Blasting, UHP & Site Equipment

Showing 196–210 of 646 results

-

The Clemco Nozzles for SG-300 Suction Gun are high-performance tungsten carbide nozzles designed to enhance the efficiency and durability of the SG-300 Suction Gun. Available in sizes from #2 to #8, these nozzles ensure optimal abrasive flow and blasting precision. Key Features:

- Durable tungsten carbide nozzles for long-lasting performance.

- Available sizes:

- 1/8" (#2)

- 3/16" (#3)

- 1/4" (#4)

- 5/16" (#5)

- 3/8" (#6)

- 1/2" (#8)

- Air rushing through the suction gun’s mixing chamber draws blast media into the airstream and propels it out through the nozzle for effective blasting.

- Designed for seamless compatibility with the Clemco SG-300 Suction Gun.

- Genuine Clemco product ensures reliable performance and durability in abrasive blasting environments.

-

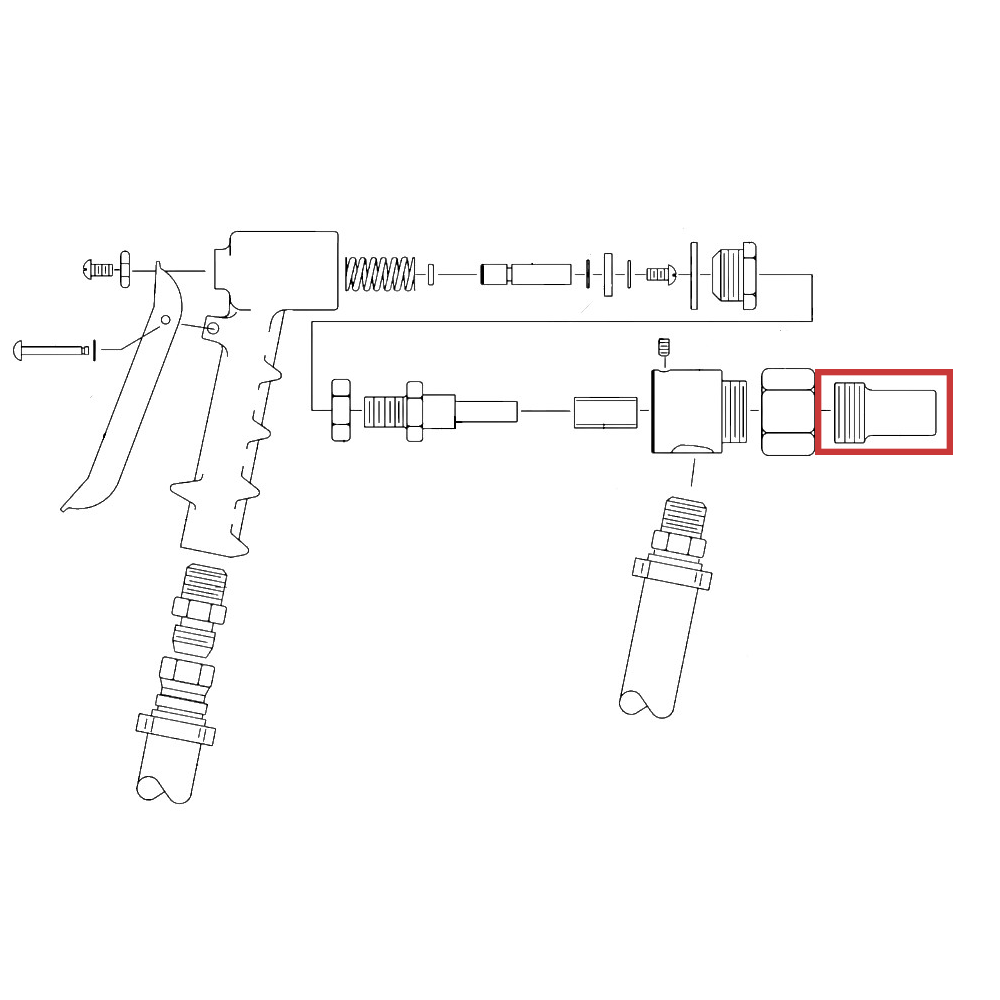

The Clemco BNP Gun Assemblies are industry-leading suction blast guns renowned for their productivity and reliability. Compatible with various nozzle materials sold separately, these genuine Clemco products deliver exceptional performance in abrasive blasting applications. Key Features:

- Widely recognized for productivity and durability in suction blasting operations.

