Blasting, UHP & Site Equipment

Showing 16–30 of 646 results

-

BlastOne’s Fitting Kit for Air Dryers includes everything you need to plumb both the inlet and outlet ports on your air dryer setup. Each kit provides the fittings, brass ball valves, and pipe nipples to hook up air hoses quickly and keep your system tight and reliable.

- Complete fitting kit for air dryer inlet and outlet plumbing

- Includes connection fittings, brass ball valves, and pipe nipples

- Available in 2" 4-Claw, 2" Spud (Boss®), or 3" Spud configurations

- 2" kits are available for either Spud or 4-Claw connections

- Custom dual-style kits available upon request

-

BABL891TLPMAGMNTThe Tactical Light Magnetic Mount for the Western Technology 8910 Body Light makes it easy to secure your blast light to metal surfaces for steady illumination during abrasive blasting or coating work. Designed for durability in harsh jobsite environments, this mount keeps your light stable and hands-free.

- Strong magnetic base for quick, secure attachment

- Compatible with Western Technology 8910 Body Light

- Ideal for blasting booths, tanks, and confined spaces

- Built for industrial and marine coating environments

BABL891TLPMAGMNTThe Tactical Light Magnetic Mount for the Western Technology 8910 Body Light makes it easy to secure your blast light to metal surfaces for steady illumination during abrasive blasting or coating work. Designed for durability in harsh jobsite environments, this mount keeps your light stable and hands-free.- Strong magnetic base for quick, secure attachment

- Compatible with Western Technology 8910 Body Light

- Ideal for blasting booths, tanks, and confined spaces

- Built for industrial and marine coating environments

-

BABLTLPThe Western Technology Tactical Light Stand is built for professionals who need reliable, portable lighting on demanding jobsites. Constructed from durable 6061 T6 aluminum, this non-sparking, modular stand allows for quick deployment and customizable configurations for any lighting setup.

- Durable 6061 T6 aluminum construction

- Non-sparking and corrosion-resistant

- Rapid deployment for field or industrial use

- Compatible with multiple light extensions and accessories

- Made in the U.S.A.

- MPN: Tactical Light Stand (TLS)

BABLTLPThe Western Technology Tactical Light Stand is built for professionals who need reliable, portable lighting on demanding jobsites. Constructed from durable 6061 T6 aluminum, this non-sparking, modular stand allows for quick deployment and customizable configurations for any lighting setup.- Durable 6061 T6 aluminum construction

- Non-sparking and corrosion-resistant

- Rapid deployment for field or industrial use

- Compatible with multiple light extensions and accessories

- Made in the U.S.A.

- MPN: Tactical Light Stand (TLS)

