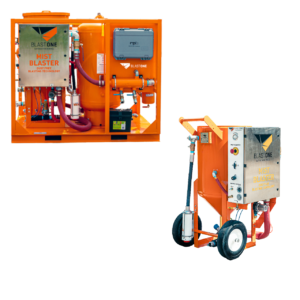

Schmidt® 6.5 cuft Blast Machine

FREE Shipping

30 Day Money-Back Guarantee|Free Returns

90 Day Manufacturer Warranty

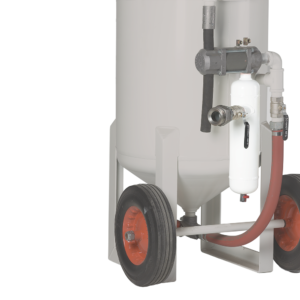

- Most common contractor size, combining portability with productivity

- When using premium garnet media, this pot will blast for around 1.5 hours before you need to refill

- Capacity of 6.5 cu ft, which equates to 950lbs of a dense media like premium GMA Garnet

- Pressure Rating: 150psi

Sold as a Kit which Includes:

- Blast Pot Deadman Control System with 50 feet of control line and handle

- Choice of inlet fitting in either 4-claw or Spud type. Spud will be supplied unless otherwise noted in Order Comments field

BLAST HOSE SOLD SEPARATELY

Genuine Products – Manufactured by Schmidt® /Axxiom Manufacturing

For rental or purchase

Schmidt® 6.5 cuft Blast Machine

SKU: P-BMS65Description

The Schmidt® 6.5 Blast Pot is available in several configurations:

Electric or Pneumatic Controls

In the USA, many contractors prefer 12v electric deadman controls for 2 reasons:

1) Reduces chances of control system freeze-up in cold weather.

2) Faster deadman response – especially when using over 100′ of hose – makes for safer operation.

Valve Types (Pressure-hold vs. Pressure-release)

TeraValve™ and Thompson® Valve

These systems are ‘pressure hold’, which will substantially shorten the time that blasting will start after actuating the deadman. The TeraValve is the latest generation, and offers some important advantages while costing less. Pressure-hold technology can save up to 15% on abrasive consumption when doing spot blasting, versus a pressure-release system.

Combo/MicroValve™

This system is “pressure release”, which means when you release the deadman, the pot will depressurize. The Combo/Micro valve system has the same fine metering control as the pressure-hold valves and is a lower initial investment. Note: In blastroom applications with an overhead hopper to refill blast pots, you can add a Combo valve to the pressure-hold system. This hybrid system (called Remote Abrasive Refill or Remote Depressurization) uses a separate push-button to enable the operator to remotely depressurize the pot, allowing automatic refilling from the storage hopper. This combines the best features of both pressure-hold and pressure-release techologies, saving operator time.

My Account

My Account