Blast Equipment

Showing 76–90 of 91 results

-

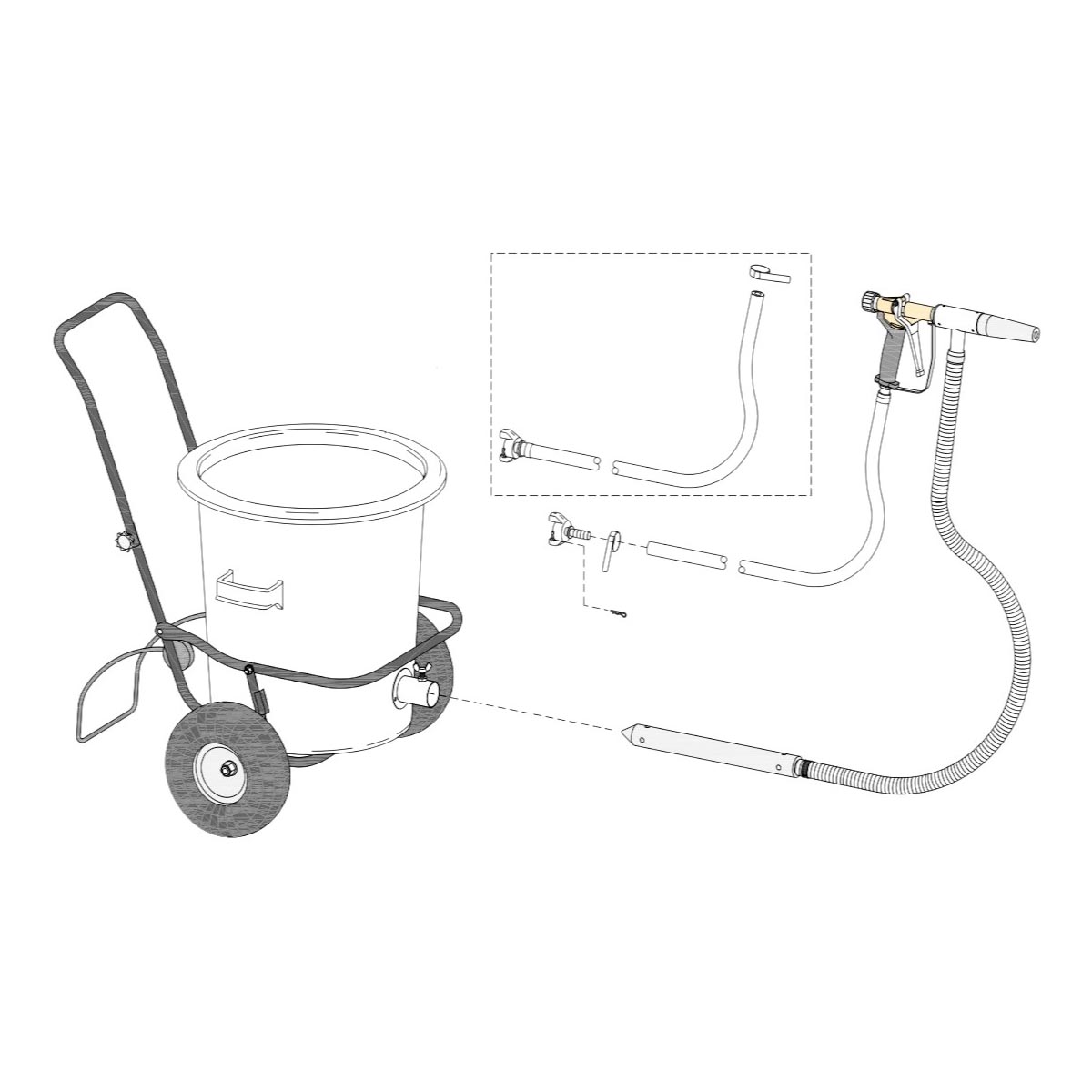

The Clemco Power Suction Gun Packages provide a compact, lightweight suction blasting solution for dry abrasive blasting. Ideal for small jobs or locations where conventional pressure blast setups are inconvenient. Primary Benefits:

- Simple design. No valves, no pressure pots.

- Easy to use. Simply place the suction lance into a bag of abrasive (or into the optional 3cf hopper) to use.

- Highly portable. With an empty weight of 50 pounds including the air / material hose and hopper / cart, the PowerGun package is extremely mobile.