-

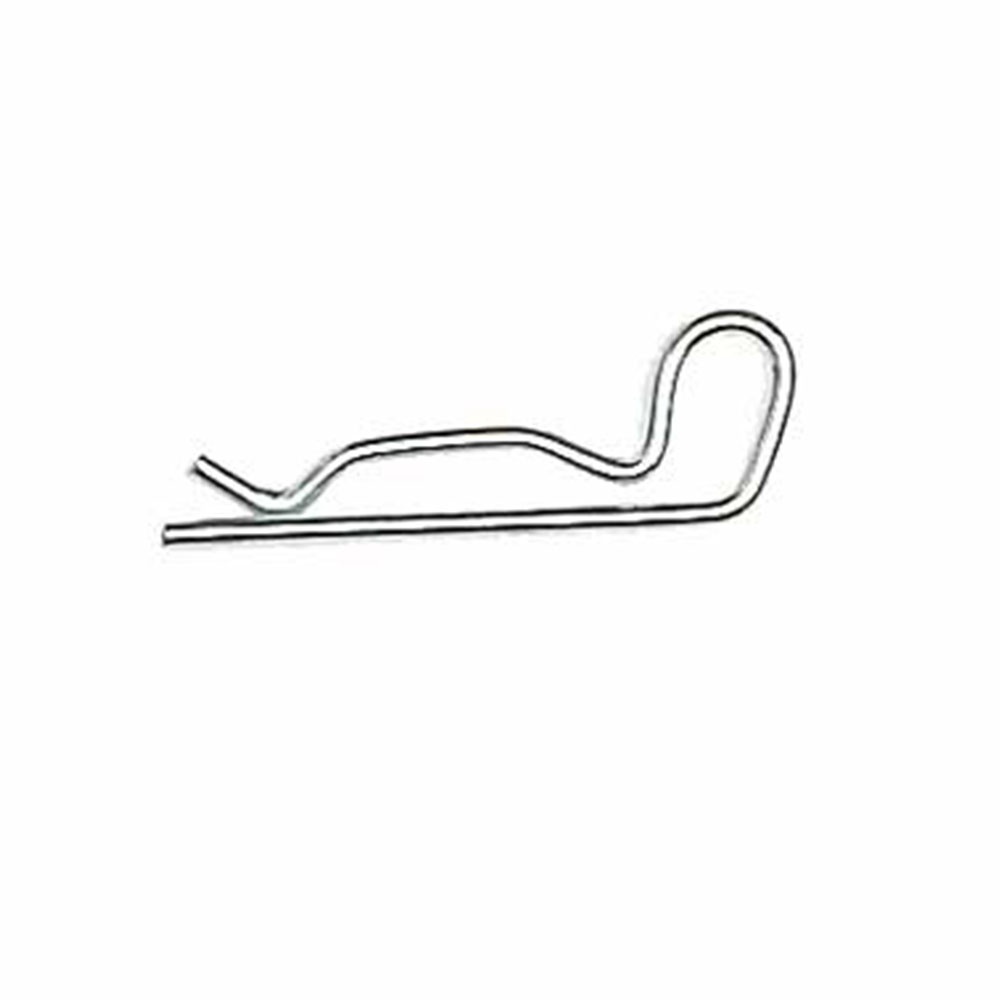

- Must be installed in all blast hose couplings for safety

- Stops the blast hose coupling rotating and disconnecting

- HF-CLP1 is the thin type lock pin (Pack of 25)

- HF-CLP2 is the thick type lock pin (Pack of 25)

- HF-CLP3 is the nylon coupling spring type lock pin (Pack of 10)

- HF-CLP4 is the multi-fit spring type lock pin (Pack of 25)

-

The Schmidt 6.5cf blast pot is the industry’s most popular contractor-sized abrasive blasting machine, designed for larger-scale surface preparation, industrial maintenance, and field service applications. Built with heavy-duty industrial-grade construction, it delivers full 150 PSI working pressure and is configurable with a range of abrasive metering valves and control options to fit demanding jobsite requirements.

- 6.5 cubic foot pot capacity for extended blasting time between refills (up to 950 lbs or 1.5 hours blast time when using a dense media like garnet)

- Heavy-duty construction built for full-shift industrial and contractor use

- Rated for full 150 PSI working pressure

- Choice of abrasive metering valves: Combo/MicroValve III, Thompson II Valve, or TeraValve

- Available with pneumatic or electric control systems and deadman handle options

- Genuine Schmidt® product, manufactured by Axxiom Manufacturing

- Blast Pot Deadman Control System with 50 feet of control line and handle

- Choice of inlet fitting in either 4-claw or Spud type. Spud will be supplied unless otherwise noted in Order Comments field

-

BlastOne's MistBlaster® Wet/Dry Blast Machine is a versatile solution designed to meet the diverse needs of professionals in the blasting industry. This innovative machine, exclusively developed by BlastOne, offers exceptional flexibility with both combo skid and portable configurations, ensuring reliable performance in various project settings.

Features:

- Dual-mode blasting: seamless transition between wet and dry blasting.

- MistBlaster Combo skid options: integrate breathing air packages, air dryers, and more…

- … or Portable configuration: with wheels for easy transport and setup.

- Ultra-low water use: just 1 pint/minute in MistBlast mode.

- Enhanced control panel: 4 operational modes (Dry Blast, Wet Blast, Wash Down, Blow Down).

- Reliable TeraValve® abrasive metering system for consistent performance and pressure-hold technology.

- Compatible with most abrasives in dry mode; garnet or crushed glass recommended for wet mode.

- High-flow connections maintain optimal nozzle performance with very low pressure drop.

- 12v Electric Controls for the fastest and safest deadman action

-

The BlastOne dry combo skid is the ultimate solution for optimizing efficiency and convenience in abrasive blasting for field contractors. By combining a blast machine with an air dryer and an optional breathing air system on a single steel skid, the setup time, equipment transport, and storage are all streamlined and convenient. This all‑in‑one skid drops right in on site: connect the compressor hose, hook up the blast hose, and start blasting—everything built, pre‑plumbed, and road‑ready.