- Includes air jet for efficient abrasive delivery (requires a BNP Gun Nozzle, sold separately).

- Available nozzle materials:

- Ceramic – Cost-effective for light-duty applications.

- Tungsten Carbide – Long-lasting for medium-duty operations.

- Boron Carbide – Maximum durability for heavy-duty use.

- Genuine Clemco product ensures compatibility and reliability.

- Designed for versatility in a wide range of abrasive blasting applications.

-

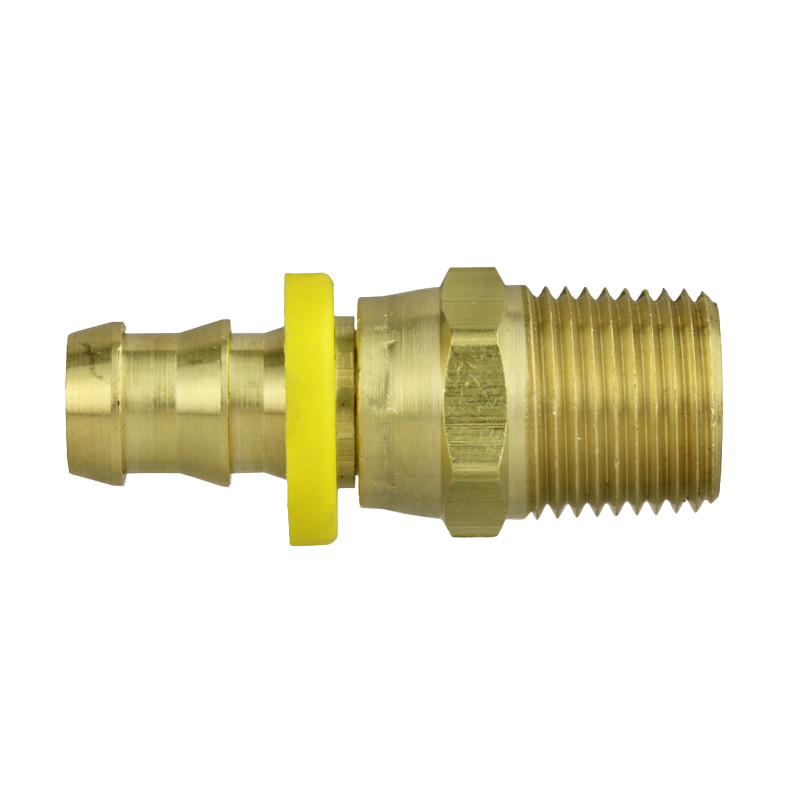

The Brass Nut and Tails Female Pipe Coupling (FP x FP) is a high-quality machined brass fitting designed for hydraulic and pneumatic systems. Manufactured to meet SAE J530 and J531 standards, this pipe coupling can handle pressures up to 1,000 PSI and temperatures ranging from -65°F to +250°F. It’s ideal for industrial applications requiring durable, leak-proof connections.