- Power Suction Gun (only), MPN: 100477

- Gun with 16 ft. air/material hoses, MPN: 90253

- Gun with 30 ft. air/material hoses, MPN: 24688

- Gun w/hopper, cart, and 16 ft hoses, MPN: 99860

- Gun w/hopper, cart, and 30 ft hoses, MPN: 24687

- Hopper (3cf) & cart assembly (no gun or hoses), MPN: 99899

-

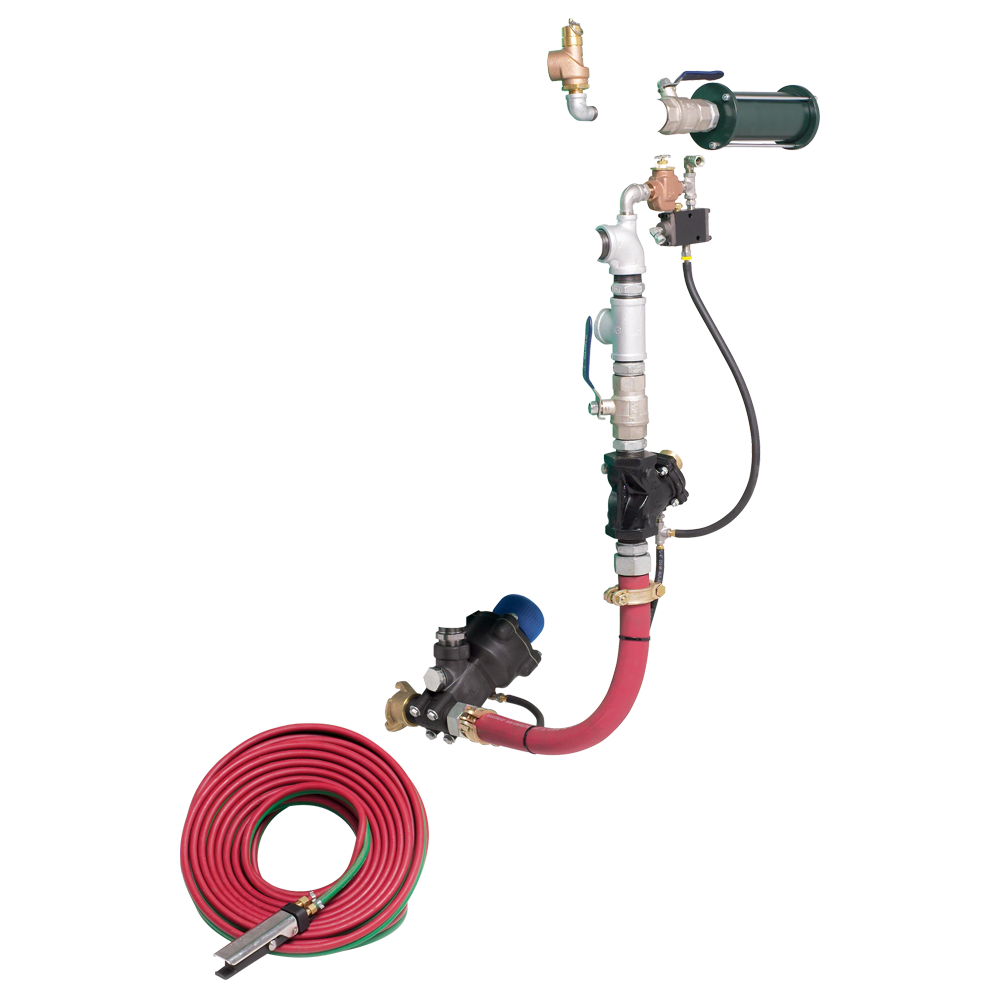

DM2152ACRK

- Pneumatic Complete Retrofit kit includes:

- Triple-line coupled remote control hose

- Control hose connections for air supply

- Auto air valve and Thompson Valve II metering valve

- Pneumatic push-pull abrasive on-off switch

- Response deadman handle

DM2152ACRK- Pneumatic Complete Retrofit kit includes:

- Triple-line coupled remote control hose

- Control hose connections for air supply

- Auto air valve and Thompson Valve II metering valve

- Pneumatic push-pull abrasive on-off switch

- Response deadman handle

-

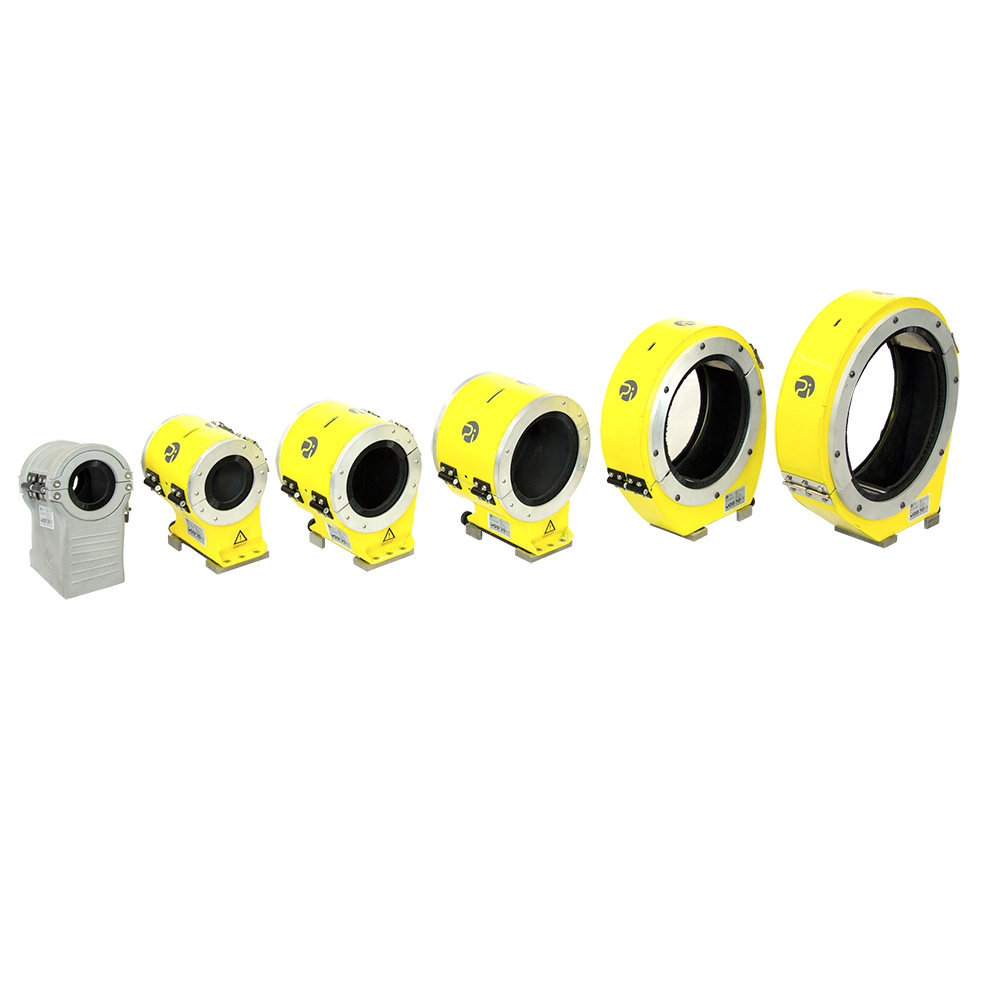

- Compatible with a wide range of blast pots

- Digital display of actual blasting time for individual blast outlets

- Allows you to determine productivity, production rates, assisting project costings, job estimates and scheduling maintenance for common wear items

- System available to run off pneumatic and electric deadman controls

- Triggered instantly by the deadman signal, so you get actual blasting hours

- Options available for single and multiple outlets.

-

EB500FOR RENTAL OR PURCHASE

- Ideal for horizontal steel surfaces and marine maintenance

- Center-fed blast wheel design for efficient abrasive propulsion

- Closed-circuit blasting reduces dust and recovery time

- Modular design for easy access in restricted areas

- Blasting speed between 215-377 sq.ft / 20-35 m² per hour

- 15 hp, 460 v, 32 amp, 3-phase power requirements

- 827 lbs./350 kgs weight

- 19"/600 mm manway compatible

- 13¾″/350 mm blasting pattern width

- Compatible with Blastrac EBDC-23 dust collector/vacuum

EB500FOR RENTAL OR PURCHASE- Ideal for horizontal steel surfaces and marine maintenance

- Center-fed blast wheel design for efficient abrasive propulsion

- Closed-circuit blasting reduces dust and recovery time

- Modular design for easy access in restricted areas

- Blasting speed between 215-377 sq.ft / 20-35 m² per hour

- 15 hp, 460 v, 32 amp, 3-phase power requirements

- 827 lbs./350 kgs weight

- 19"/600 mm manway compatible

- 13¾″/350 mm blasting pattern width

- Compatible with Blastrac EBDC-23 dust collector/vacuum

-

EB350FOR RENTAL OR PURCHASE

- The Blastrac EBE 350 is designed for blasting horizontal surfaces

- It is easily dissembled and reassembled for limited access projects such as a storage tank.

