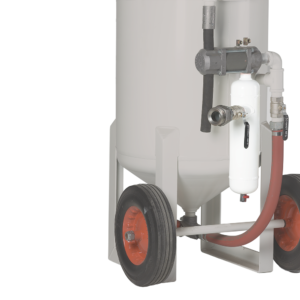

Schmidt® 3.5 cuft Blast Machine

Sku: P-BMS35

The Schmidt® 3.5 Blast Pot is available in several configurations:

Electric or Pneumatic Controls In the USA, many contractors prefer 12v electric deadman controls for 2 reasons: 1) Reduces chances of control system freeze-up in cold weather. 2) Faster deadman response - especially when using over 100' of hose - makes for safer operation.

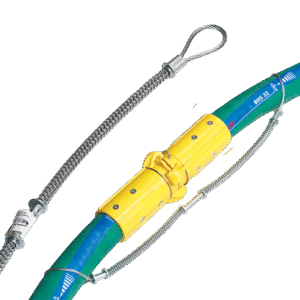

Valve Types (Pressure-hold vs. Pressure-release) TeraValve™ and Thompson® Valve These systems are 'pressure hold', which will substantially shorten the time that blasting will start after actuating the deadman. The TeraValve is the latest generation, and offers some important advantages while costing less. Pressure-hold technology can save up to 15% on abrasive consumption when doing spot blasting, versus a pressure-release system. Combo/MicroValve™ This system is "pressure release", which means when you release the deadman, the pot will depressurize. The Combo/Micro valve system has the same fine metering control as the pressure-hold valves and is a lower initial investment.

More Details The Schmidt® 3.5 cu ft blast pot / blast hopper is an excellent general-purpose abrasive blasting machine, suitable for many different job applications. It is particularly useful for mobile site work. Schmidt abrasive blasting blast pot's ergonomic design features optimize safety and ease of use.

Some of the features that provide these benefits are:

- Schmidt® abrasive blasting pots are manufactured from high-tensile steel. This allows for a reduction in wall thickness while still meeting pressure vessel standards. This results in a lightweight but durable pot.

- Low center of gravity makes the pot easier to pull onto its wheels.

- Large base frames make the pot very stable.

- Semi pneumatic wheels assist moment.

- Large handles, well placed for ease of use.

- Large hand-hole for ease of access to pot interior.

- Blast Hopper Piping is a large diameter high flow design

In addition to good ergonomics, Schmidt® abrasive blasting pots have a spun base rather than a pressed one. This helps to ensure that all the abrasive is emptied out of the pot when blasting. There is no build or bridging of abrasive to prevent complete emptying of the pot. The hemispherical pop-up valve ensures good sealing of the pot even if alignment is not perfect. Polyurethane compound for pop-up valve head and sealing ring extends life and assists seal integrity.

My Account

My Account