Main Product Features:

- Solid machined brass construction for enhanced durability

- Female pipe coupling (FP x FP) design

- Performs to SAE J530 and J531 standards Working pressure: 1,000 PSI; Burst pressure: 4,000 PSI

- Temperature range: -65°F to +250°F

- Compatible with hydraulic and pneumatic systems

- Ideal for high-pressure applications in fluid transfer

-

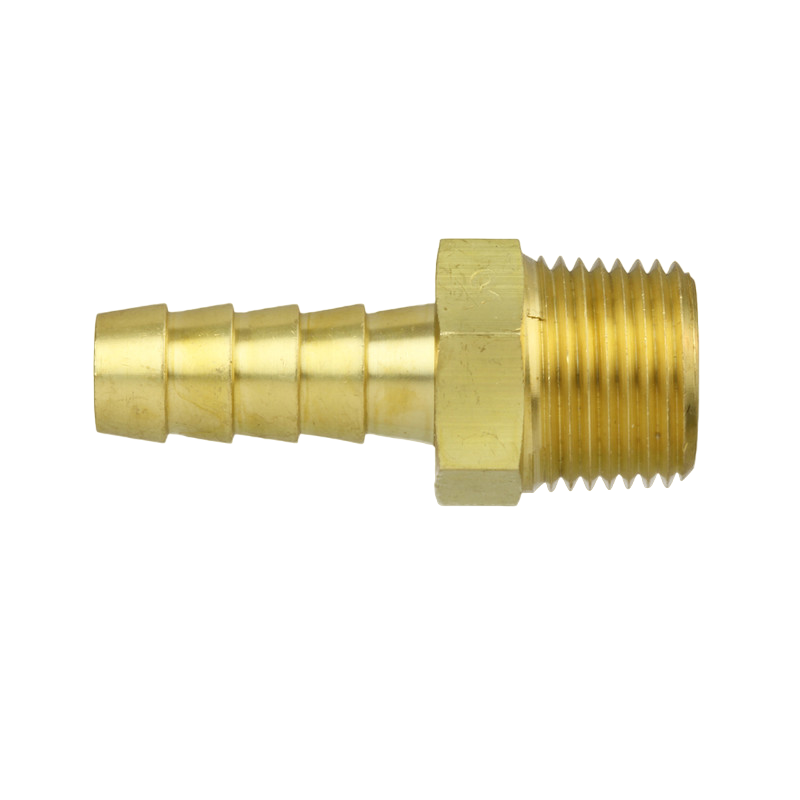

BlastOne offers a full selection of industrial fittings. This group is the Brass Reducer Bushings. Other information is as follows:

- 1st dimension is the NPTF Male Pipe size

- 2nd dimension is the NPTF Female Pipe size

- Operating Pressure Range: 1000 PSI

- Operating Temperature Range: -65 to 250F

-

DMRMCATCSG

BlastOne has the parts to maintain your Clemco® blast equipment. This is the replacement gasket for 1" abrasive trap screen (factory part number 02434).

DMRMCATCSGBlastOne has the parts to maintain your Clemco® blast equipment. This is the replacement gasket for 1" abrasive trap screen (factory part number 02434).