- Parts will fit through a 19" Man way

- Blasting Pattern Width of 13-3/4"

- Other Brands and Sizes available - Call us for pricing

EB350FOR RENTAL OR PURCHASE- The Blastrac EBE 350 is designed for blasting horizontal surfaces

- It is easily dissembled and reassembled for limited access projects such as a storage tank.

- Parts will fit through a 19" Man way

- Blasting Pattern Width of 13-3/4"

- Other Brands and Sizes available - Call us for pricing

-

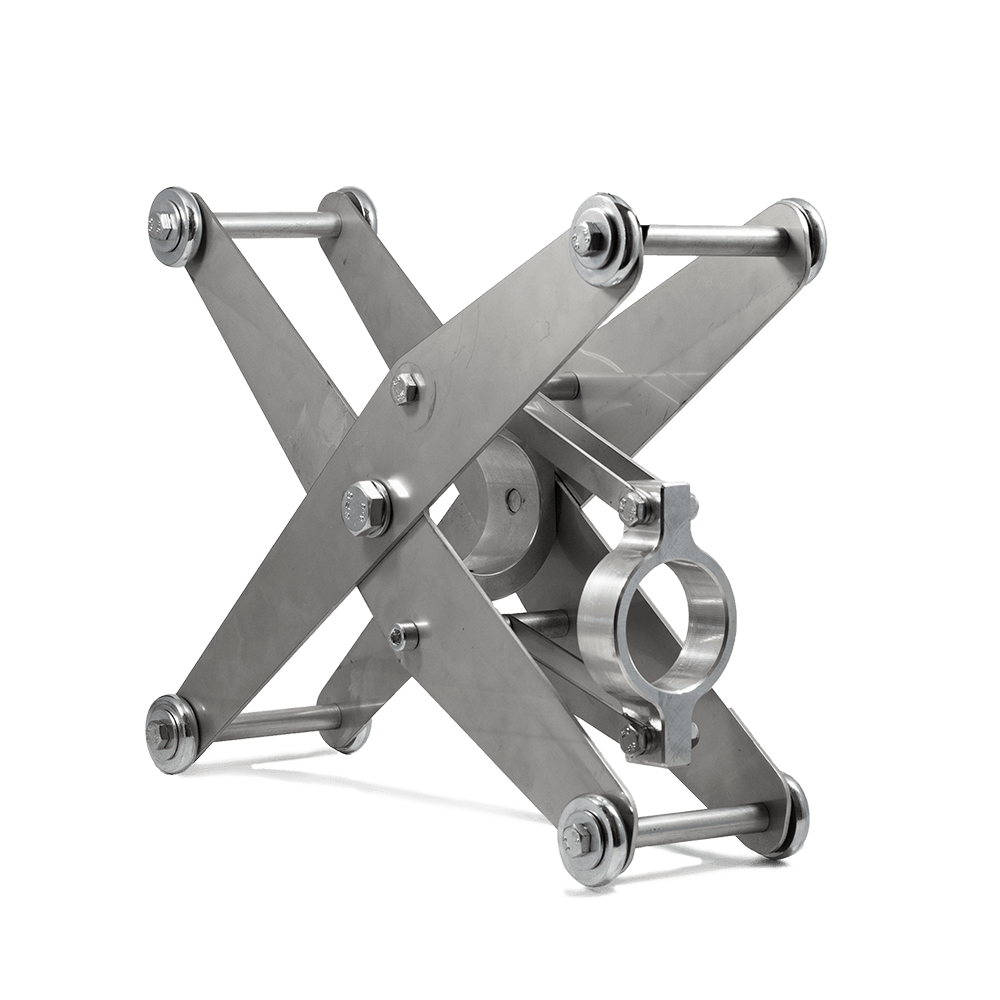

BNATC360BOLT

- Replacement bolt for the Internal Pipe 360° Blast Nozzle

- Sold - individually