Key features:

- Choice of 6.5 cu ft single outlet or 10 cu ft dual outlet blast pot

- Select either a squat aftercooler or a deliquescent dryer, which come automatically sized for your machine

- Optional breathing‑air bundle: Includes Nova 3 respirator, Radex filter, GX4 CO monitor & breathing air line

- Plug‑and‑play skid design for fast setup, safe transport, compact storage

-

BA31187Clemco 31187 Metering Knob Assembly is an OEM replacement part for MQV-Pro and Grit Wizard abrasive metering valves. It provides accurate control over abrasive flow and fits directly without modification.

- OEM metering knob assembly for Clemco valves

- Fits MQV-Pro and Grit Wizard models

- Controls abrasive flow from the valve

- Complete replacement assembly

- SKU: BA31187

- MPN: 31187

BA31187Clemco 31187 Metering Knob Assembly is an OEM replacement part for MQV-Pro and Grit Wizard abrasive metering valves. It provides accurate control over abrasive flow and fits directly without modification.- OEM metering knob assembly for Clemco valves

- Fits MQV-Pro and Grit Wizard models

- Controls abrasive flow from the valve

- Complete replacement assembly

- SKU: BA31187

- MPN: 31187

-

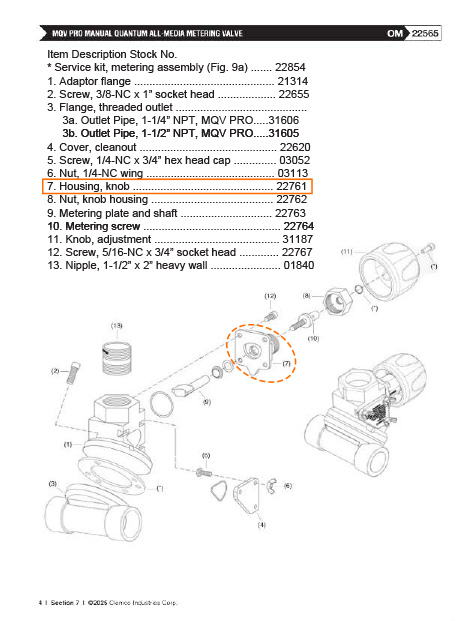

BA22761Clemco 22761 Knob Housing is a genuine OEM part for MQV and MQV-Pro valves used on Clemco pressure-release blast pots. It holds the valve knob assembly in place and allows for proper abrasive flow adjustment.

- OEM housing for MQV and MQV-Pro valve knobs

- Supports accurate abrasive adjustment

- Used in Clemco pressure-release blast pots

- SKU: BA22761

- MPN: 22761

BA22761Clemco 22761 Knob Housing is a genuine OEM part for MQV and MQV-Pro valves used on Clemco pressure-release blast pots. It holds the valve knob assembly in place and allows for proper abrasive flow adjustment.- OEM housing for MQV and MQV-Pro valve knobs

- Supports accurate abrasive adjustment

- Used in Clemco pressure-release blast pots

- SKU: BA22761

- MPN: 22761

-

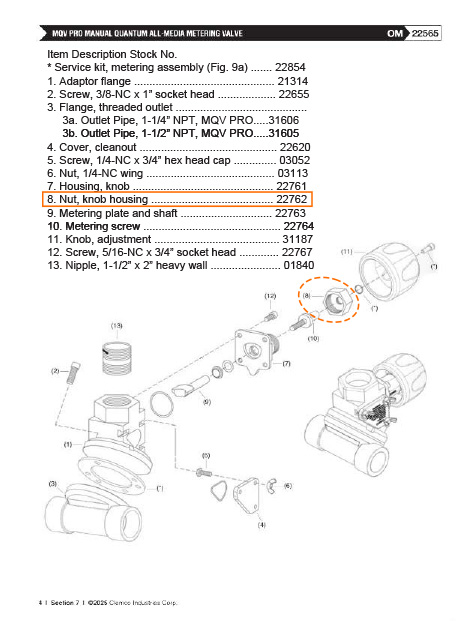

BA22762Clemco 22762 Nut is an OEM replacement part used in the knob housing of MQV and MQV-Pro valves. Designed for pressure-release Clemco blast pots, it keeps the valve knob assembly secure and functional.