-

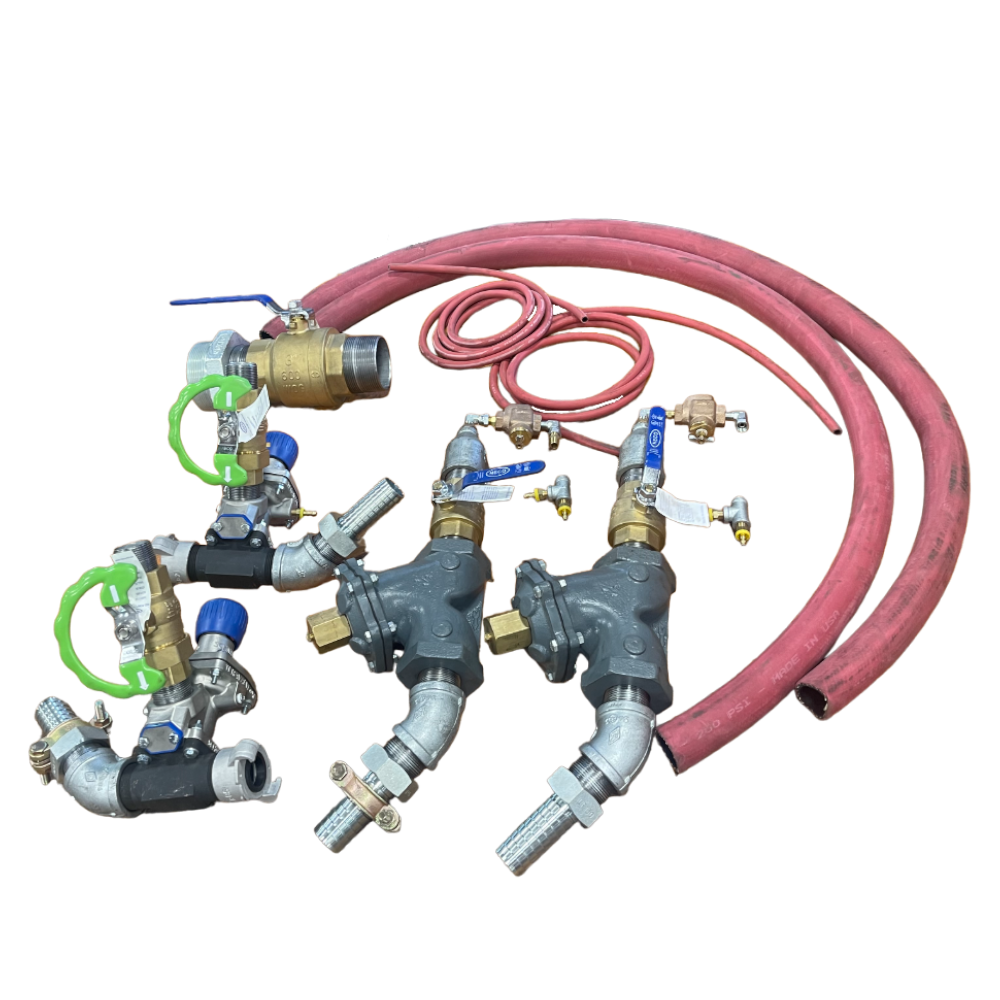

Upgrade old technology Bulk pots from donut valves & pinch valves to state-of-the-art TeraValve systems using a retrofit kit. Available in 2 or 4 outlet configurations. The CEN Mega Exhaust Muffler retrofit kit is a common option that can be conveniently added when performing this retrofit. Note: matching Junction Box is available separately. Retrofitting is recommended only for mega blasters with good structural integrity. These are the parts kits only. BlastOne can perform the retrofit if desired - contact us for pricing and details.