BNATC360BOLT- Replacement bolt for the Internal Pipe 360° Blast Nozzle

- Sold - individually

-

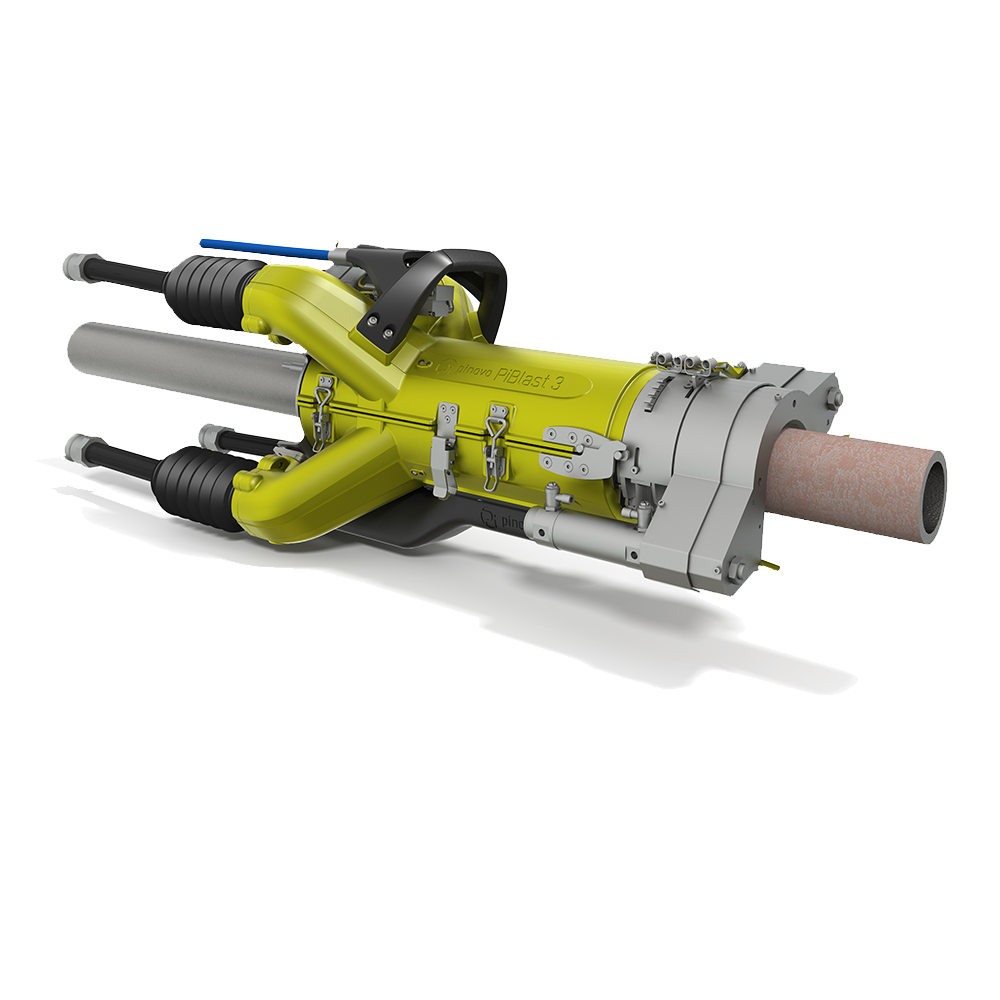

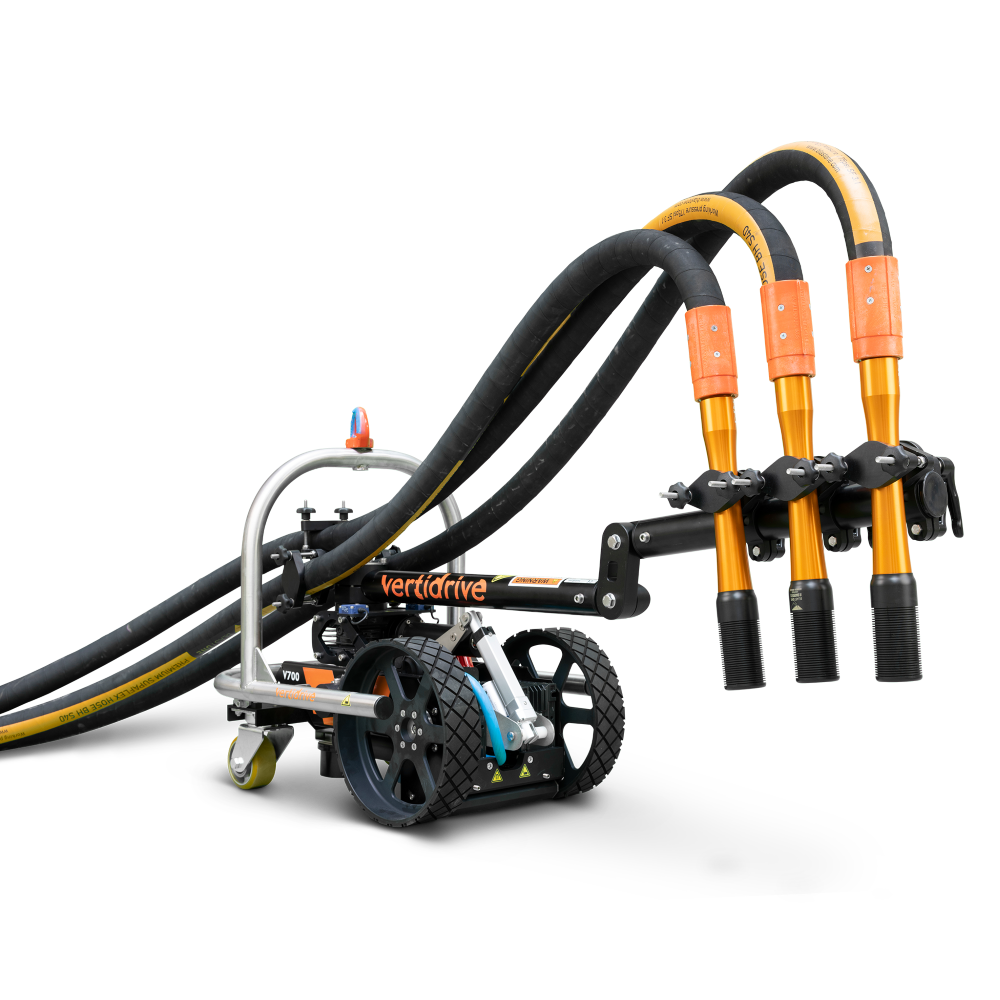

IPRIPTBFOR RENTAL OR PURCHASE

- Ideal for blasting penstocks, tunnels, pipelines, wind towers, etc.

- Offers full 360 degree coverage of pipe internals

- Self-propelled forward or reverse motion

- Can blast pipelines 3' - 32' in diameter

- Lowers labor costs as much as 75% compared with manual blast-pot operations

- Eliminates inconsistencies commonly found with manual blasting

IPRIPTBFOR RENTAL OR PURCHASE- Ideal for blasting penstocks, tunnels, pipelines, wind towers, etc.

- Offers full 360 degree coverage of pipe internals

- Self-propelled forward or reverse motion

- Can blast pipelines 3' - 32' in diameter

- Lowers labor costs as much as 75% compared with manual blast-pot operations

- Eliminates inconsistencies commonly found with manual blasting

-

SBPL01Wall mounted personnel lift, for use in blast rooms. Capable of 3-axis travel, utilizes heavy-duty design to operate in harsh blasting environments.SBPL01Wall mounted personnel lift, for use in blast rooms. Capable of 3-axis travel, utilizes heavy-duty design to operate in harsh blasting environments.