- OEM nut for MQV and MQV-Pro knob housing

- Secures knob assembly in place

- Fits Clemco pressure-release blast pots

- Essential for proper valve function and adjustment

- SKU: BA22762

- MPN: 22762

BA22762Clemco 22762 Nut is an OEM replacement part used in the knob housing of MQV and MQV-Pro valves. Designed for pressure-release Clemco blast pots, it keeps the valve knob assembly secure and functional.- OEM nut for MQV and MQV-Pro knob housing

- Secures knob assembly in place

- Fits Clemco pressure-release blast pots

- Essential for proper valve function and adjustment

- SKU: BA22762

- MPN: 22762

-

BA22764Clemco 22764 Metering Screw is a factory OEM replacement for MQV and MQV-Pro valves on pressure-release Clemco blast pots. Keeps abrasive flow steady and consistent during blasting.

- OEM part – fits MQV and MQV-Pro valves

- Controls abrasive media flow

- Built for Clemco pressure-release blast pots

- Restores valve performance with proper fit

- SKU: BA22764

- MPN: 22764

BA22764Clemco 22764 Metering Screw is a factory OEM replacement for MQV and MQV-Pro valves on pressure-release Clemco blast pots. Keeps abrasive flow steady and consistent during blasting.- OEM part – fits MQV and MQV-Pro valves

- Controls abrasive media flow

- Built for Clemco pressure-release blast pots

- Restores valve performance with proper fit

- SKU: BA22764

- MPN: 22764

-

The Clemco MQV-Pro Abrasive Metering Valve offers unmatched control, efficiency, and performance for pressure-release blast machines ranging from 0.5 to 20 cubic feet. Compared to the legacy Clemco MQV valve, the MQV-Pro's compact and advanced valve design improves media flow while significantly reducing media usage and maintenance needs. Key Features:

- Precision metering for improved blasting efficiency

- Compatible with blast machines from 0.5cf to 20cf capacity

- Enhanced durability and wear resistance for longer life

- Valve design promotes smoother media flow and consistent performance with all common abrasives, mineral, slag, or steel.

- Control knob enables precise media adjustment during blasting

- Compact footprint allows for optional service ball valve installation

- Reduces abrasive consumption and system troubleshooting

- Available Sizes:

- MQV-Pro 1/2” (MPN: 31716)

- MQV-Pro 1-1/4" (MPN: 31607)

- MQV-Pro 1-1/2” (MPN: 31608)

-

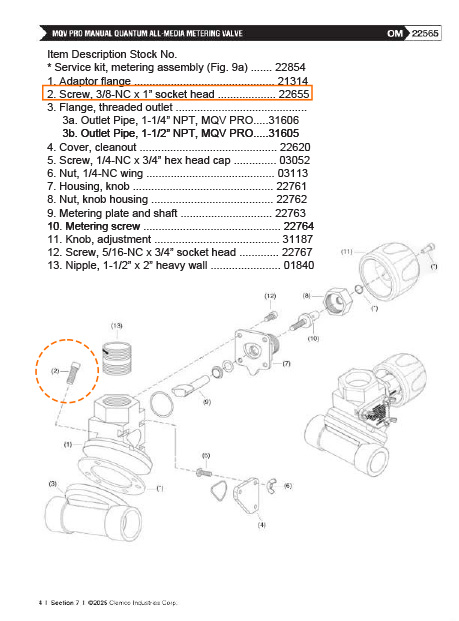

BA22655Clemco 22655 is a 3/8-NC x 1" socket head screw used in MQV, MQV-Pro, AQV, and AQV-H abrasive metering valves. It's a factory OEM replacement for securing key valve components.

- OEM socket head screw for Clemco metering valves

- Fits MQV, MQV-Pro, AQV, and AQV-H models

- 3/8-NC thread, 1" length

- Secures valve parts under pressure and vibration

- SKU: BA22655

- MPN: 22655

BA22655Clemco 22655 is a 3/8-NC x 1" socket head screw used in MQV, MQV-Pro, AQV, and AQV-H abrasive metering valves. It's a factory OEM replacement for securing key valve components.- OEM socket head screw for Clemco metering valves