-

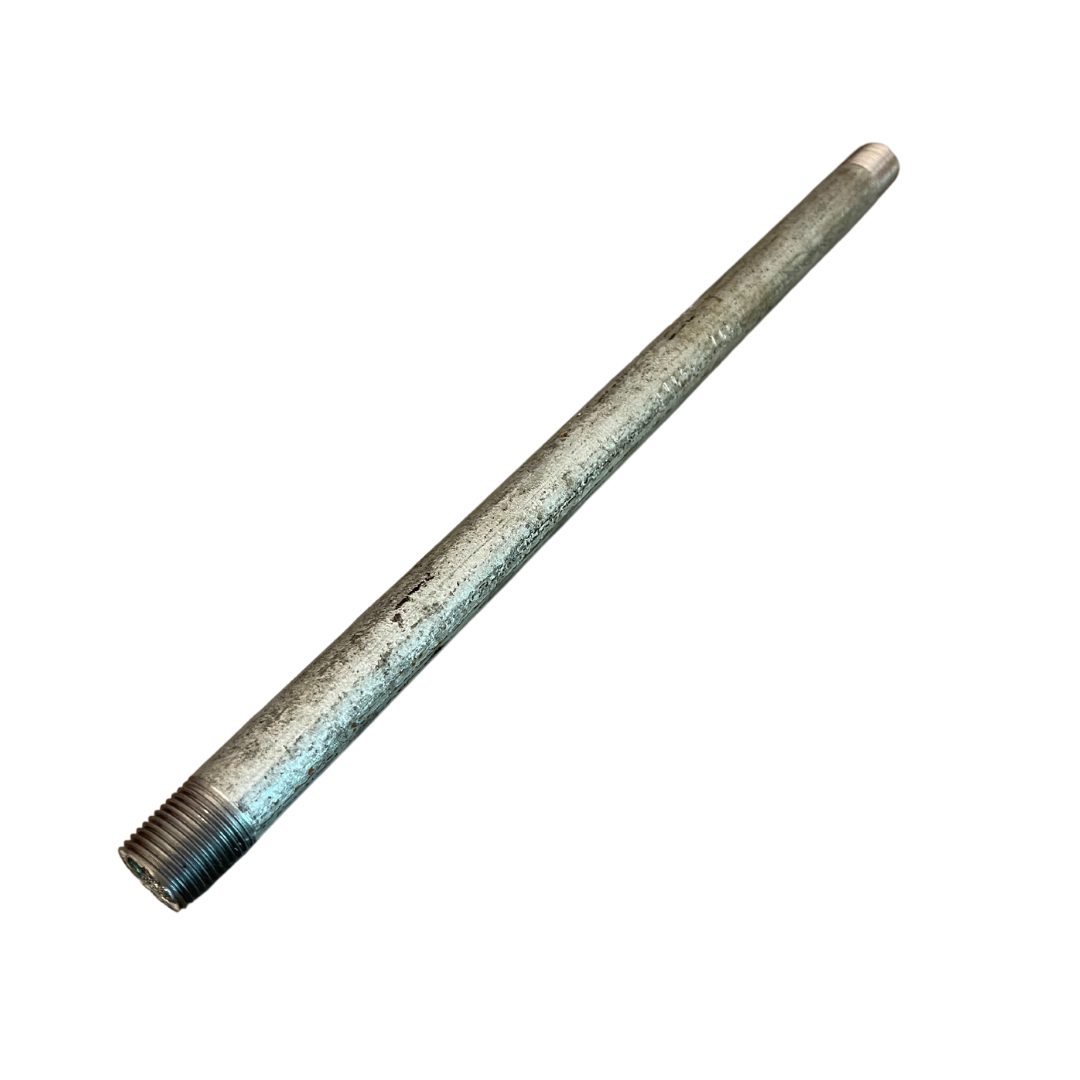

Refresh your Tite Space Invader Blasting Kit with replacement repair rods. Comes in various lengths from 12 - 60 inches.

- Durable and long-lasting construction

- 3/8" Schedule 40, NPT threaded on both ends

- Use with Tite-Space Invaders or with Junior size internal pipe blasters

Our Blasting & UHP Site Equipment category offers everything you need for efficient and effective surface preparation. For abrasive blasting, we supply a variety of blasting pots, nozzles, and blast hoses that ensure consistent media flow and superior performance. If you’re working with ultra-high-pressure water blasting, our UHP pumps and water jetting accessories are engineered for maximum power and precision, making them ideal for removing coatings, rust, and other heavy contaminants. Whether you’re tackling a large industrial project or a specialized cleaning job, our equipment is designed to meet the highest standards of safety and efficiency. Need assistance? Our team is here to provide expert guidance on selecting the best tools for your needs.

My Account

My Account

Blast Equipment

Blast Equipment Blast Nozzles

Blast Nozzles Blast Equipment Parts

Blast Equipment Parts Blast / Air Hose & Couplings

Blast / Air Hose & Couplings Portable Lighting

Portable Lighting Air Dryers

Air Dryers Ventilation & Other Field Equipment

Ventilation & Other Field Equipment UHP & Pressure Washing Equipment

UHP & Pressure Washing Equipment