-

BA120000001

- Suits Axxiom/Schmidt Moisture Separators

- Genuine OEM Part

- AFMSH800 and AFMSH1600

- Often purchased with BA7032005 Handle Bar Grip

BA120000001- Suits Axxiom/Schmidt Moisture Separators

- Genuine OEM Part

- AFMSH800 and AFMSH1600

- Often purchased with BA7032005 Handle Bar Grip

-

BA871098627

- Suits Blast Pot timer

- Pressure Switch to allow hour counter to count actual blasting hours

- Working PSI range of 10-150 PSI

- Sold Individually

BA871098627- Suits Blast Pot timer

- Pressure Switch to allow hour counter to count actual blasting hours

- Working PSI range of 10-150 PSI

- Sold Individually

-

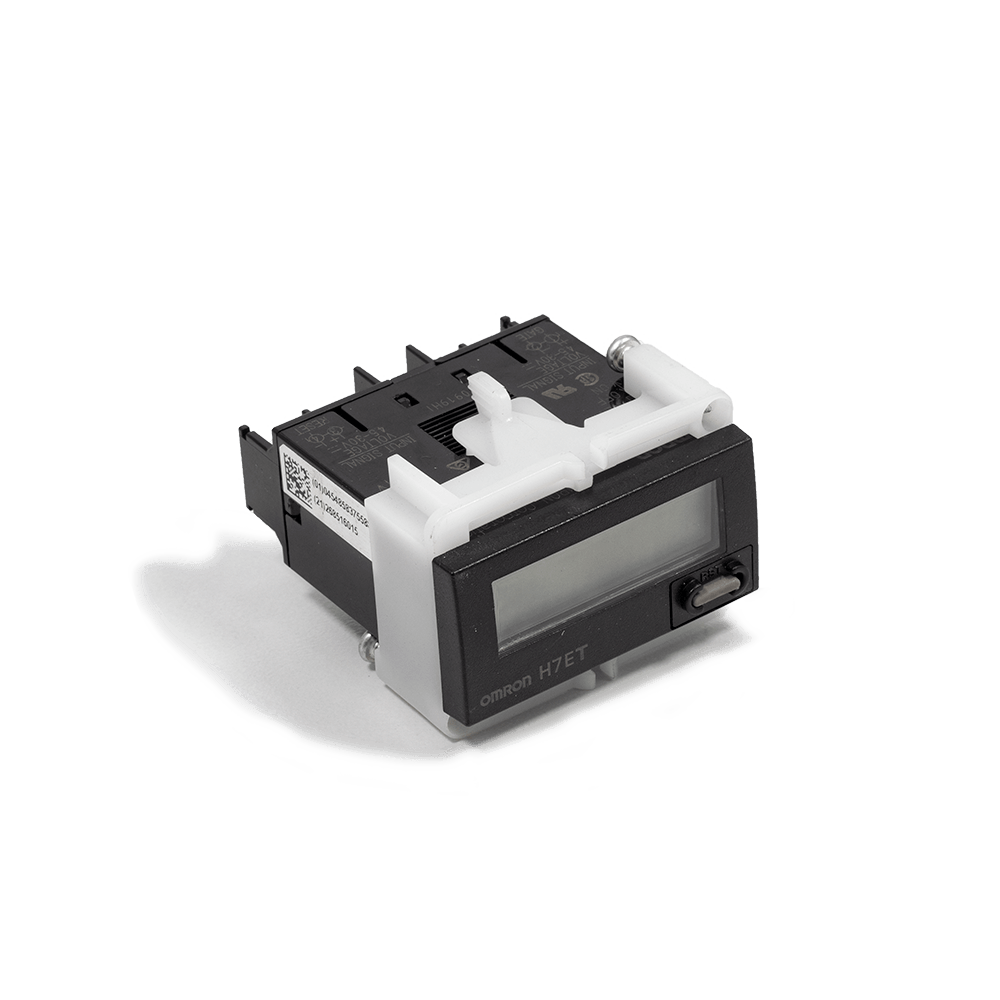

BA7124889

- Suits Blast Pot timer

- Suit No Voltage Applications

- Used to measure actual hours spent blasting

- LCD Timer with Built-In Battery

- Sold Individually

BA7124889- Suits Blast Pot timer

- Suit No Voltage Applications

- Used to measure actual hours spent blasting

- LCD Timer with Built-In Battery

- Sold Individually

-

BAWH10110V

- Designed for use with the rotorblast and cone blasters when ID blasting

- Semi-automatically feeds the blast hose at a consistent rate through the pipe being blasted

- Ensures a consistent blast pattern vs manual handling of the hose

BAWH10110V- Designed for use with the rotorblast and cone blasters when ID blasting

- Semi-automatically feeds the blast hose at a consistent rate through the pipe being blasted