- Fits MQV, MQV-Pro, AQV, and AQV-H models

- 3/8-NC thread, 1" length

- Secures valve parts under pressure and vibration

- SKU: BA22655

- MPN: 22655

-

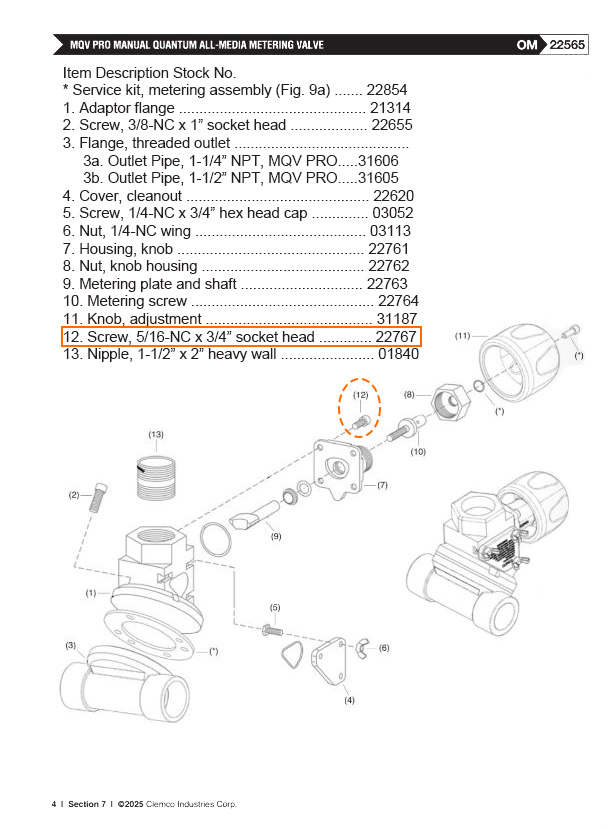

BA22767Clemco 22767 is a 5/16-NC x 3/4" socket head screw used on MQV and MQV-Pro abrasive metering valves. OEM fastener designed to secure valve components under blast conditions.

- OEM socket head screw for MQV and MQV-Pro valves

- 5/16-NC thread, 3/4" length

- Secures internal valve parts

- Used in Clemco pressure-release blast systems

- SKU: BA22767

- MPN: 22767

BA22767Clemco 22767 is a 5/16-NC x 3/4" socket head screw used on MQV and MQV-Pro abrasive metering valves. OEM fastener designed to secure valve components under blast conditions.- OEM socket head screw for MQV and MQV-Pro valves

- 5/16-NC thread, 3/4" length

- Secures internal valve parts

- Used in Clemco pressure-release blast systems

- SKU: BA22767

- MPN: 22767

-

DMRLX1018The DMRLX1018 replacement torsion spring (Clemco MPN 05823) fits RLX deadman handles, both electric and pneumatic. Available individually here, or as part of the pneumatic RLX rebuild kit.

- Individual replacement springs for RLX deadman handles

- Fits electric and pneumatic models

- Two springs included in Clemco 22859 pneumatic service kit

- Sold individually for electric handle maintenance

- SKU DMRLX1018, MPN 05823

DMRLX1018The DMRLX1018 replacement torsion spring (Clemco MPN 05823) fits RLX deadman handles, both electric and pneumatic. Available individually here, or as part of the pneumatic RLX rebuild kit.- Individual replacement springs for RLX deadman handles

- Fits electric and pneumatic models

- Two springs included in Clemco 22859 pneumatic service kit

- Sold individually for electric handle maintenance

- SKU DMRLX1018, MPN 05823

Our Blasting & UHP Site Equipment category offers everything you need for efficient and effective surface preparation. For abrasive blasting, we supply a variety of blasting pots, nozzles, and blast hoses that ensure consistent media flow and superior performance. If you’re working with ultra-high-pressure water blasting, our UHP pumps and water jetting accessories are engineered for maximum power and precision, making them ideal for removing coatings, rust, and other heavy contaminants. Whether you’re tackling a large industrial project or a specialized cleaning job, our equipment is designed to meet the highest standards of safety and efficiency. Need assistance? Our team is here to provide expert guidance on selecting the best tools for your needs.

My Account

My Account

Blast Equipment

Blast Equipment Blast Nozzles

Blast Nozzles Blast Equipment Parts

Blast Equipment Parts Blast / Air Hose & Couplings

Blast / Air Hose & Couplings Portable Lighting

Portable Lighting Air Dryers

Air Dryers Ventilation & Other Field Equipment

Ventilation & Other Field Equipment UHP & Pressure Washing Equipment

UHP & Pressure Washing Equipment