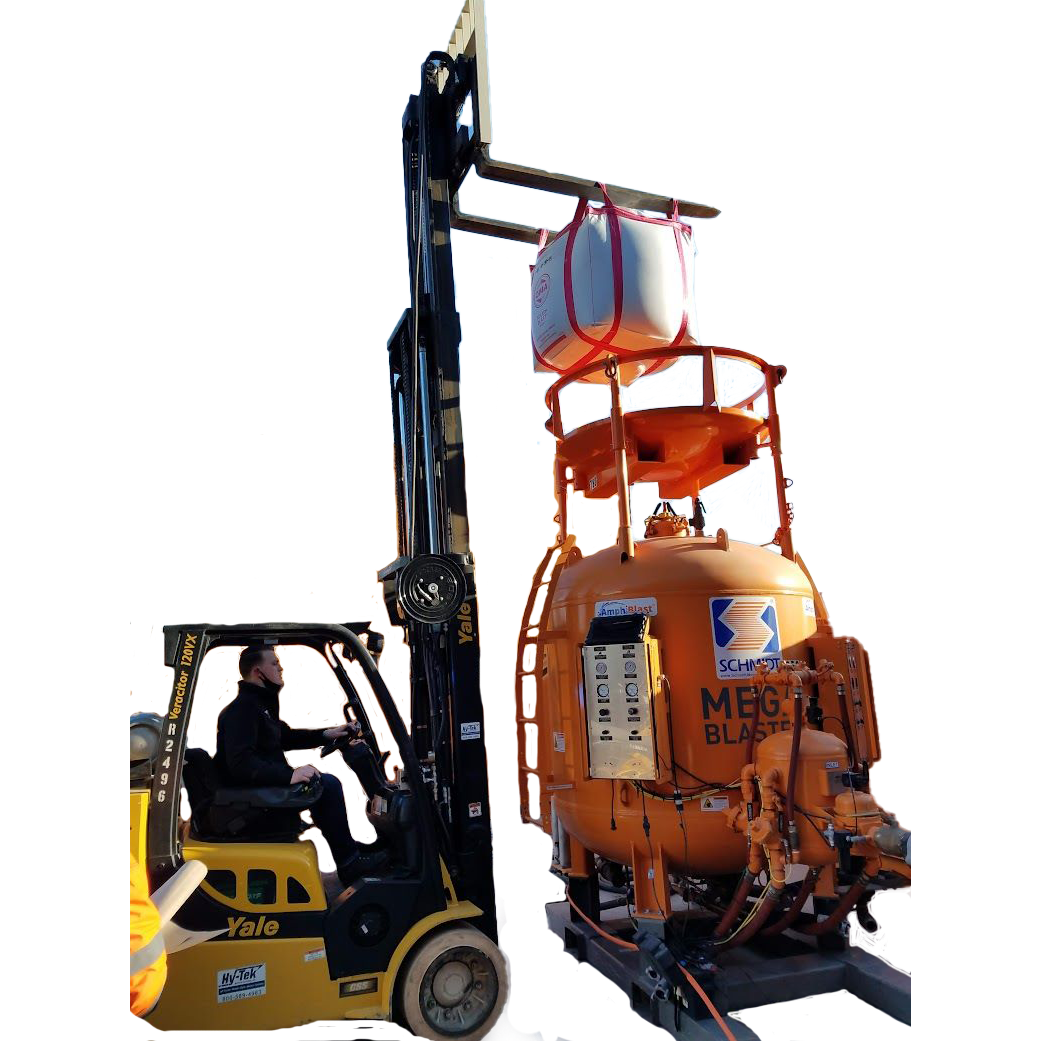

- Spider Plate – Prevents overfilling from overhead abrasive hoppers, ensuring proper sealing of the pop-up valve

- Remote Abrasive Refill – Allows on-the-fly abrasive refilling via remote switch, no manual blowdown needed

- Remote Abrasive Cut-Off (ACO) – Adds a combo-valve to enable the operator to switch off abrasive flow and use the blast hose as an air-only tool.

- Blast Hoses, Bull Hose, and Nozzles - available in a convenient hose/nozzle bundle or purchase a la carte.

- Respirators & PPE - also available in convenient bundles such as the Nova 3 / BlasterAll PPE bundle.

- Aftercoolers or Deliquescent Air Dryers are essential for industrial applications, and are available in a range of capacities to match plant compressor size.

My Account

My Account