- Ensures a consistent blast pattern vs manual handling of the hose

-

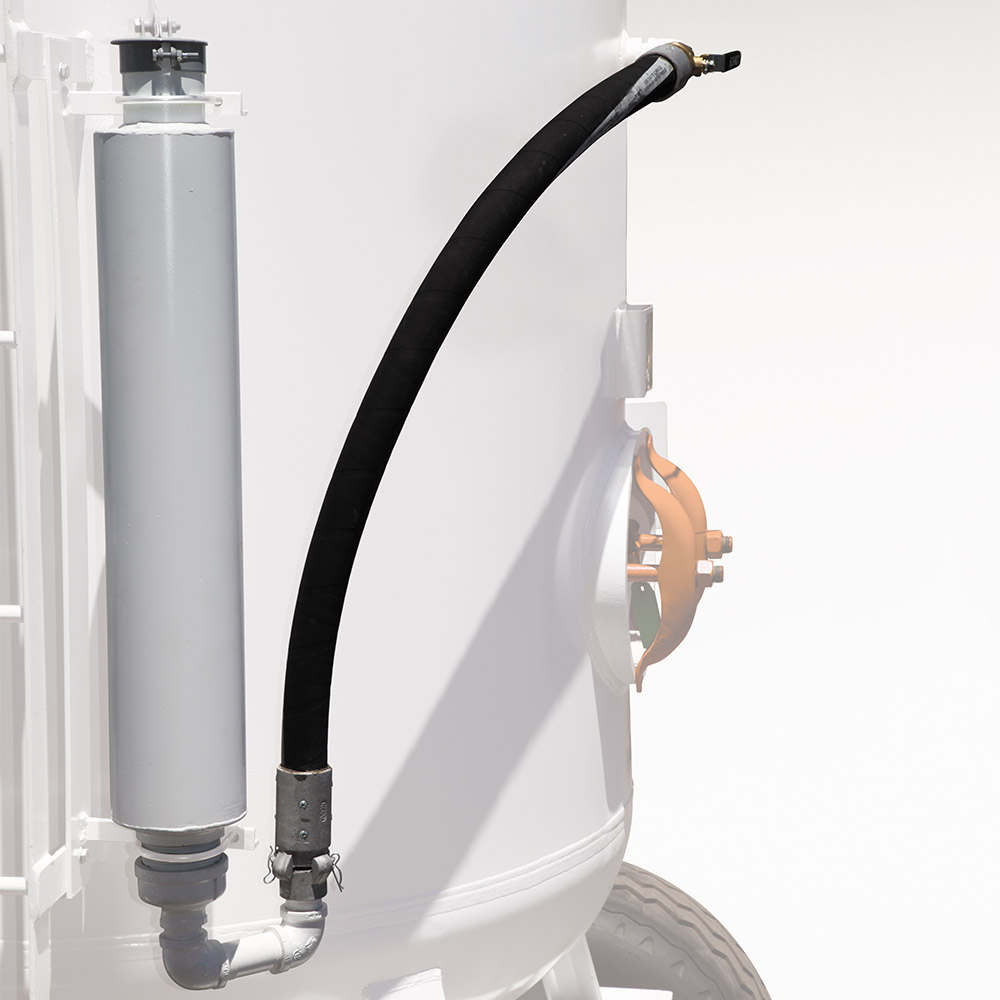

DMMEM100KIT

The Controlled Expansion Nozzle (CEN) Muffler Kit by Axxiom / Schmidt for Mega Pots significantly improves safety as well as reducing blowdown noise.

- Using a CEN muffler removes the risk of freeze-up at the vent. Without this muffler, dangerous pressure can remain in the pot due to vent freeze-up. Injury or death can result to an operator who removes the abrasive loading cover under pressure.

- In addition, noise levels during blowdown without a CEN can exceed 140db. With the CEN, the noise is reduced to 92db.

- The kit includes a 3" NPT thread connection. As mounting brackets are not included in the kit (due to the restriction on welding on a pressure vessel after certification), customer will need to decide best place for mounting, possibly using the ladder. BlastOne technicians are available - contact us if any questions.

DMMEM100KITThe Controlled Expansion Nozzle (CEN) Muffler Kit by Axxiom / Schmidt for Mega Pots significantly improves safety as well as reducing blowdown noise.

- Using a CEN muffler removes the risk of freeze-up at the vent. Without this muffler, dangerous pressure can remain in the pot due to vent freeze-up. Injury or death can result to an operator who removes the abrasive loading cover under pressure.

- In addition, noise levels during blowdown without a CEN can exceed 140db. With the CEN, the noise is reduced to 92db.

- The kit includes a 3" NPT thread connection. As mounting brackets are not included in the kit (due to the restriction on welding on a pressure vessel after certification), customer will need to decide best place for mounting, possibly using the ladder. BlastOne technicians are available - contact us if any questions.

Why Choose BlastOne’s Blast Equipment?

BlastOne’s blast equipment stands out for its reliability and innovation. Features like ergonomic designs, efficient media usage, and compatibility with various abrasives make our equipment a preferred choice. Our products are backed by expert support and comprehensive training resources, ensuring you get the most out of your investment.

Stay ahead in your projects with equipment that meets stringent industry standards and adapts to evolving needs. Trust BlastOne for solutions that enhance productivity and deliver consistent results.

My Account

My Account

Small Blast Pots

Small Blast Pots Contractor Blast Pots

Contractor Blast Pots Specialty Blast Pots

Specialty Blast Pots MistBlaster Wet / Dry Pots

MistBlaster Wet / Dry Pots Mega Bulk Blasters

Mega Bulk Blasters Robotic / Vertidrive Equipment

Robotic / Vertidrive Equipment Track Blasters

Track Blasters Internal Pipe (ID) Systems

Internal Pipe (ID) Systems Blast Machine Accessories

Blast Machine Accessories